Neon_Nightrider

Member

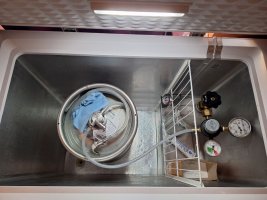

Having a strange issue....

I built a Keezer got it running a while back, and the first 2 commercial kegs (Shiner and Miller) as well as 2 corny keg home brew went perfect!

No Issues with back-feeding CO2 or dispensing issues on the ball lock Corny, or the D-style commercial coupler.

The Inkbird is keeping the temp in the delta I want; and the temp probe is coupled well with the heat sink and reads within a degree of a merc. thermo.

Then all of a sudden without warning.

Now its just foam.

All pressures are set right according to temp and manufacture recommendation.

~15psi at 38-45 degree F

Picnic tap is a Stainless Steel Torpedo Keg model that has been cleaned thoroughly.

Regulator is rebuilt and reading correctly +- 0.5 to the bench gauge.

Tap is a D System Keg Coupler from Krome Dispense (new, as I thought the coupler I had was bad.)

I have checked everything. What do you think it is before I replace the regulator, as that's the only second hand part I still have, and want a dual reg.

Edit : I rest the beer 2 hours after transport before taping, lock coupler, purge valve, match pressure, purge valve.

CO2 system has no leaks.

I built a Keezer got it running a while back, and the first 2 commercial kegs (Shiner and Miller) as well as 2 corny keg home brew went perfect!

No Issues with back-feeding CO2 or dispensing issues on the ball lock Corny, or the D-style commercial coupler.

The Inkbird is keeping the temp in the delta I want; and the temp probe is coupled well with the heat sink and reads within a degree of a merc. thermo.

Then all of a sudden without warning.

Now its just foam.

All pressures are set right according to temp and manufacture recommendation.

~15psi at 38-45 degree F

Picnic tap is a Stainless Steel Torpedo Keg model that has been cleaned thoroughly.

Regulator is rebuilt and reading correctly +- 0.5 to the bench gauge.

Tap is a D System Keg Coupler from Krome Dispense (new, as I thought the coupler I had was bad.)

I have checked everything. What do you think it is before I replace the regulator, as that's the only second hand part I still have, and want a dual reg.

Edit : I rest the beer 2 hours after transport before taping, lock coupler, purge valve, match pressure, purge valve.

CO2 system has no leaks.

Attachments

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)