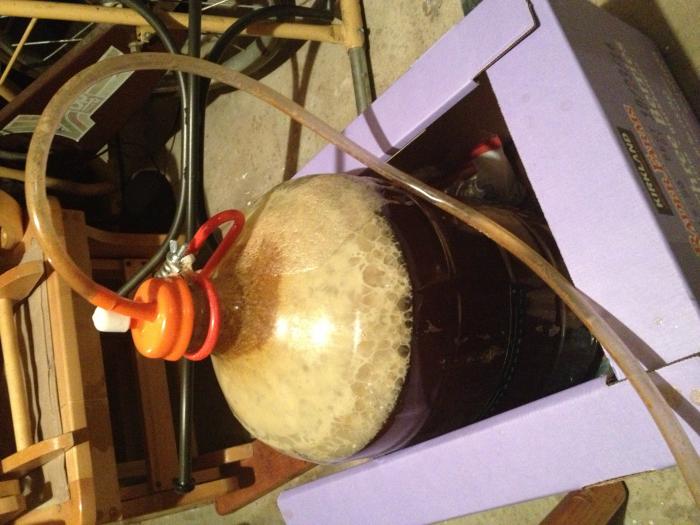

Hi guys Ive been reading a lot on here over the last few weeks. Ill start by saying I bought a kit a long time ago... Like 03/04, and then never touched it. My brother just got out of the military and moved back to CO and wanted to brew some beer. So we went down to the lhbs and picked up a Hefe kit. So Saturday was my first go at it. For the most part everything went ok. Biggest problem I ran into was my brew pot is too small. Its 16 quart. I had to top it off in the carboy, which I know is a big risk of infection. The instruction in my old kit said to do this, so Im hoping it all works out.

-Steeped grains @155 degrees for 45 min (directions said 30-45)

-Added hopps @ boil and @ 50 min

-Used an ice bath and a wort chiller I built. Got down to 75 degrees in about 20 min.

-My OG came out to 1.050

-Steeped grains @155 degrees for 45 min (directions said 30-45)

-Added hopps @ boil and @ 50 min

-Used an ice bath and a wort chiller I built. Got down to 75 degrees in about 20 min.

-My OG came out to 1.050

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)