Last year, I "upgraded" my mash tun from a basic cooler to a Chapman 10 Gallon mash tun and since then I get less than 50% efficiency.

I have been all-grain brewing since the 1990s, but I cannot figure out why the efficiency frankly sucks.

I have done about 10 brews with stirring more/less stirring, different saccharification temps, different recipes and improvement in final gravity.

No off tastes and good clean beer.

On BeerSmith I have lowered my efficiency to 65% and I'm getting 65% of that.

Set up:

Ferroday Malt Crusher

Chapman 10 Gallon Mash tun with false bottom

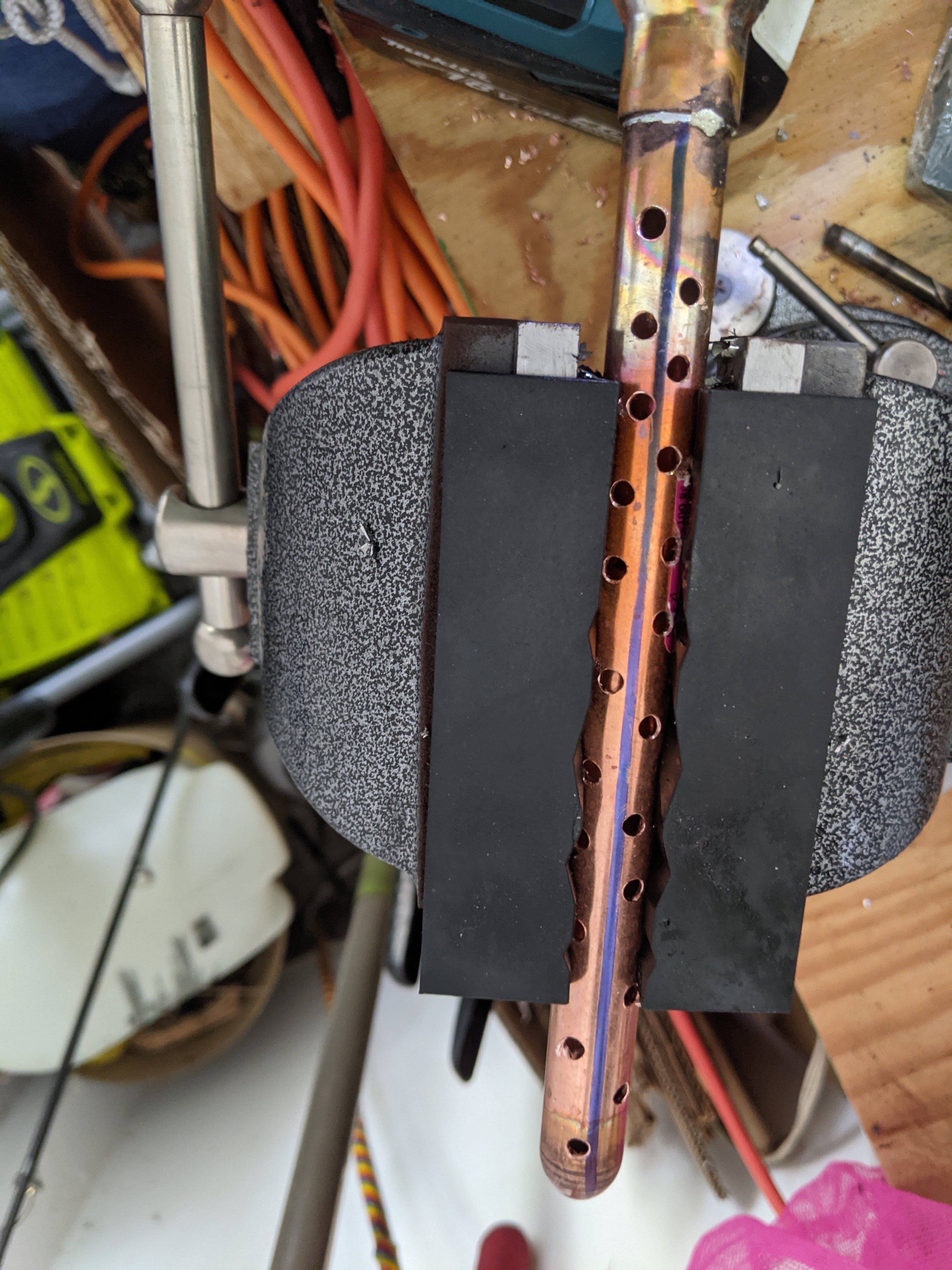

RIMs Rocket

Digital temperature controller for RIMs

Cheap hot water pump

20+ year old 10 gallon kettle

Copper coil heat exchange

Various 5-8 gallon carboys and fermentation buckets.

Today, I mashed in a high gravity Hefeweizen with Starfruit added in the primary.

To help eliminate grain milling as a variable, today I used pre-crushed grains directly from Marris Otter I obatined from a professional brewery. (Minimal difference in gravity from milling at home)

Mash tun with RIMs heating. Pump moves ~3 gallons a minute.

The mash after 30 minutes at 148 had a pH of mid 5s and SG of 1.085

The first wash 15 minutes at 152 had a pH of mid 5s and SG of 1.038

The sparge final temp 160 and a pH of mid 6s and SG of 1.033

Post boil gravity is 1.066.

Target SG: 1.0.98 @ 65% efficiency.

When I add water, I always let the grains settle to avoid dough balls.

I keep the thermometer near the top of the grains, near the hot water RIMs to avoid scotching.

There is good steady slow through the RIMs. The canister is clean at the end, so not sucking up grains.

During the entire process, I stir 2-3 times, let it settle, then resume the RIMs.

Same well water I have used for a decade.

Same volumes, same pot, same fermentors,....

Only difference is re-circulation vs stagnant cooler.

My best guess is perhaps since I tend to brew imperials, barley wines, and other gravity beer. The mash tun simply does not have the capacity, but I do not see why 2-3 washes with better temperature control and re-circulation should not achieve the same goal as dumping hot water in a cooler and letting it sit stagnant.

At this point,... I cannot figure it out. So any ideas?

I have been all-grain brewing since the 1990s, but I cannot figure out why the efficiency frankly sucks.

I have done about 10 brews with stirring more/less stirring, different saccharification temps, different recipes and improvement in final gravity.

No off tastes and good clean beer.

On BeerSmith I have lowered my efficiency to 65% and I'm getting 65% of that.

Set up:

Ferroday Malt Crusher

Chapman 10 Gallon Mash tun with false bottom

RIMs Rocket

Digital temperature controller for RIMs

Cheap hot water pump

20+ year old 10 gallon kettle

Copper coil heat exchange

Various 5-8 gallon carboys and fermentation buckets.

Today, I mashed in a high gravity Hefeweizen with Starfruit added in the primary.

To help eliminate grain milling as a variable, today I used pre-crushed grains directly from Marris Otter I obatined from a professional brewery. (Minimal difference in gravity from milling at home)

Mash tun with RIMs heating. Pump moves ~3 gallons a minute.

The mash after 30 minutes at 148 had a pH of mid 5s and SG of 1.085

The first wash 15 minutes at 152 had a pH of mid 5s and SG of 1.038

The sparge final temp 160 and a pH of mid 6s and SG of 1.033

Post boil gravity is 1.066.

Target SG: 1.0.98 @ 65% efficiency.

When I add water, I always let the grains settle to avoid dough balls.

I keep the thermometer near the top of the grains, near the hot water RIMs to avoid scotching.

There is good steady slow through the RIMs. The canister is clean at the end, so not sucking up grains.

During the entire process, I stir 2-3 times, let it settle, then resume the RIMs.

Same well water I have used for a decade.

Same volumes, same pot, same fermentors,....

Only difference is re-circulation vs stagnant cooler.

My best guess is perhaps since I tend to brew imperials, barley wines, and other gravity beer. The mash tun simply does not have the capacity, but I do not see why 2-3 washes with better temperature control and re-circulation should not achieve the same goal as dumping hot water in a cooler and letting it sit stagnant.

At this point,... I cannot figure it out. So any ideas?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)