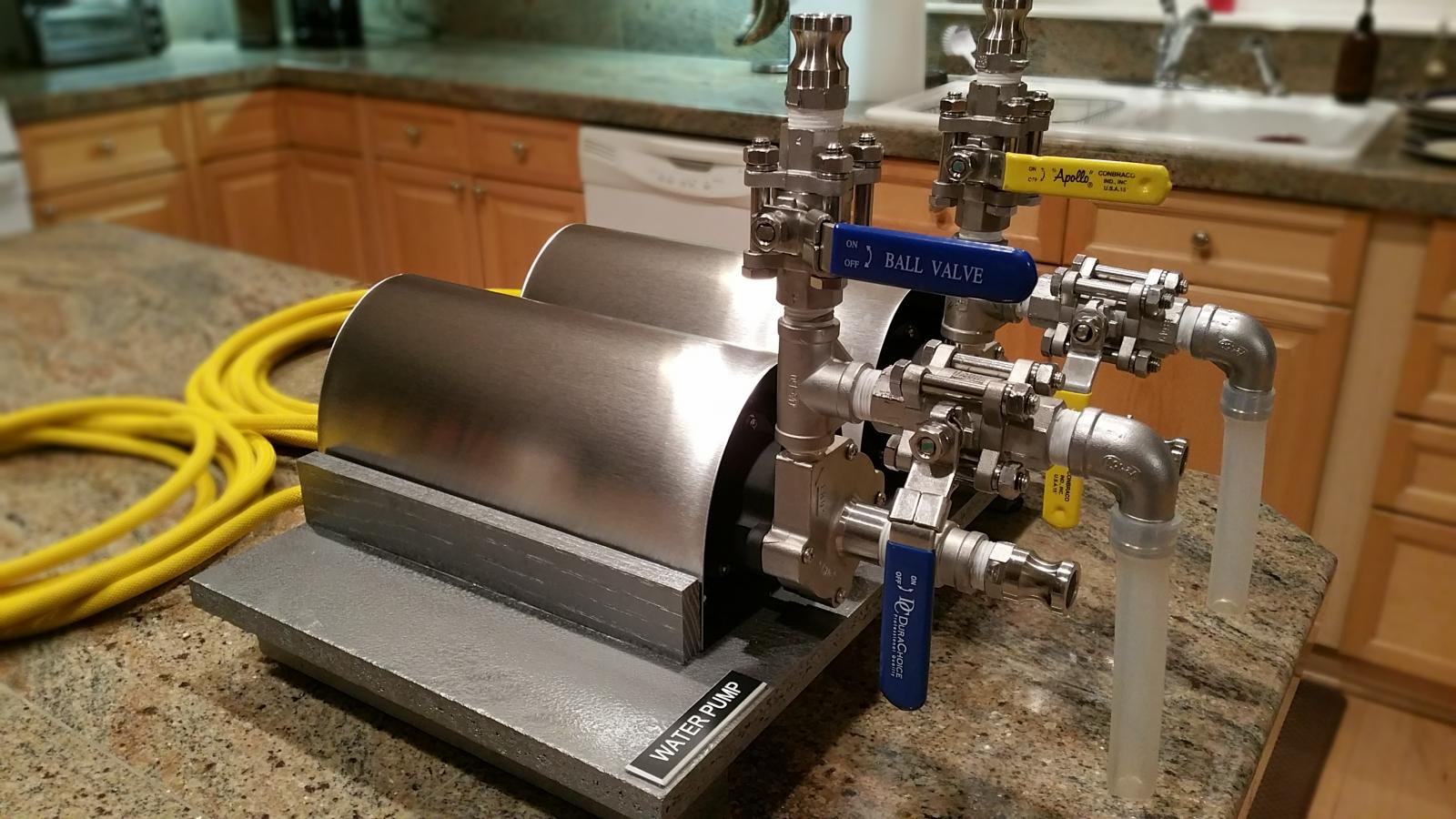

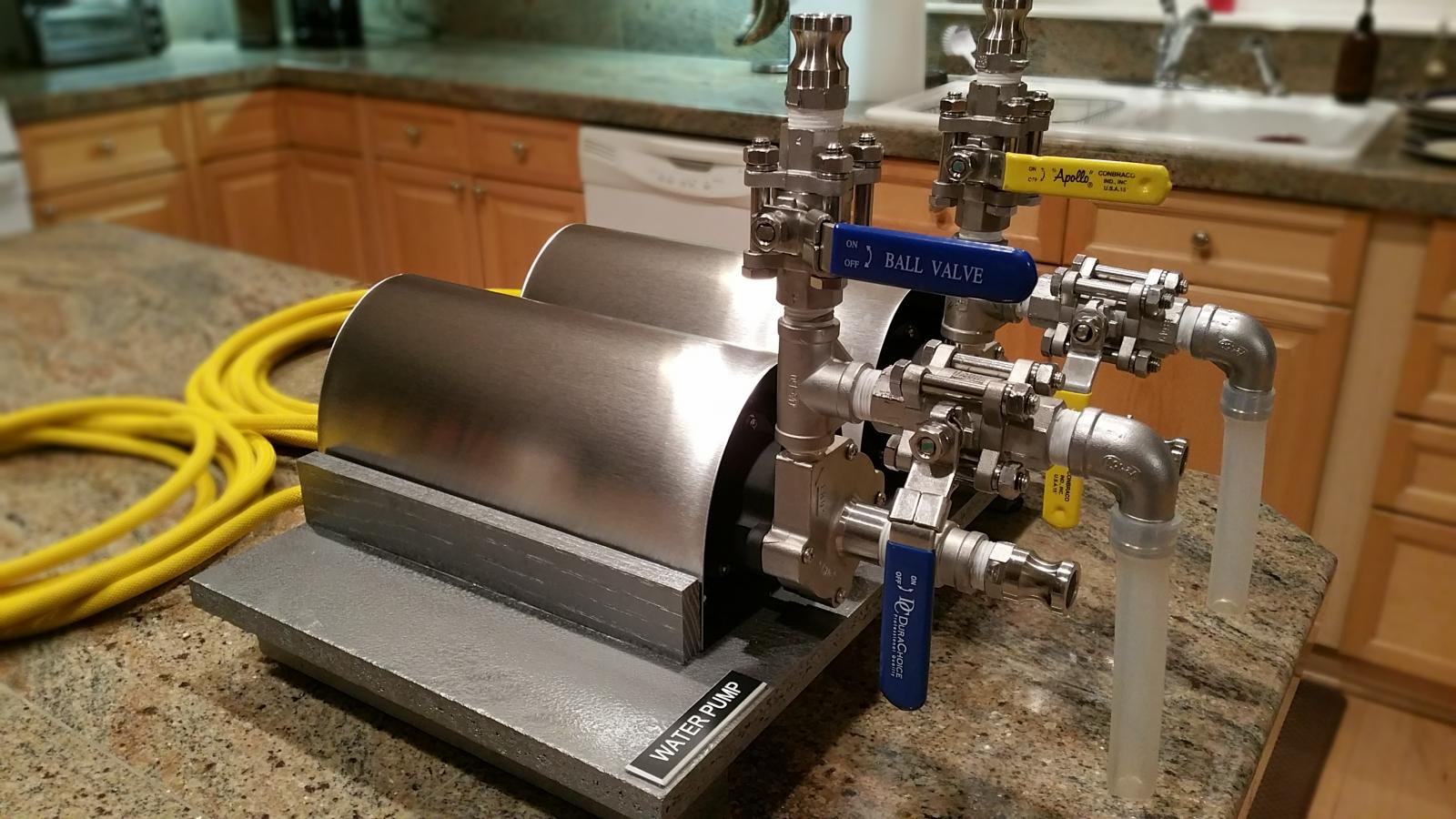

Hi all! New to the forum... Been working on this system for the last few years and was finally able to pull off my first batch this weekend. A few things that need "tweaked" but overall good to go! Had an issue with the pumps overheating but was able to cool them with a fan. Snapped a quick video to share. The goal is to eventually brew in the basement once I get the right setup with power and plumbing. Until then its outdoors. Looking forward to many more brew days!

Uploaded a few more photos...

Cheers! https://youtu.be/NQwYqHx4PZk

View attachment 1441771729144.jpg

Uploaded a few more photos...

Cheers! https://youtu.be/NQwYqHx4PZk

View attachment 1441771729144.jpg

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)