Bigarcherynut

Well-Known Member

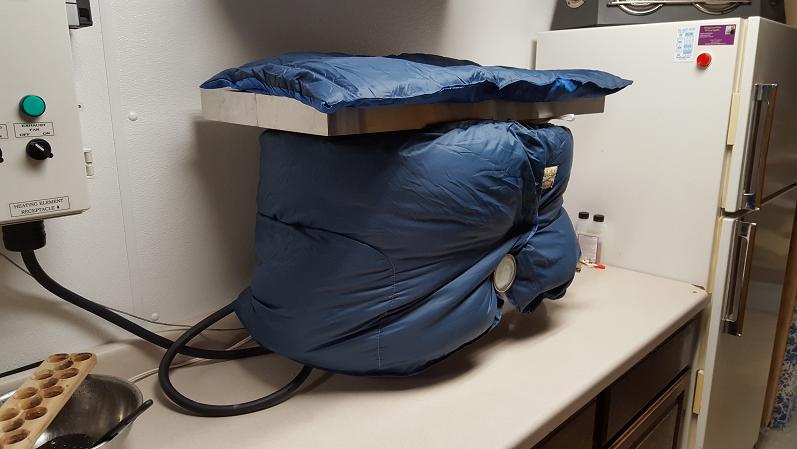

Well about a month ago I came across a portable whirlpool that the motor went out in and the manufacturer said was obsolete. It was heading to be recycled when I came upon it. I decided to do the rebirth.

2 years ago my daughter bought me a Mr. Beer for Christmas. Being a beer drinker was excited to try this new hobby out. Wasn't long and I was doing 5 gallon batches. I've had great success and have done a variety of styles. Never thought I could stray from my Miller Highlife. Lol

While I did a thread about my find, wilserbrewer, a member on the forum mentioned it looked perfect for an e-kettle. Unknown to me at the time what that was I started my research on it. I had done a partial grain clone of a Black Butte Porter and that got my interest in all grain. I did a thread in regards to being ready to go all grain I didn't have the equipment. The research began and once I read about the e-kettle I came across BIAB. Wow, sounded great to me so the project began.

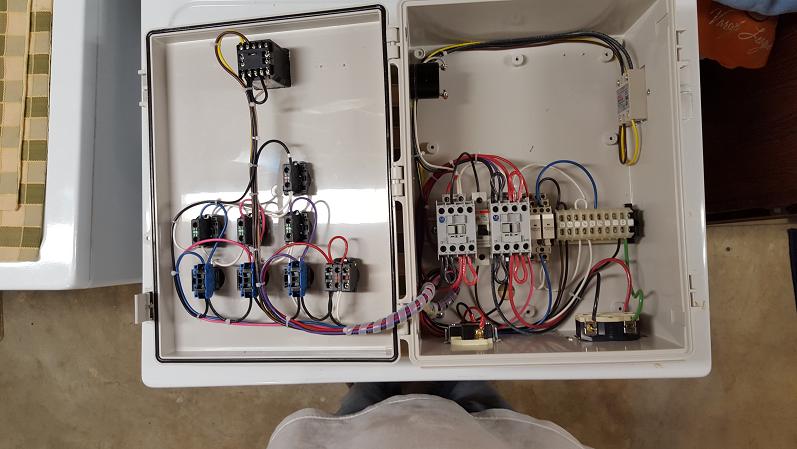

Not only did the e-kettle excite me being an electrician but I could move my brewing from our kitchen and make my wife a little happy. The basement was perfect. I had an old counter area with cabinets above we use for can goods. I removed the cabinets and installed fiberglass paneling. Water is 3' away and my daughter had found me a used frig for converting into my brewing frig.

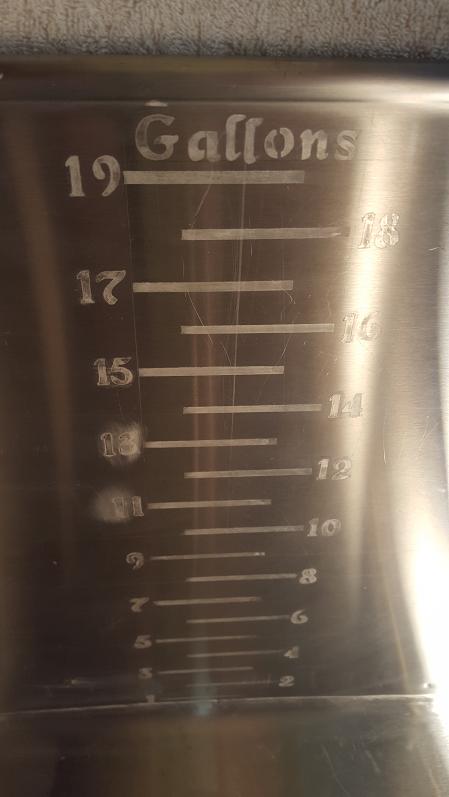

Here are some pics of my project.

Here's the kettle as it was just before hitting the recycling bin.

2 years ago my daughter bought me a Mr. Beer for Christmas. Being a beer drinker was excited to try this new hobby out. Wasn't long and I was doing 5 gallon batches. I've had great success and have done a variety of styles. Never thought I could stray from my Miller Highlife. Lol

While I did a thread about my find, wilserbrewer, a member on the forum mentioned it looked perfect for an e-kettle. Unknown to me at the time what that was I started my research on it. I had done a partial grain clone of a Black Butte Porter and that got my interest in all grain. I did a thread in regards to being ready to go all grain I didn't have the equipment. The research began and once I read about the e-kettle I came across BIAB. Wow, sounded great to me so the project began.

Not only did the e-kettle excite me being an electrician but I could move my brewing from our kitchen and make my wife a little happy. The basement was perfect. I had an old counter area with cabinets above we use for can goods. I removed the cabinets and installed fiberglass paneling. Water is 3' away and my daughter had found me a used frig for converting into my brewing frig.

Here are some pics of my project.

Here's the kettle as it was just before hitting the recycling bin.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)