gavinr

Active Member

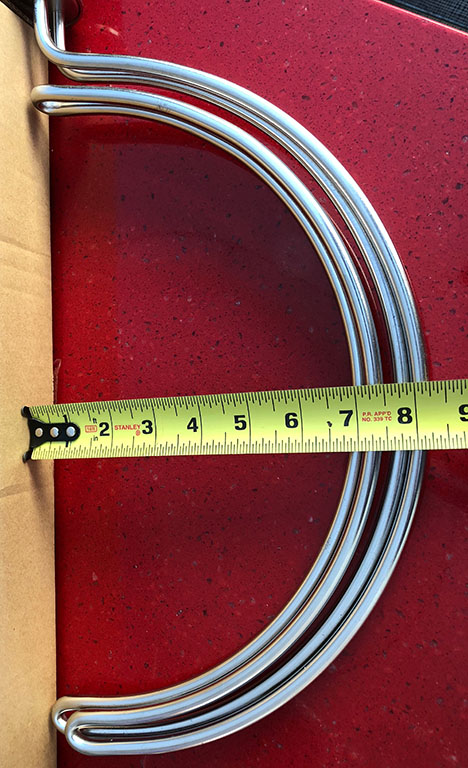

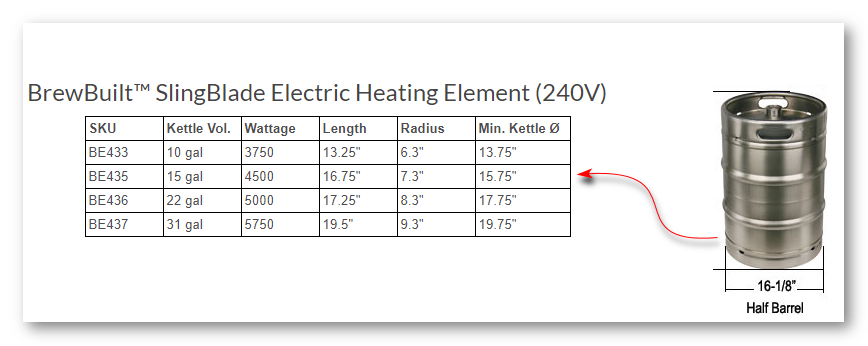

Anyone used these yet? Looks like they use the standard 1.5 TC ferrule fitting. Huge benefit - they will not interfere with the trub cone after whirlpool, like the ripple ones do. Slightly lower wattage (4500w) for my 15 gal kettle, but I run my current 5.5K element at 55% during the boil.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)