hatrickwah

Sponsor

Hey all, had at least one request that I be sure to share my latest project with all. That, and I haven't seen to much like it so on the premise of being different here we roll.

I've been brewing in Wyoming for about 3 years, but this past month my family was transferred to Texas. So far so good on the home and work front, but it is definitely getting to be time to brew. You know it is bad when SWMBO is asking when I plan to brew my first Texas brew.

My problems that didn't exist in Wyoming all sum up to one issue HEAT. Tap water is to hot to knock out and ambient temperature is to warm for yeast to do their best work, and on top of that, no basement to avoid the heat.

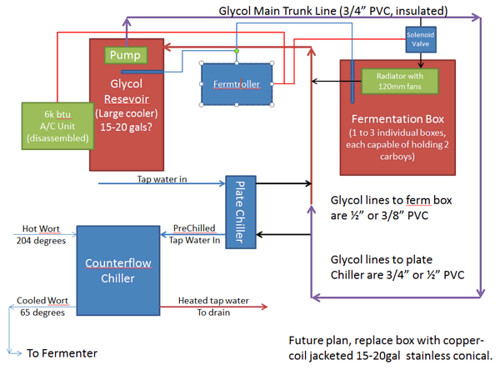

My solution is this, I'll share the details of my plan as I go later:

Since today was my first day to tackle this project on the fabrication side, I'll wait until tomorrow with pics. But the sum of the story, so far I have demoed some plastic, moved an a/c coil and set it in a 54qt cooler. I have begun to build my work bench/brew area, and I still plan to brew my first batch tomorrow afternoon (using my currently unused keezer to maintain temps for now).

I've been brewing in Wyoming for about 3 years, but this past month my family was transferred to Texas. So far so good on the home and work front, but it is definitely getting to be time to brew. You know it is bad when SWMBO is asking when I plan to brew my first Texas brew.

My problems that didn't exist in Wyoming all sum up to one issue HEAT. Tap water is to hot to knock out and ambient temperature is to warm for yeast to do their best work, and on top of that, no basement to avoid the heat.

My solution is this, I'll share the details of my plan as I go later:

- Obtain a Brewtroller board, new/old not so important since we are going for basic operation. [Check, found a used one, thanks]

- Build a glycol unit controlled via a channel on the Fermtroller setup.

- Build a box (or few) to control the temperature of a somewhat smaller space, and use Fermtroller again to maintain the temperatures in the box.

- Find a small to medium size plate chiller adequate enough to take my tap water from what ever it is now (~75-80 degrees) and knock the tap down to minimum of 70, and maybe even lager 50s if I so desired. Before the tap water enters my CFC.

- Depending on efficiency, add a 3rd box/cooler for keeping kegs cool while waiting to be tapped.

- FAR OFF FUTURE - CONICALS.

Since today was my first day to tackle this project on the fabrication side, I'll wait until tomorrow with pics. But the sum of the story, so far I have demoed some plastic, moved an a/c coil and set it in a 54qt cooler. I have begun to build my work bench/brew area, and I still plan to brew my first batch tomorrow afternoon (using my currently unused keezer to maintain temps for now).

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)