Hey all,

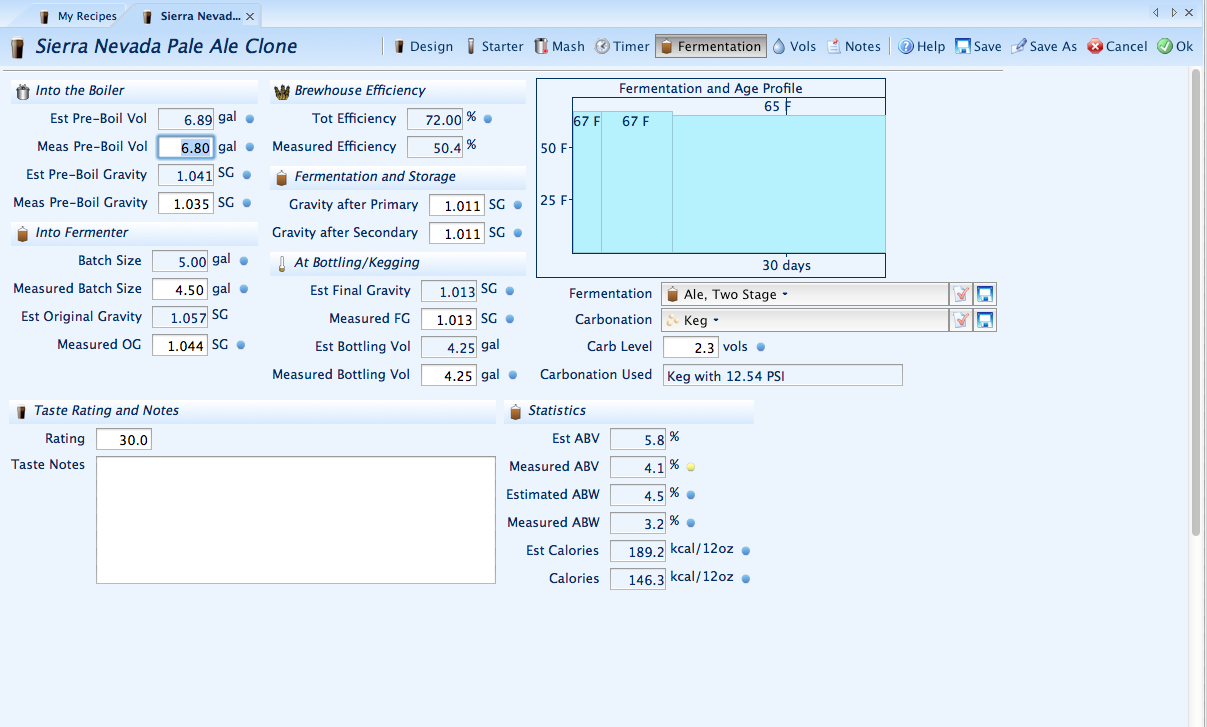

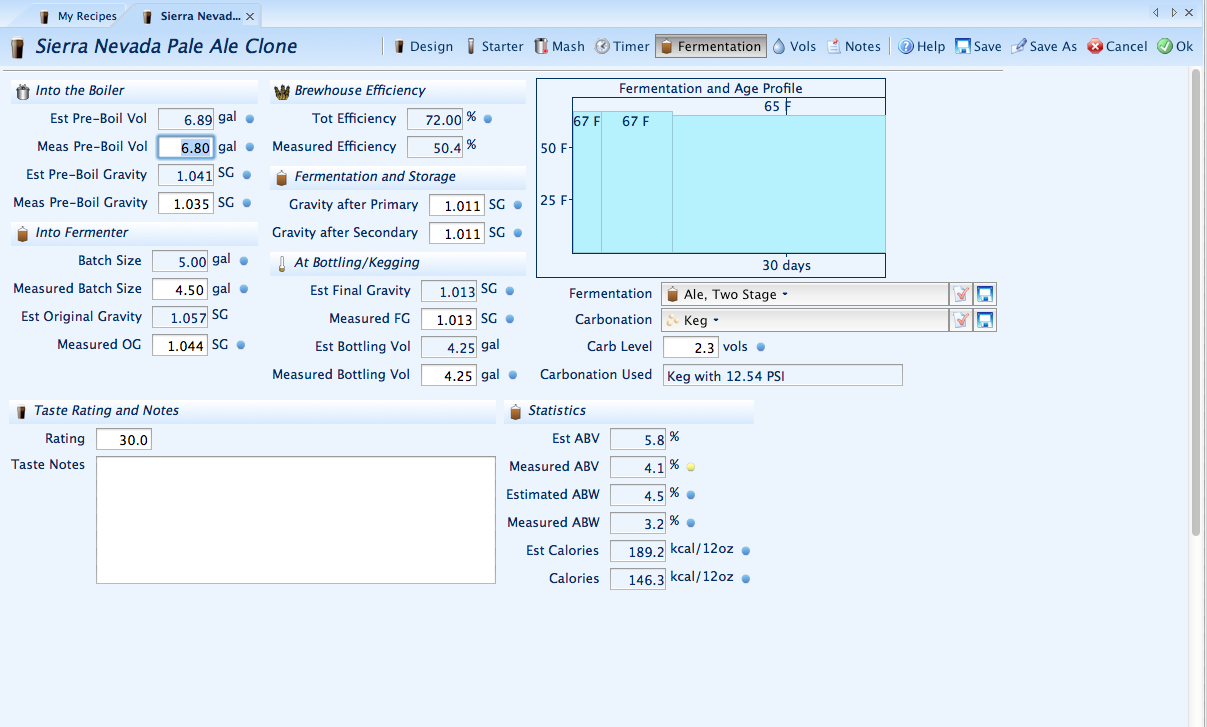

I am a new brewer and new to the forums as well. I have done some research online to try and find ways to increase my efficiency. I just finished my fourth brew today and had another disappointing brewhouse efficiency of 50%. My previous brews have all had around the same efficiency and I was looking for helpful advice. I have included screen shots of my recipe and calculations from beersmith.

The recipe is a Sierra Nevada Clone that I got from this link: http://byo.com/recipe-exchange/item/3025-sierra-nevada-pale-ale-clone

Some things I read is to stir more and that pH could be an issue. I appreciate any additional help or feedback on improving my efficiency and brewing techniques. (Also, FYI I forgot to add my pH 5.2 stabilizer to this brew)

I also seem to have trouble reaching the a final fermentation volume of 5 gal and typically have 4.5-4.7 gallons.

Again, thank you for any help you can provide and I am excited to be a part of the home brew talk forum community.

I am a new brewer and new to the forums as well. I have done some research online to try and find ways to increase my efficiency. I just finished my fourth brew today and had another disappointing brewhouse efficiency of 50%. My previous brews have all had around the same efficiency and I was looking for helpful advice. I have included screen shots of my recipe and calculations from beersmith.

The recipe is a Sierra Nevada Clone that I got from this link: http://byo.com/recipe-exchange/item/3025-sierra-nevada-pale-ale-clone

Some things I read is to stir more and that pH could be an issue. I appreciate any additional help or feedback on improving my efficiency and brewing techniques. (Also, FYI I forgot to add my pH 5.2 stabilizer to this brew)

I also seem to have trouble reaching the a final fermentation volume of 5 gal and typically have 4.5-4.7 gallons.

Again, thank you for any help you can provide and I am excited to be a part of the home brew talk forum community.