Experience: 8th batch total. 4th all-grain.

Changes from past batches:

-Trying some water treatment for the first time. I learned through input here that my local water supply coming out of the tap is very close to RO water, so, I'm effectively treating it as such. One of the "for newbies" articles I found on water treatment that I believe is referenced here suggested 2 tsp of gypsum and .5tsp baking soda per five gallons. So I added that to my mash and sparge water supply, in addition to my quarter tablet of campden for chlorine.

Issues unique to this batch:

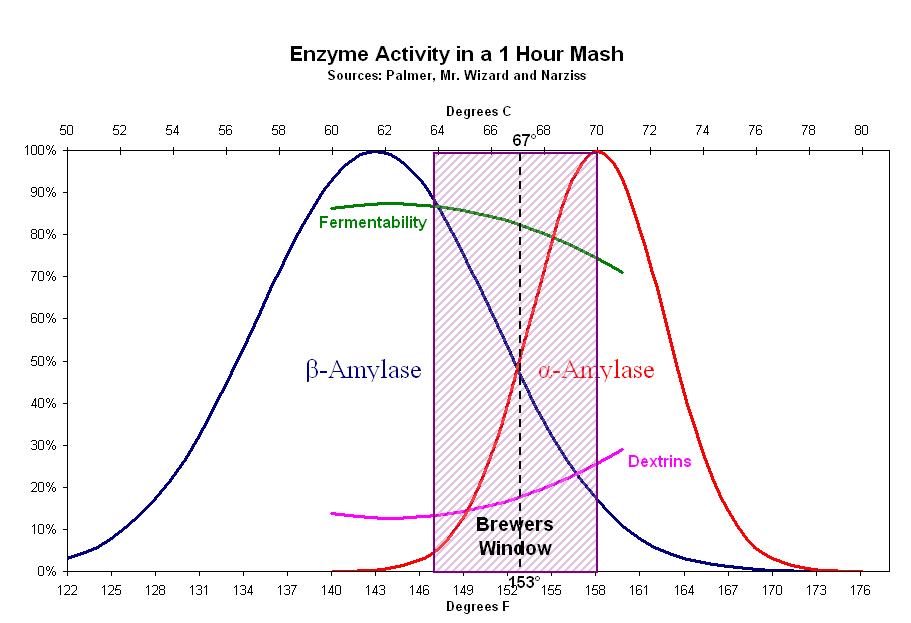

- First off, I missed my mash temp. This has not happened before, so I don't know why. I use a spreadsheet made by a youtube guy that uses similar equipment as I do, I've taken notes as well, and in the past I've had no issues getting very close to mash temp usually between bang-on and 1.5 degrees high. This time I missed it by 4 degrees low. Recipe called for 149, I started at 145. Yes, I preheated the mashtun same as before. After a very quick google I boiled up a gallon of water and started adding it until I got up to 150. This was about 15 minutes after mash in. How screwed am I on the mash?

-Efficiency was not good. With the exception of one stuck sparge that went sideways, my normal sparges with pre-crushed grain have been over 80%. This one is showing just under 68% on the calculators. Could this be due to temp or water additions? I didn't end up adding any extra sugar to the boil. The original target was for 7% ABV; I think I'm on track for 6%, so hopefully I just a have a decent beer that is a little lighter than the recipe intended.

-Fermentation (2 days in now): This was my second batch using liquid yeast with a starter. The first one definitely started quicker than I have seen when direct-pitching dry yeast, but this one was next level. 12 hours in, I had an inch of krausen. 24 hours in, it started blowing off, and I switched to the blowoff tube from my starter kit (glad they included that). I've got 5.3ish gallons in a 6.5gal big mouth bubbler. The most krausen I've got before is 1, maybe 1.5". Not close to a blowoff. The OG of this one was 1.058; not even the biggest beer I've done so far. The krausen bubbles just seem to not want to pop as easily. It is not the most bubbly one I've had either, at least as of this morning, last time I looked at about 36 hours in. Could this be due to water additions, or some other factors? Grain bill doesn't look all that different from others I've brewed, and I've used this same yeast, and never came close to a blowoff before.

Thanks for any thoughts.

Changes from past batches:

-Trying some water treatment for the first time. I learned through input here that my local water supply coming out of the tap is very close to RO water, so, I'm effectively treating it as such. One of the "for newbies" articles I found on water treatment that I believe is referenced here suggested 2 tsp of gypsum and .5tsp baking soda per five gallons. So I added that to my mash and sparge water supply, in addition to my quarter tablet of campden for chlorine.

Issues unique to this batch:

- First off, I missed my mash temp. This has not happened before, so I don't know why. I use a spreadsheet made by a youtube guy that uses similar equipment as I do, I've taken notes as well, and in the past I've had no issues getting very close to mash temp usually between bang-on and 1.5 degrees high. This time I missed it by 4 degrees low. Recipe called for 149, I started at 145. Yes, I preheated the mashtun same as before. After a very quick google I boiled up a gallon of water and started adding it until I got up to 150. This was about 15 minutes after mash in. How screwed am I on the mash?

-Efficiency was not good. With the exception of one stuck sparge that went sideways, my normal sparges with pre-crushed grain have been over 80%. This one is showing just under 68% on the calculators. Could this be due to temp or water additions? I didn't end up adding any extra sugar to the boil. The original target was for 7% ABV; I think I'm on track for 6%, so hopefully I just a have a decent beer that is a little lighter than the recipe intended.

-Fermentation (2 days in now): This was my second batch using liquid yeast with a starter. The first one definitely started quicker than I have seen when direct-pitching dry yeast, but this one was next level. 12 hours in, I had an inch of krausen. 24 hours in, it started blowing off, and I switched to the blowoff tube from my starter kit (glad they included that). I've got 5.3ish gallons in a 6.5gal big mouth bubbler. The most krausen I've got before is 1, maybe 1.5". Not close to a blowoff. The OG of this one was 1.058; not even the biggest beer I've done so far. The krausen bubbles just seem to not want to pop as easily. It is not the most bubbly one I've had either, at least as of this morning, last time I looked at about 36 hours in. Could this be due to water additions, or some other factors? Grain bill doesn't look all that different from others I've brewed, and I've used this same yeast, and never came close to a blowoff before.

Thanks for any thoughts.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)