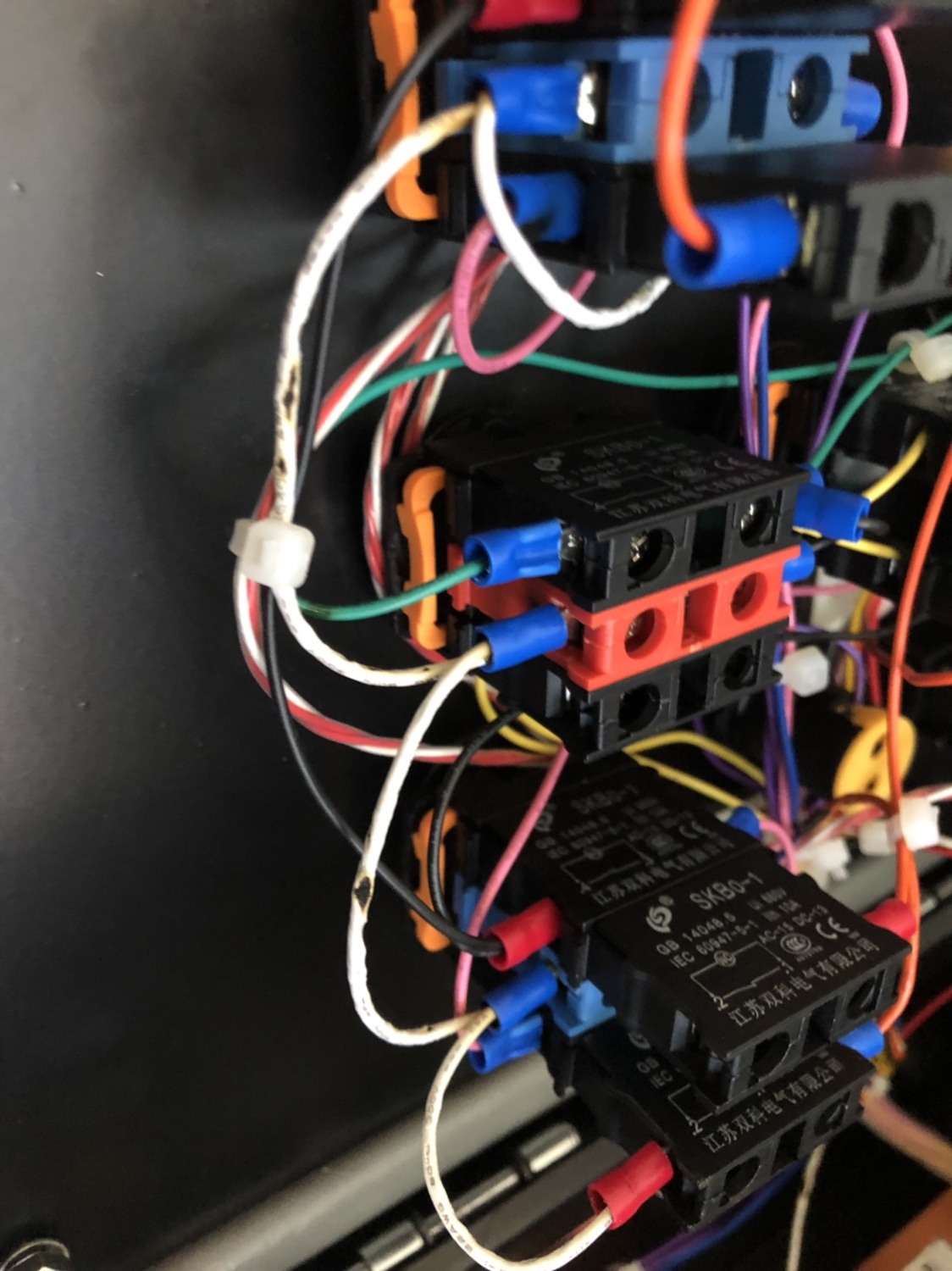

I just plugged in my Auber Brew Buddy panel for the first time to test it and the wire along the entire neutral circuit fried instantly before the GFCI breaker in my panel could even trip.

I don't even know where to start with trying to figure out what happened.

Is everything connected to that neutral line fried now? Did I just burn up $1000 panel?

Any advice appreciated.

I don't even know where to start with trying to figure out what happened.

Is everything connected to that neutral line fried now? Did I just burn up $1000 panel?

Any advice appreciated.