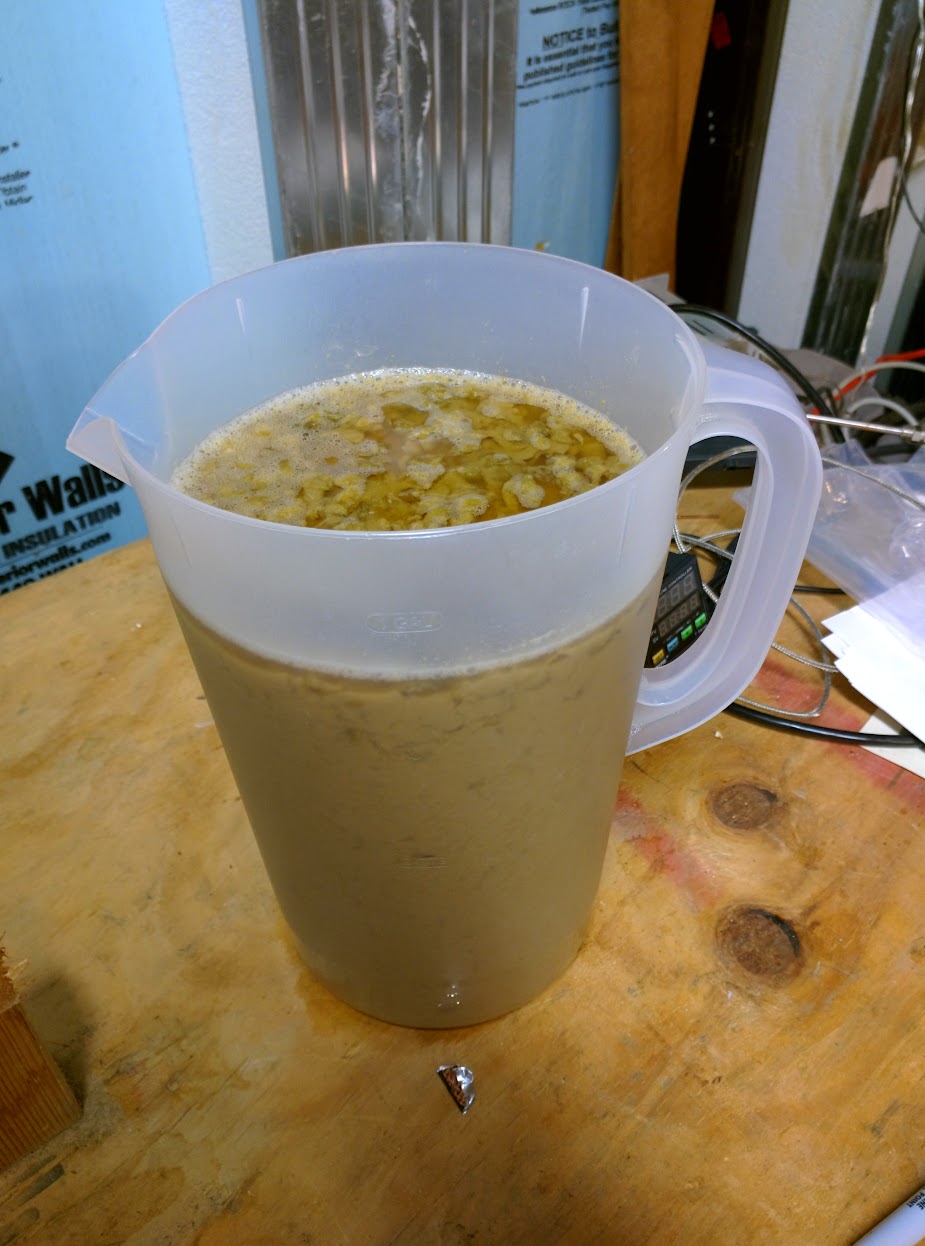

I have an electric biab setup and as of yesterday have brewed 3 batches in it. I am finding that I have excessive trub or sediment in the kettle or transfered over to the primary fermentor. I have attached pics of this. The first batch was a extract batch and not a biab so that one did not have the issue, but the next two did. The first biab batch only yielded 2.6 gallons into the keg when done, due to the loses from a 5 gallon batch size. This was started with 8.5 gallons water to start the batch. I also had a bit of an error with my boil off rate with this one. Despite this the beer came out great. So onto the batch yeserday, I corrected the boil off rate in beersmith and started with 9.2 gallons this time and this workedout about right with about 5.2 gallons of wort after the boil, but I was only able to get 4 gallons because of the sediment. I had abut a gallon of heavy sediment and looks like i have about 1/2 inch or so settled out in the carboy after letting it sit over night, so an other short batch. Could it be the bags I am using are too corse. The first bag I used was a grain bag from my local home brew store. The bag yesterday came from morebeer.com this one https://www.morebeer.com/products/bag-29-brew-biab.html it said it is for biab so I am at a loss for what is going on here can anyone help?

[/IMG][/IMG]

[/IMG][/IMG]

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)