jcmcdowell

Well-Known Member

Hi Guys,

NOTE- I have 3 phase power

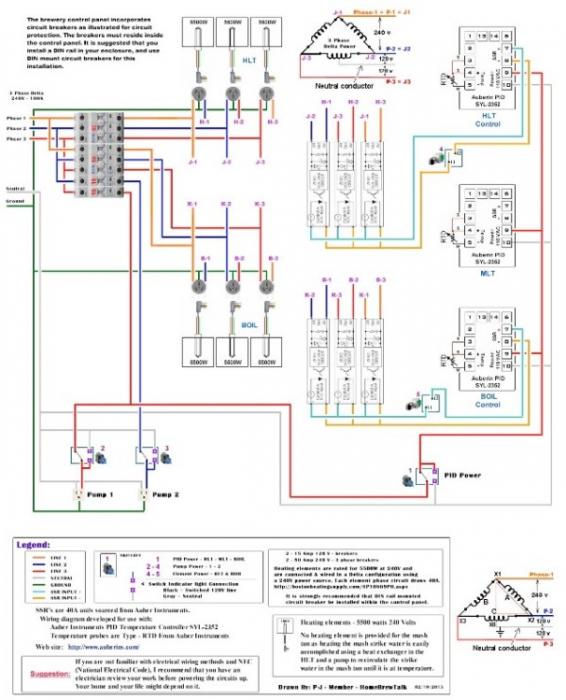

I am building a variation of a single vessel brewery/braumeister with a 55 gal SS drum as the MT and BK. I want to use the Auberins PID SWA-24X1 PID/Timer controller and 3-regular 240v 5500w heating elements.

I will have one pump.

I'm trying to keep the controller as simple and cheap to build as I can.

I'm thinking I need-

ON/OFF illuminated button

PID/TIMER (wired 240v?)

Alarm light/buzzer

reset button for timer

Element on/off switch (one for all 3?) (illuminated)- can it be wired for one contactor?

Pump on/off switch (illuminated) (my pump is 240v)

enclosure (like the 8x10 pre cut one from Auberins)

3 SSR's (5500w at 208v is less than 30 amps max draw)

3 heat sinks (3-40amp or 1 big heat sink?)

1- temp sensor probe with 1.5" tri clover

I have 200amps 3 phase power. I was planning on using a triple 30amp breaker and 3-208v lines to the elements. All the elements would be on/off at the same time to balance the load. The 240v pump and PID another 20amp breaker?

I have on hand the pump, a bunch of 1.5" tri clover fittings and ferrules, the male and female 30amp sockets, connectors for sensors, valves, etc...

I just need to pull the trigger on the Auberins order.

I've seen diagrams for 2-5500w elements but not 3. I have the 3 phase but I'd like to essentially plan on using the 4 wire as separate 208v lines to standard 240v elements. I know I won't get the full 5500 watts this way, but three elements should be plenty.

References, help, or ideas?

Thanks

JC McDowell

current keggle system

NOTE- I have 3 phase power

I am building a variation of a single vessel brewery/braumeister with a 55 gal SS drum as the MT and BK. I want to use the Auberins PID SWA-24X1 PID/Timer controller and 3-regular 240v 5500w heating elements.

I will have one pump.

I'm trying to keep the controller as simple and cheap to build as I can.

I'm thinking I need-

ON/OFF illuminated button

PID/TIMER (wired 240v?)

Alarm light/buzzer

reset button for timer

Element on/off switch (one for all 3?) (illuminated)- can it be wired for one contactor?

Pump on/off switch (illuminated) (my pump is 240v)

enclosure (like the 8x10 pre cut one from Auberins)

3 SSR's (5500w at 208v is less than 30 amps max draw)

3 heat sinks (3-40amp or 1 big heat sink?)

1- temp sensor probe with 1.5" tri clover

I have 200amps 3 phase power. I was planning on using a triple 30amp breaker and 3-208v lines to the elements. All the elements would be on/off at the same time to balance the load. The 240v pump and PID another 20amp breaker?

I have on hand the pump, a bunch of 1.5" tri clover fittings and ferrules, the male and female 30amp sockets, connectors for sensors, valves, etc...

I just need to pull the trigger on the Auberins order.

I've seen diagrams for 2-5500w elements but not 3. I have the 3 phase but I'd like to essentially plan on using the 4 wire as separate 208v lines to standard 240v elements. I know I won't get the full 5500 watts this way, but three elements should be plenty.

References, help, or ideas?

Thanks

JC McDowell

current keggle system

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)