I will try and make this short and sweet, but it usually doesn't end up that way for me. If I use wrong terminology feel free to correct me as I have little experience around the internal components of electronics, and I want to do it right. The good news is my buddy knows a fair amount about it so he offered to help.

I am building a parts list for a control panel to run a single pump and 5500w element for a HERMS system. The boil kettle is still heated via propane.

I have tried to do my due diligence in reading through multiple posts as well as Kal's control panel build walk through.

So I am considering the following 3 options...

The basics and order the rest

http://www.ebrewsupply.com/1-pid-30a-biab-kit/

Has everything I need except it is not the PID I want

http://www.ebrewsupply.com/complete-30a-biab-kit/

Or Order everything individually

I will post my parts list, but note that I may not purchase everything from Auber. I will look for better prices if I can find them.

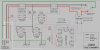

I believe this would be the appropriate design for what I want that I found in another thread created by doug293cz.

Parts List (Not going to have an element firing lamp)

Am I missing anything? (Even stuff you may consider minor but I left off!)

1- Enclosure with 40a heatsink

http://www.auberins.com/index.php?main_page=product_info&cPath=34&products_id=340

1 - EZboil

http://www.auberins.com/index.php?main_page=product_info&cPath=53&products_id=560

1- 40a SSR

http://www.auberins.com/index.php?main_page=product_info&cPath=2_30&products_id=30

1 - RTD Sensor with braided cable XLRCON Connector Female Panel Mount

http://www.auberins.com/index.php?main_page=product_info&cPath=20_15&products_id=261

2 - Push button switches (one for element, one for pump) (2NO or 1NO 1NC)

http://www.auberins.com/index.php?main_page=product_info&cPath=32&products_id=223

1 - Locking Inlet for Power Supply

http://www.auberins.com/index.php?main_page=product_info&cPath=7_43&products_id=460

1 - Socket for Element

http://www.auberins.com/index.php?main_page=product_info&cPath=7_43&products_id=410

1 - 120v Panel Mount Socket

http://www.auberins.com/index.php?main_page=product_info&cPath=34&products_id=274

1 - Plug for Element

http://www.auberins.com/index.php?main_page=product_info&cPath=7_43&products_id=411

2 - Contactors

http://www.auberins.com/index.php?main_page=product_info&cPath=2_31&products_id=129

1 - Main Power Switch

http://www.auberins.com/index.php?main_page=product_info&cPath=32&products_id=349

1 - 1amp fuse

http://www.ekmmetering.com/ekm-inline-fuse-holder-w-1-amp-fuse.html?gclid=CMuSgcXIkNMCFQgFaQodh50GAg

1 - 10amp fuse

https://www.amazon.com/dp/B003EEX5PQ/?tag=skimlinks_replacement-20

10ga Wire

16ga wire

20ga wire

Connectors

I am a little unclear on what block options I need for the main power switch.

What are the purple and turquoise wires going from the PID to the SSR?

Is a 50a GFI Spa panel the best way to go to run my 240 into?

Any help would be greatly appreciated!

I am building a parts list for a control panel to run a single pump and 5500w element for a HERMS system. The boil kettle is still heated via propane.

I have tried to do my due diligence in reading through multiple posts as well as Kal's control panel build walk through.

So I am considering the following 3 options...

The basics and order the rest

http://www.ebrewsupply.com/1-pid-30a-biab-kit/

Has everything I need except it is not the PID I want

http://www.ebrewsupply.com/complete-30a-biab-kit/

Or Order everything individually

I will post my parts list, but note that I may not purchase everything from Auber. I will look for better prices if I can find them.

I believe this would be the appropriate design for what I want that I found in another thread created by doug293cz.

Parts List (Not going to have an element firing lamp)

Am I missing anything? (Even stuff you may consider minor but I left off!)

1- Enclosure with 40a heatsink

http://www.auberins.com/index.php?main_page=product_info&cPath=34&products_id=340

1 - EZboil

http://www.auberins.com/index.php?main_page=product_info&cPath=53&products_id=560

1- 40a SSR

http://www.auberins.com/index.php?main_page=product_info&cPath=2_30&products_id=30

1 - RTD Sensor with braided cable XLRCON Connector Female Panel Mount

http://www.auberins.com/index.php?main_page=product_info&cPath=20_15&products_id=261

2 - Push button switches (one for element, one for pump) (2NO or 1NO 1NC)

http://www.auberins.com/index.php?main_page=product_info&cPath=32&products_id=223

1 - Locking Inlet for Power Supply

http://www.auberins.com/index.php?main_page=product_info&cPath=7_43&products_id=460

1 - Socket for Element

http://www.auberins.com/index.php?main_page=product_info&cPath=7_43&products_id=410

1 - 120v Panel Mount Socket

http://www.auberins.com/index.php?main_page=product_info&cPath=34&products_id=274

1 - Plug for Element

http://www.auberins.com/index.php?main_page=product_info&cPath=7_43&products_id=411

2 - Contactors

http://www.auberins.com/index.php?main_page=product_info&cPath=2_31&products_id=129

1 - Main Power Switch

http://www.auberins.com/index.php?main_page=product_info&cPath=32&products_id=349

1 - 1amp fuse

http://www.ekmmetering.com/ekm-inline-fuse-holder-w-1-amp-fuse.html?gclid=CMuSgcXIkNMCFQgFaQodh50GAg

1 - 10amp fuse

https://www.amazon.com/dp/B003EEX5PQ/?tag=skimlinks_replacement-20

10ga Wire

16ga wire

20ga wire

Connectors

I am a little unclear on what block options I need for the main power switch.

What are the purple and turquoise wires going from the PID to the SSR?

Is a 50a GFI Spa panel the best way to go to run my 240 into?

Any help would be greatly appreciated!

Last edited by a moderator: