Hi all, hopefully this is the correct place for this thread but i'm looking for help with my setup. Here is a little bit about it.

I have a 2 spout glycol tap on the bar with a truck line (something like this: http://www.beveragefactory.com/draftbeer/glycol-cooling/glycol-trunkline/bf_1441.shtml ) running ~40 feet back to a normal refrigerator with a freezer on top.

I have the beer delivery system planned and purchased ( 2 corny kegs, 1 sanke keg w/ quick connect, co2, etc) but i need help with pumping the glycol through the lines.

I'm wondering how I can hook up the pump to the trunk lines and what kind of reservoir i can use for the glycol itself. Should the reservoir be stored in the freezer or fridge part? I was thinking of just coiling a bunch of copper and filling it with the glycol. Would that be ok? Any help would be excellent!!

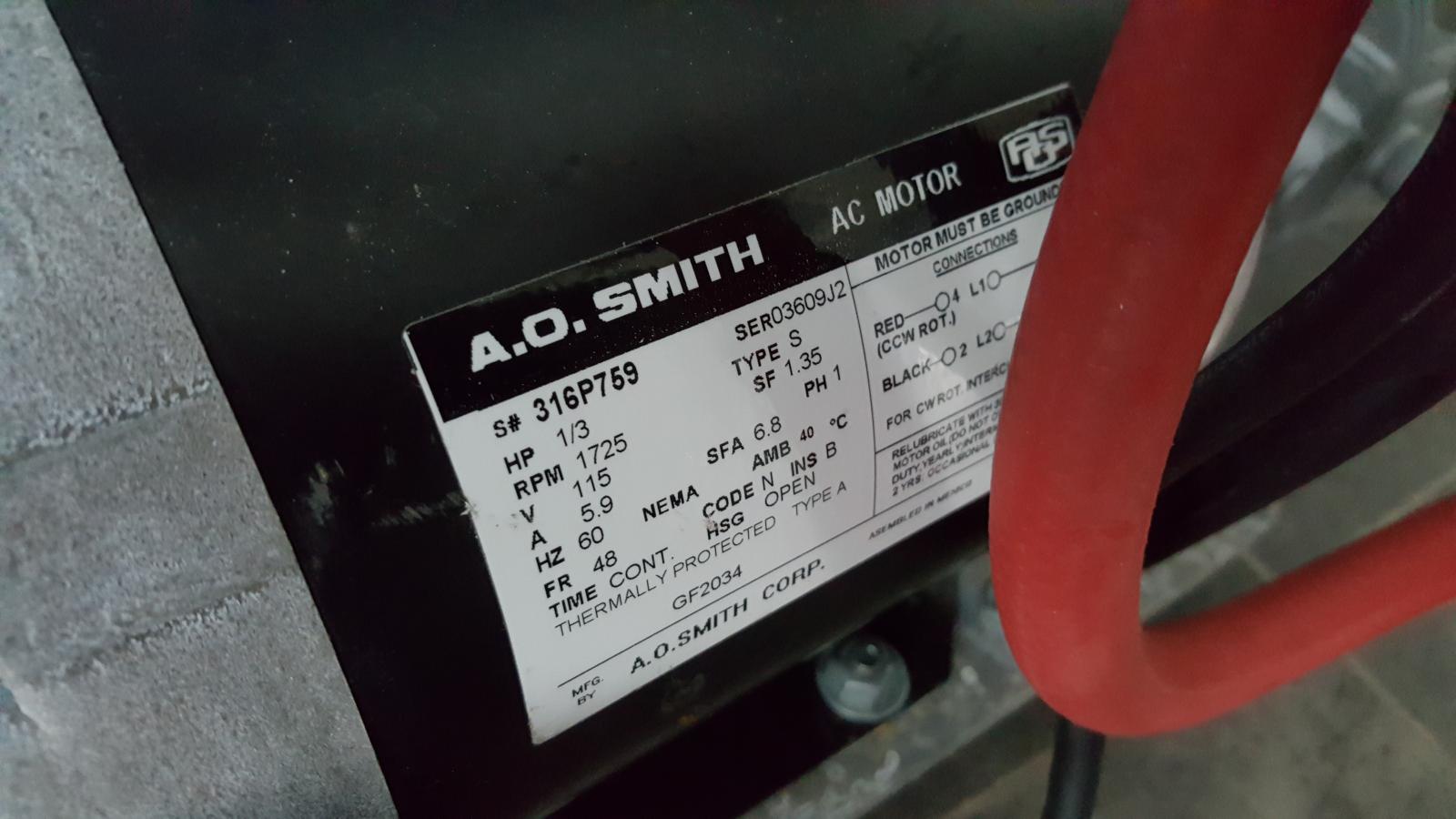

i've attached pics of the pump somebody gave me. it was from a friend of a friend that said it was used in a beer delivery system but i'm not sure of the details other than that.

Thanks!

I have a 2 spout glycol tap on the bar with a truck line (something like this: http://www.beveragefactory.com/draftbeer/glycol-cooling/glycol-trunkline/bf_1441.shtml ) running ~40 feet back to a normal refrigerator with a freezer on top.

I have the beer delivery system planned and purchased ( 2 corny kegs, 1 sanke keg w/ quick connect, co2, etc) but i need help with pumping the glycol through the lines.

I'm wondering how I can hook up the pump to the trunk lines and what kind of reservoir i can use for the glycol itself. Should the reservoir be stored in the freezer or fridge part? I was thinking of just coiling a bunch of copper and filling it with the glycol. Would that be ok? Any help would be excellent!!

i've attached pics of the pump somebody gave me. it was from a friend of a friend that said it was used in a beer delivery system but i'm not sure of the details other than that.

Thanks!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)