raouliii

Well-Known Member

Looks good. An elegant solution.

Oops... Your right... Fixed. Alcohol and a headache will do that.

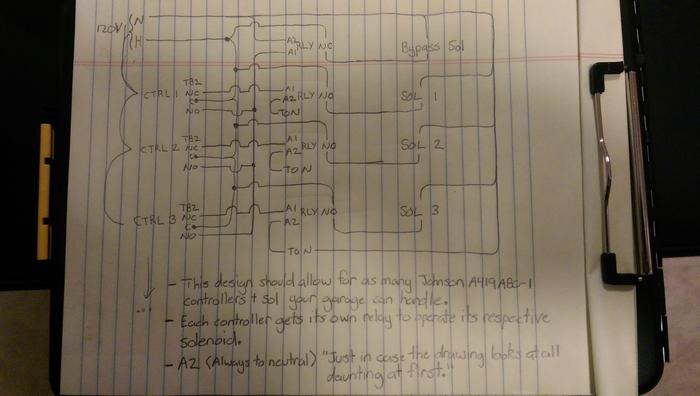

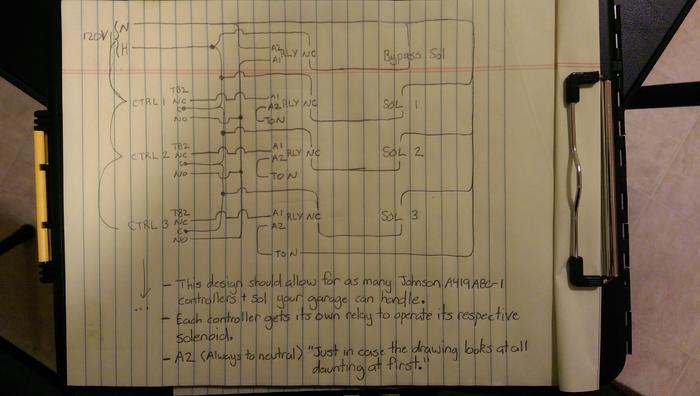

And if anyone is interested in nerding out on relay logic for some reason,

this thesis (preview unfortunately) by Claude Shannon

is a fun read. It would be rather dry and unremarkable.... had it not been submitted in 1940.

Page 59 gets eerie with proposing an "Electric adder to the base Two". (ahem...1940!)

Page 67 gets fun... with the introduction of a relay machine that calculates primes.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Ok wait I think I get it. There is no need for the second relay to be energized because it's basically just acting like a pass-through (I'm sure there is some other more technical term here!

And there is no need for main power - the first relay will pass that through when needed. I can take main power to the panel and just split it to the controllers (because I am sourcing that all from the panel). The rest will all be based on the state of the A419 relays back into my panel.

It's slowly sinking in!

No worries. I just like seeing what people do for possible ideas for myself.

Thats a hell of a little setup you have going there. How much were those jacketed conicals? Are they a PITA to clean?

Also do the toggle switches on the cover of your ctrl cabinet just bypass the temp controller, or does it completely shut off the controller?

Of course there are tons of ways to skin a cat. I like your set up for sure. I like your use of quick connectors for the electrical.

Finally, I have to say. Thats a heck of a chunk of change you have there. I can feel my wallet get thinner just thinking about setting something up like that.

Works - like a champ!

Congratulations!

Your setup looks very nice.

Cheers,

ClaudiusB