Hello - I am by no means an electrical/electronics guru. I do have some basic knowledge - and I have some experience with Arduino as well so I know how to solve my problem using Arduino. But I'm hoping I can solve it without it. Here's what I'm doing:

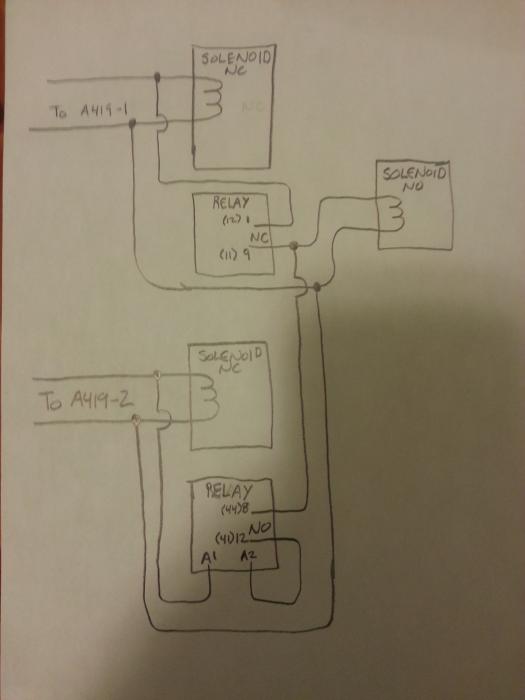

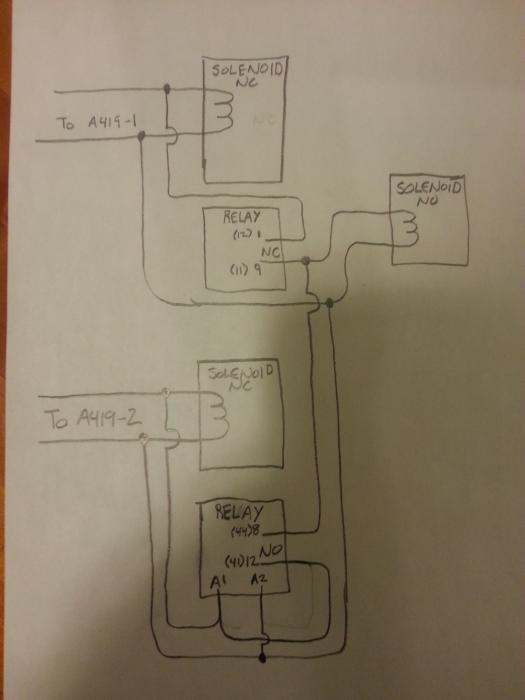

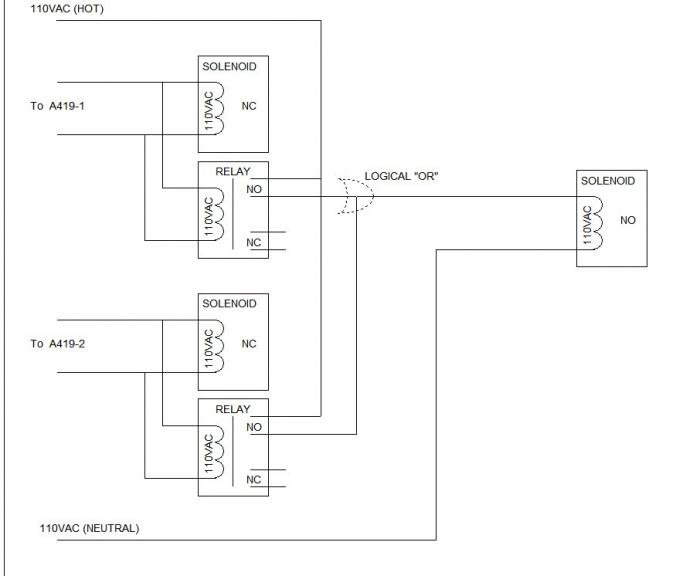

I have two normally closed 110v solenoids connected to basic 419 temperature controllers. When the temp falls out of range the 419 opens the solenoids. Chilled liquid will flow through these solenoids when open, and past when closed. Past both solenoids I have another 110v solenoid that is normally open. So when both normally closed solenoids are closed, liquid flows past and through the open solenoid.

But when one of the two (or both) of the normally closed solenoids is open, I need the normally open solenoid to close so the max flow is available to the open solenoid(s). Making this work with just one closed solenoid would be a piece of cake. But with two I have no idea if it's possible and how.

Anyone who has expertise in this arena have any idea? Each solenoid has just two wires (no ground) and polarity doesn't matter.

Any help would be appreciated!

I have two normally closed 110v solenoids connected to basic 419 temperature controllers. When the temp falls out of range the 419 opens the solenoids. Chilled liquid will flow through these solenoids when open, and past when closed. Past both solenoids I have another 110v solenoid that is normally open. So when both normally closed solenoids are closed, liquid flows past and through the open solenoid.

But when one of the two (or both) of the normally closed solenoids is open, I need the normally open solenoid to close so the max flow is available to the open solenoid(s). Making this work with just one closed solenoid would be a piece of cake. But with two I have no idea if it's possible and how.

Anyone who has expertise in this arena have any idea? Each solenoid has just two wires (no ground) and polarity doesn't matter.

Any help would be appreciated!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)