So here's what I'm looking at:

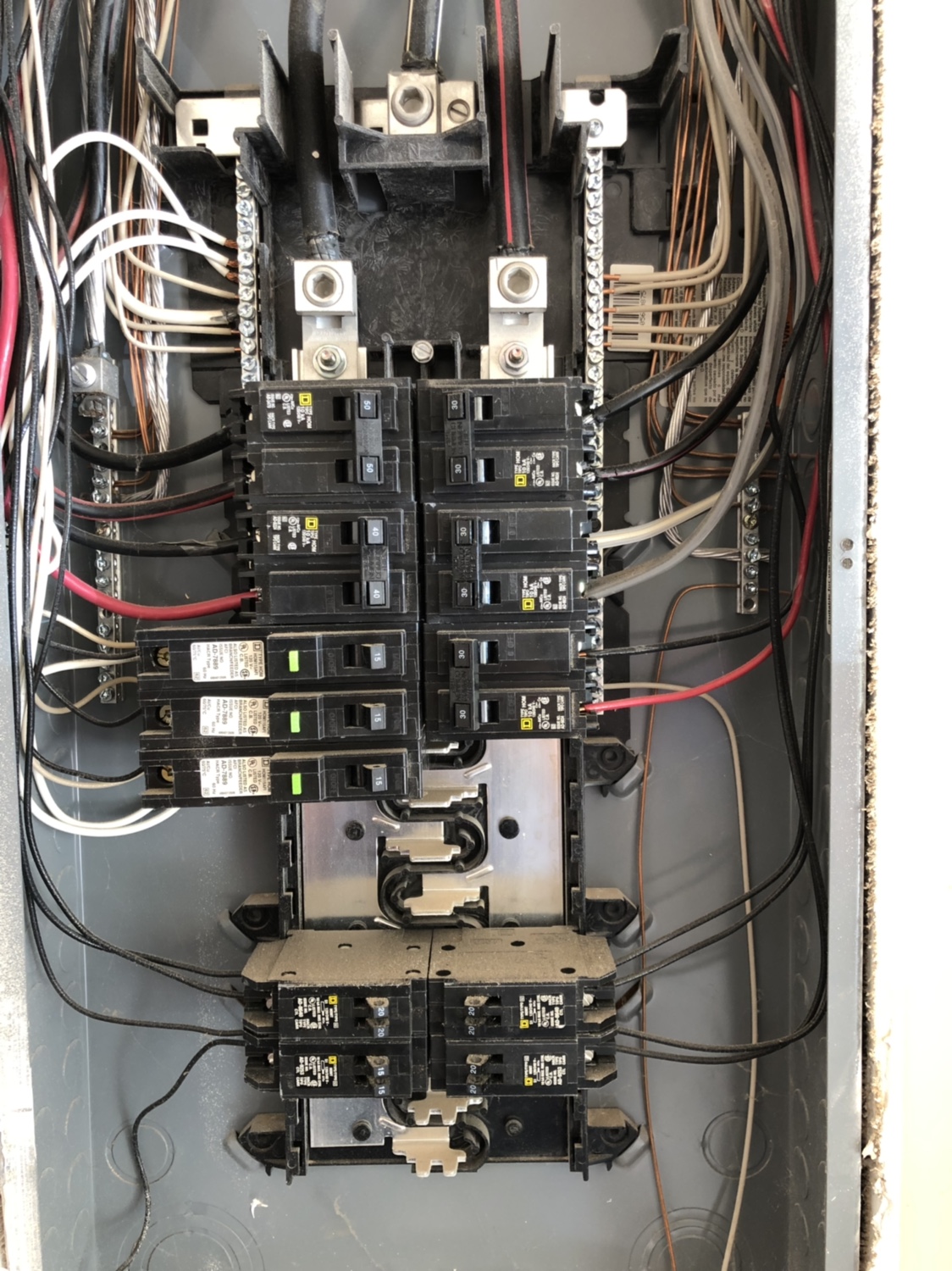

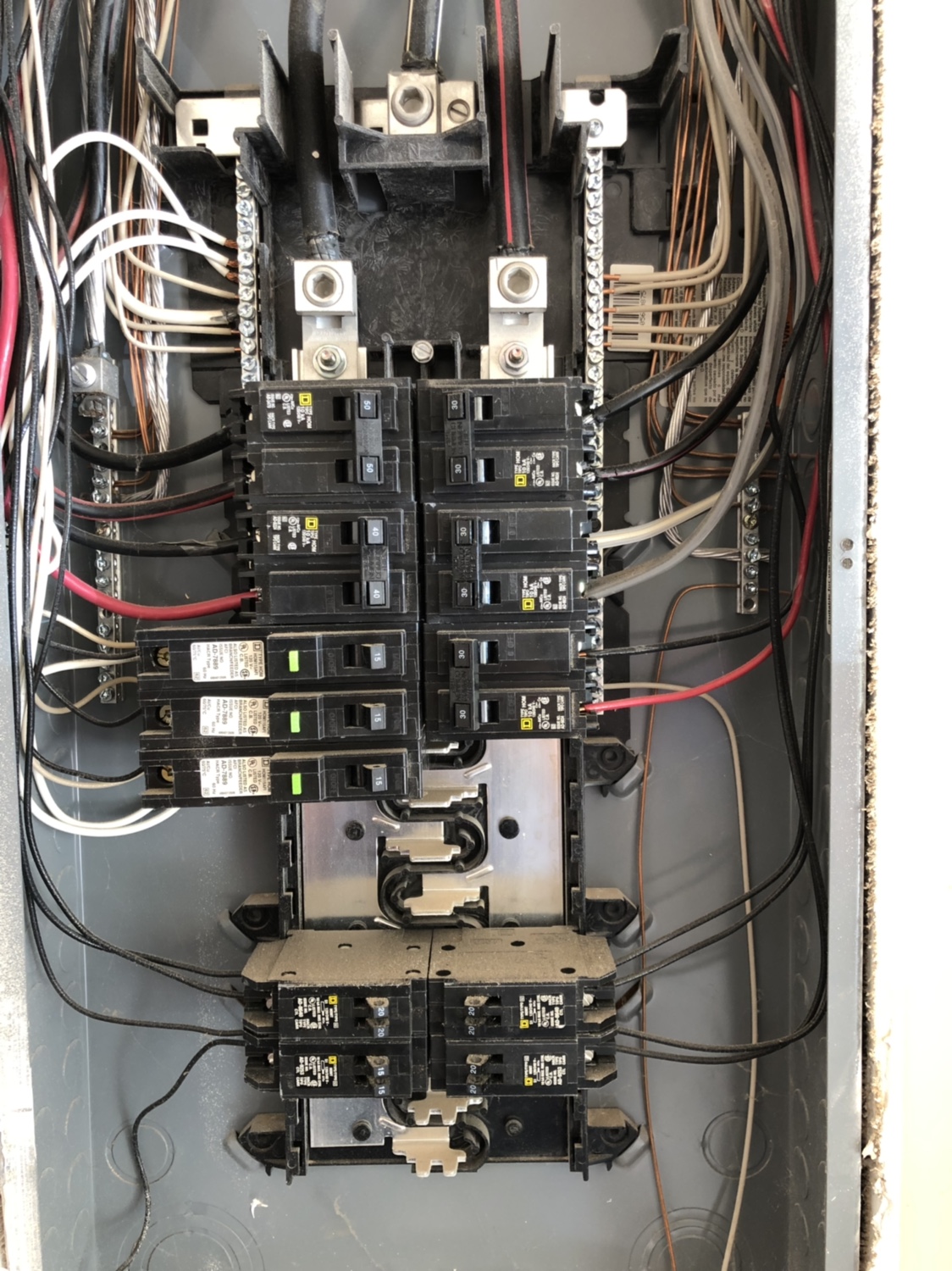

I have 200 Amp service to my house as shown below, and my main breaker panel is in my garage where I intend to brew. I have an Auber Brew Buddy 30amp brewery controller.

My service panel is in the photo below.

I intend to do the following:

1. Turn off the mains

2. Install a 30A GFCI breaker into my panel

3. Run a 1' ponytail of 10/3 from that breaker behind the drywall to a surface mount 14-30 receptical just below the panel

4. Run a 10 foot 14-30p to 14-30r extension cord to my panel

I have 200 Amp service to my house as shown below, and my main breaker panel is in my garage where I intend to brew. I have an Auber Brew Buddy 30amp brewery controller.

My service panel is in the photo below.

I intend to do the following:

1. Turn off the mains

2. Install a 30A GFCI breaker into my panel

3. Run a 1' ponytail of 10/3 from that breaker behind the drywall to a surface mount 14-30 receptical just below the panel

4. Run a 10 foot 14-30p to 14-30r extension cord to my panel

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)