Adrian Gresores

Well-Known Member

- Joined

- Nov 16, 2019

- Messages

- 49

- Reaction score

- 9

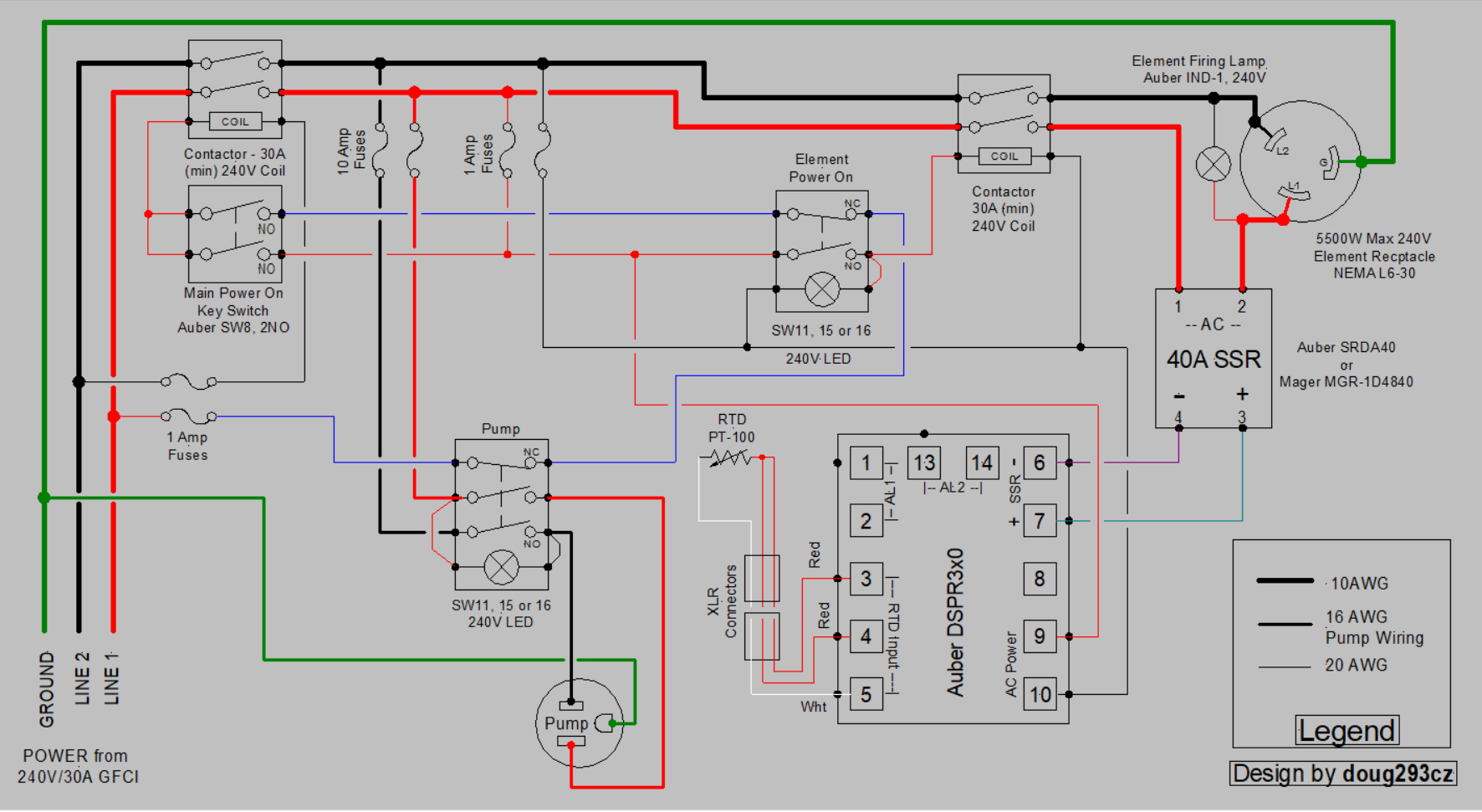

I am building a simple eBIAB system. Does anybody have a wiring diagram for a 240V control panel that includes a PID, 40A SSR, 5500W element, 240V pump, and receptacles for the element and pump? I would also like to have a switch and LED for both the element and pump. This will all be plugged into a dedicated 30 amp L6-30R wall receptacle, connected to a 240V 30A GFCI breaker. I would greatly appreciate any advice.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)