awoitte

Well-Known Member

- Joined

- May 9, 2017

- Messages

- 184

- Reaction score

- 21

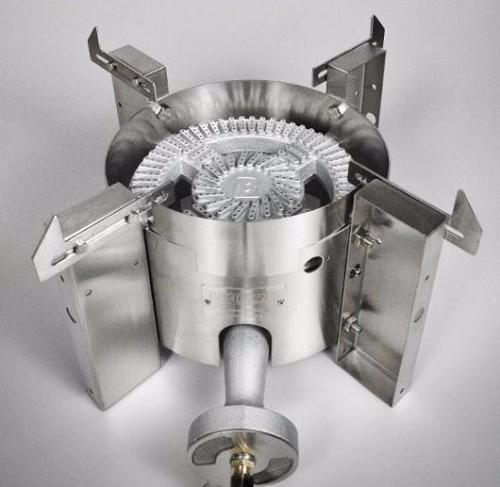

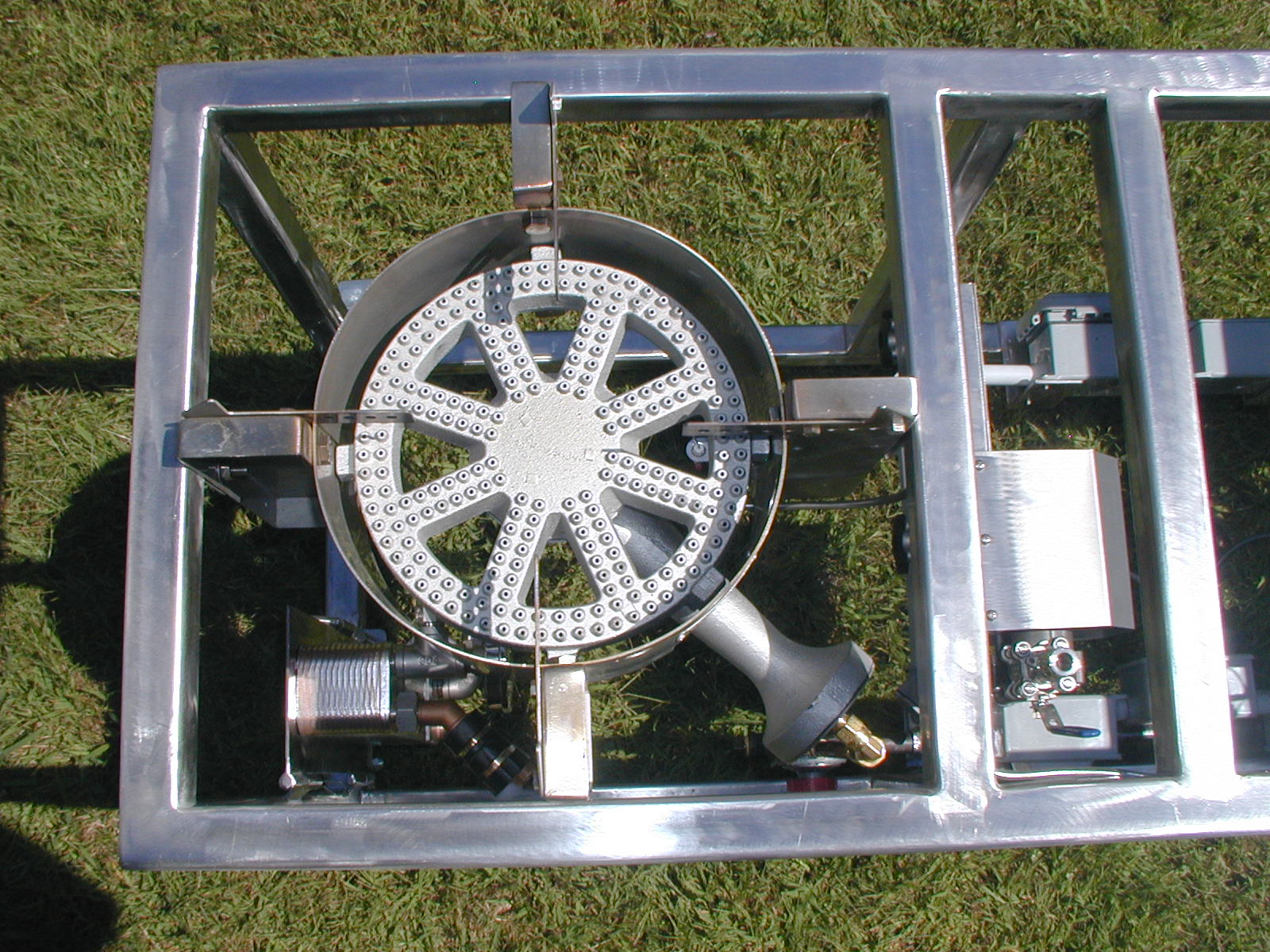

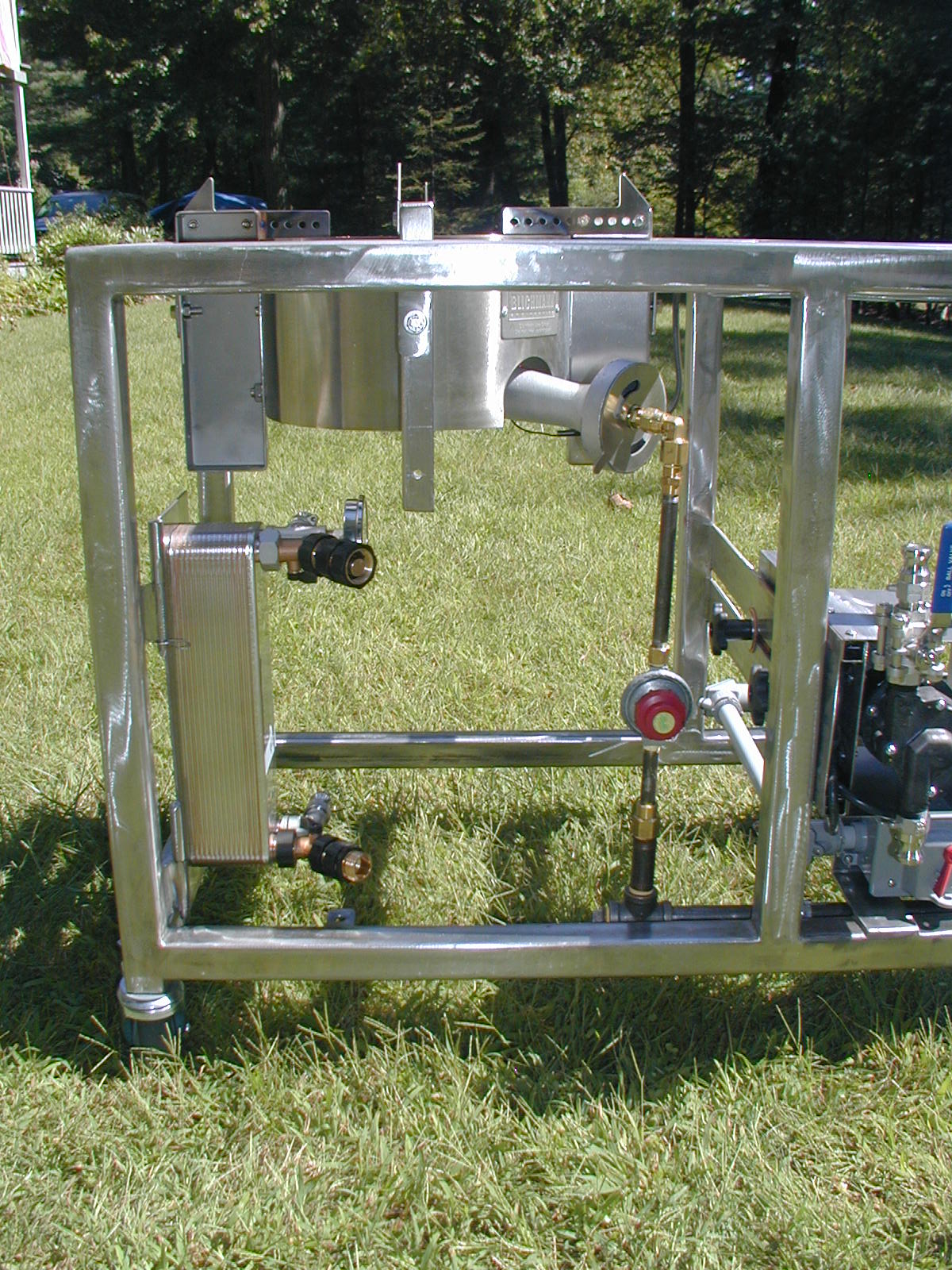

Here are some pics from the opening brew night on the rig. Real happy with the direct fired mash. With these burners I was worried they would create too much heat even on the lowest setting. Not so. When the temp hit 150 I would kick on the burners as low as I could keep it, and with a good recirc flow, it would take about 5 mins for it to get up to 154. Nice even temp rise. Otherwise, pretty uneventful. Next up is the Honeywell 8200 gas valve with standing pilot so I can actually use the output from my Auber controller.

View attachment 81389

View attachment 81390

View attachment 81391

Sorry for the thread revival, but what kind of tubing is that? Silicon, PVC, etc? Always curious about the tubing with the liner marks on it and what the difference is. If I recall its harder, I'm looking for something to put at the end of my counter-flow chiller as currently I have nothing but a male threading right off the the chiller. I think adding tubing will help with flow and increase cooling impact.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)