In 2013, we started the build of our forever home. We moved in during the summer of 2014 and I was itching to get to work on my own permanent brew space. Imagine my surprise when I discovered that there were a tonne of other 'more important' jobs to be done first.....

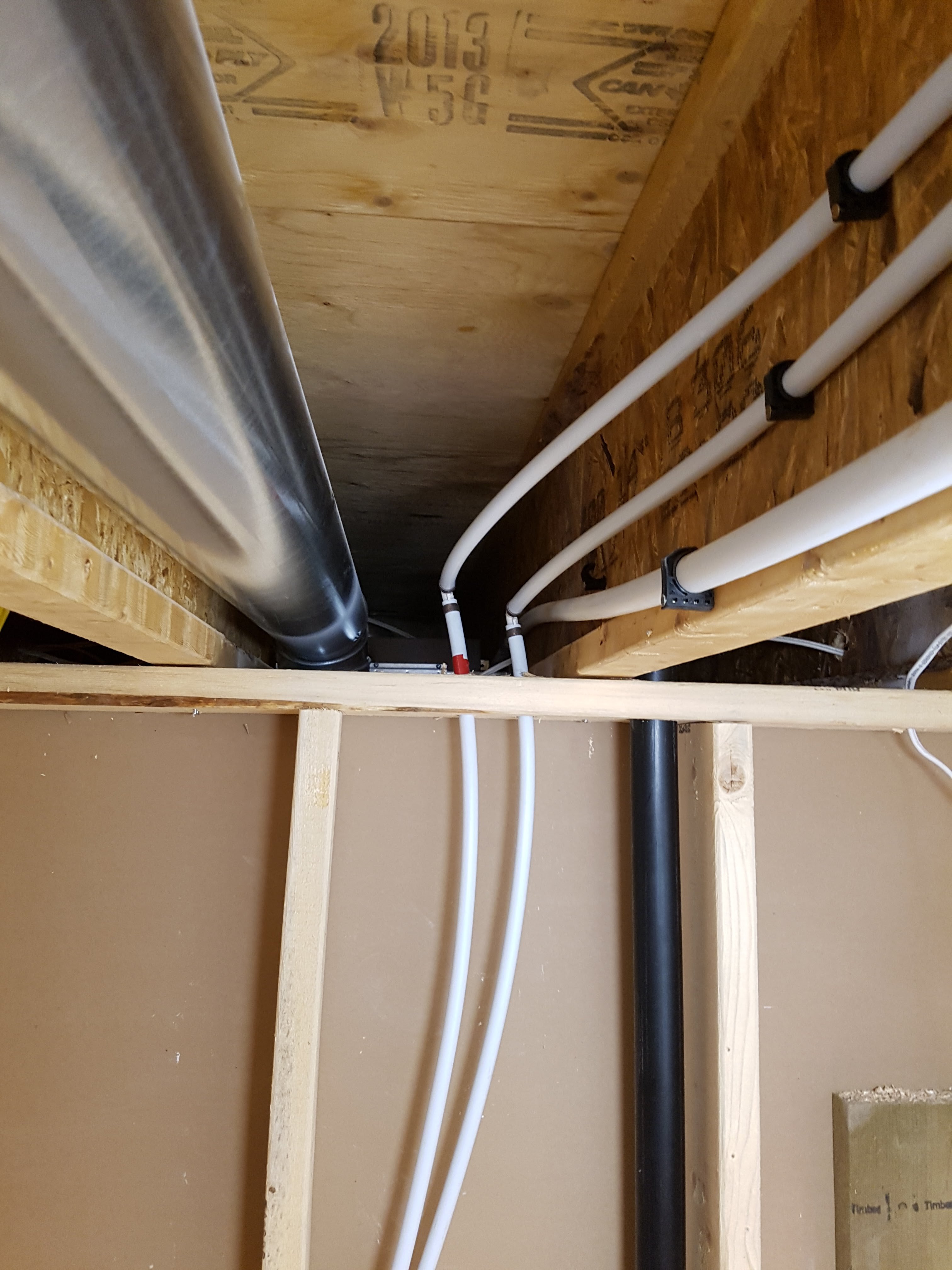

Fast forward to the spring of 2017 and I have finally started on my brew room. The space is unfinished 6'10" x 8'7" stud to stud and the ceiling is 9'6" to the bottom of the main floor joists. Sooo, lots of room I think. There is a straight run between the joists to an exterior wall for ventilation. Hot and cold water lines are also present and easy to access.

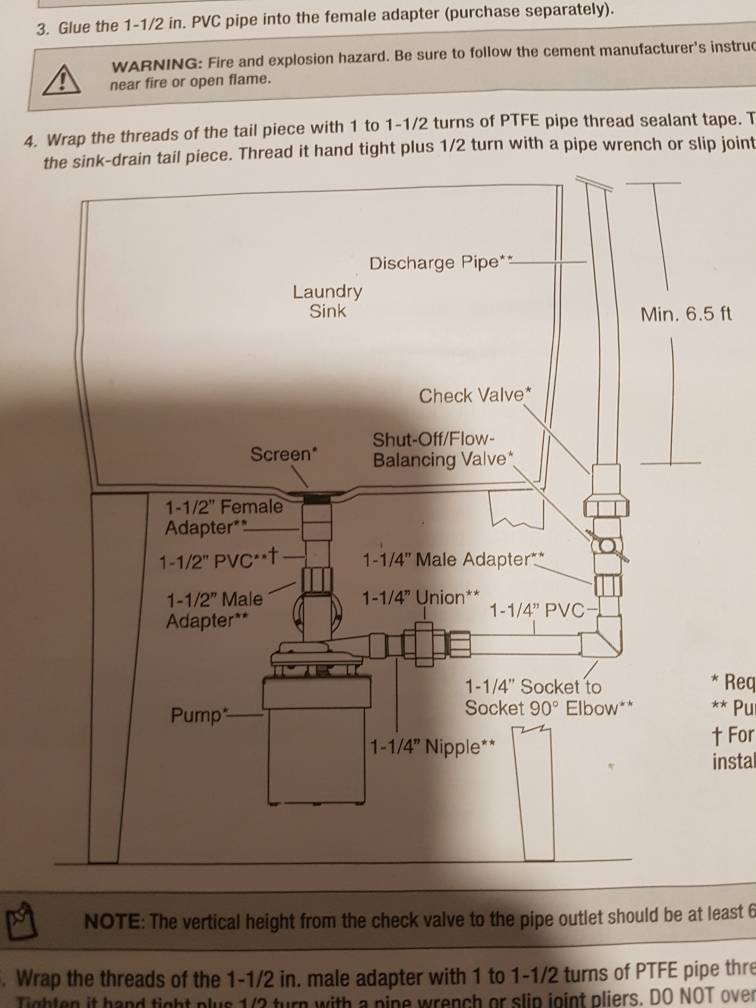

Drain for the sink is a minor issue as it is in the ceiling.... but there are pumps for that.

This will be an electric brewery using 2 of the Avantco 3500 Induction plates. I do 5 gallon batches and in my testing of these plates, I can get the required water to boil fairly easily. I have the two 240v 20a circuits in the room now.

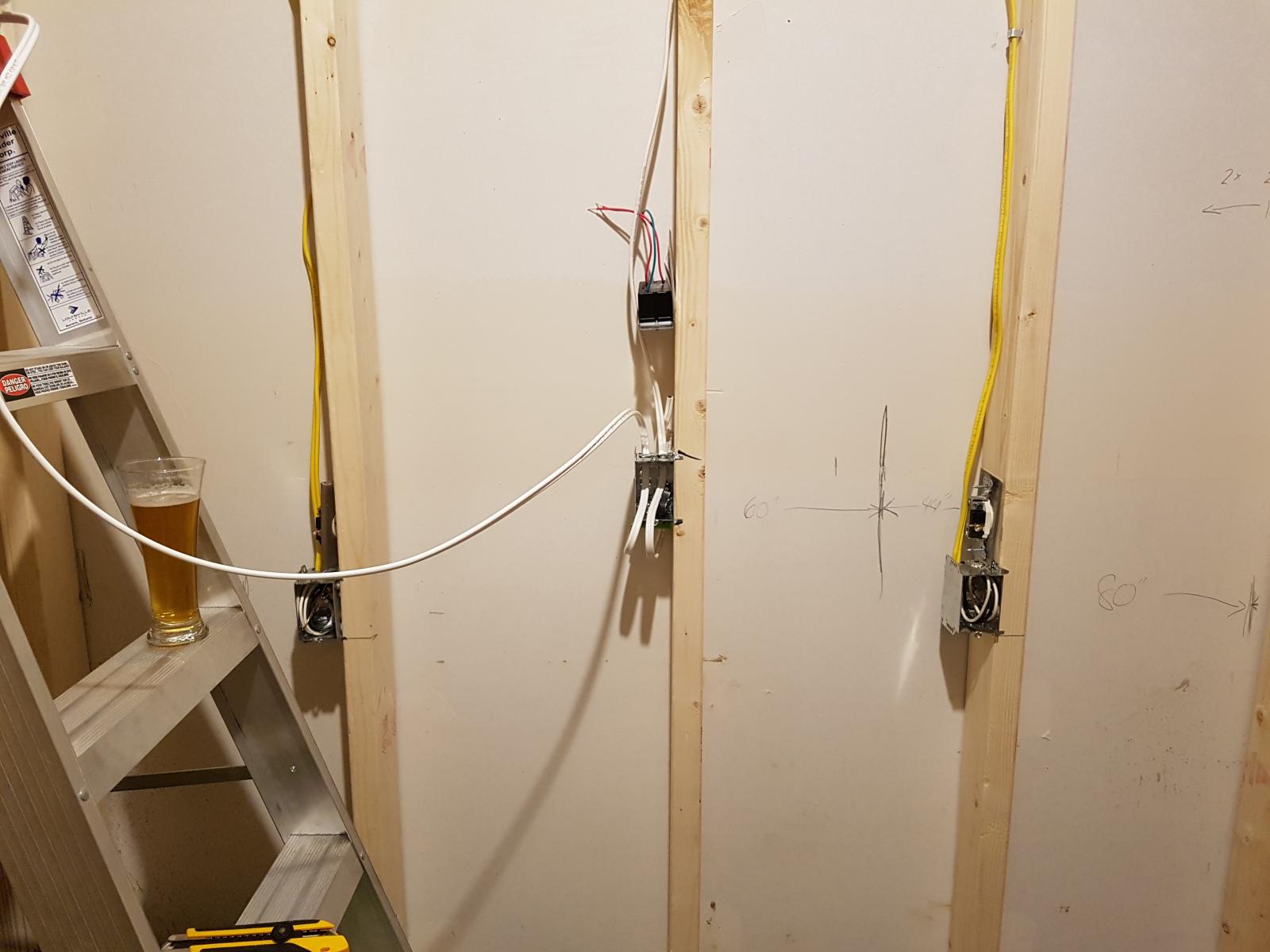

I believe that you can see the RDWAHAHB on the ladder. Also have the wire for the speed control switch for the Vortex in and am starting to run back to the panel….. Speaking of which...

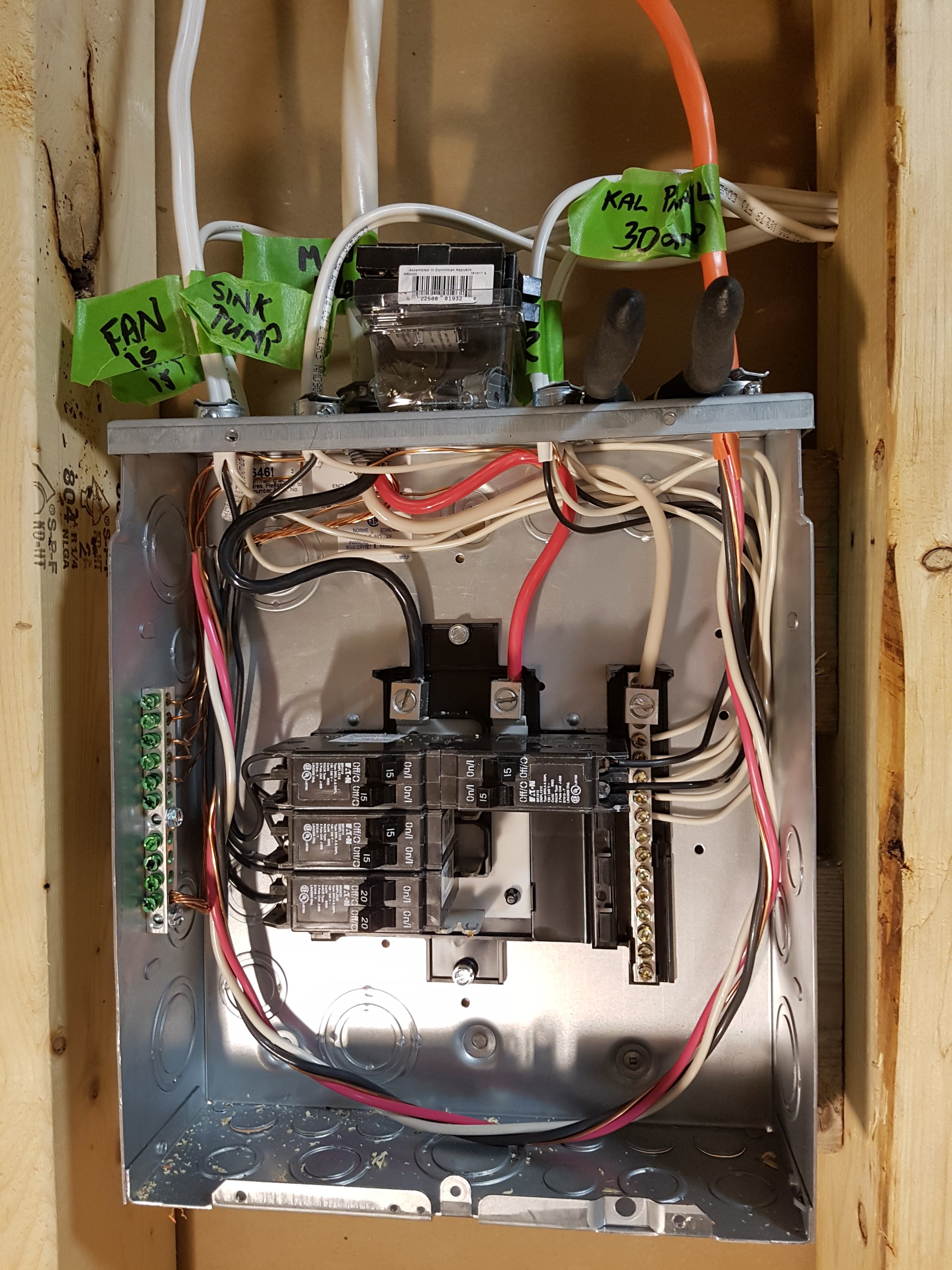

I have a sub-panel with 50a available for 120v circuits. So, I think I'm ok for electricity.

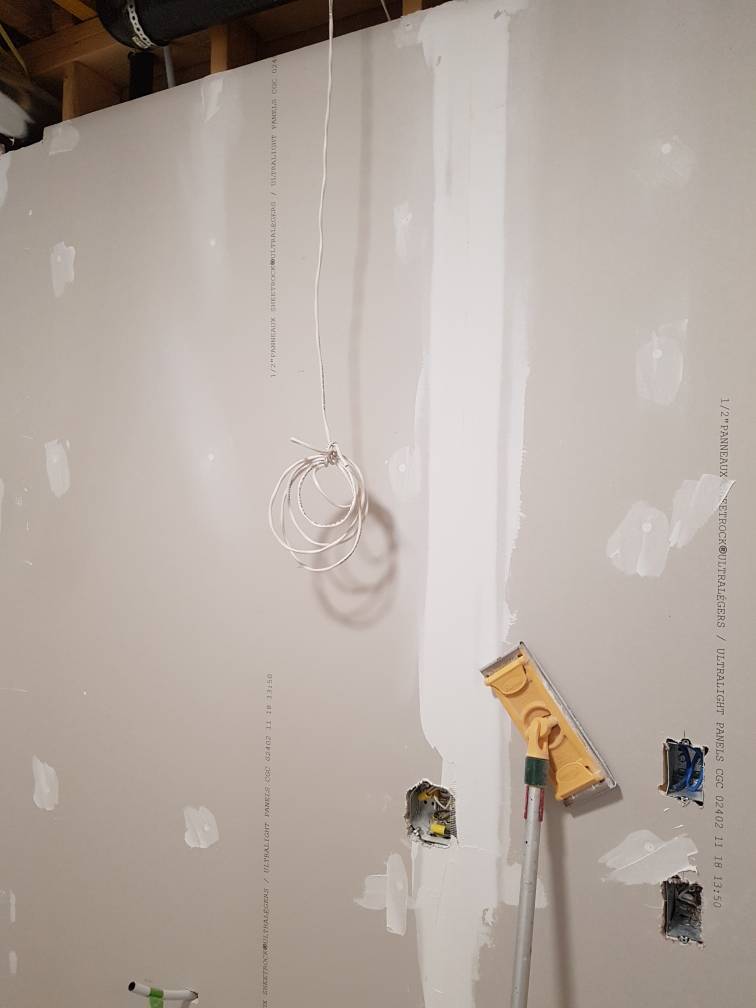

As can be seen, I have started pulling wire. The sub is live but just for the temporary circuit with a light on it. I have an electrician friend who will be connecting these circuits up to the panel when I’m done. The wall you can see to the left of the panel happens to be where my bar is so that’s where the kegerator (for now… keezer eventually) will sit with taps going through the wall to the bar.

I have the exhaust fan mounted and ready for ducting. Not sure what I’m gonna do for a vent hood yet. Depends on funds, I guess. I have a friend who bangs tin so may get her to fab me a hood out of galvanized.

I know that the keen-sighted are asking, why did he stud over the drywall there? And why is the framing for that wall a foot shorter than the adjoining walls? The house has ICF foundation and that drywall is covering the ICF. Rather than cut the drywall and ICF to run wiring and plumbing (cause the sink is going to be on that wall), I decided that this was easier. It’s a foot shorter cause my plan is to suspend a ceiling and it’ll be below that low top plate.

I will plan to keep this updated as the build progresses. Still a bunch of work to do but… it’s started…

Cheers!

Chris

Fast forward to the spring of 2017 and I have finally started on my brew room. The space is unfinished 6'10" x 8'7" stud to stud and the ceiling is 9'6" to the bottom of the main floor joists. Sooo, lots of room I think. There is a straight run between the joists to an exterior wall for ventilation. Hot and cold water lines are also present and easy to access.

Drain for the sink is a minor issue as it is in the ceiling.... but there are pumps for that.

This will be an electric brewery using 2 of the Avantco 3500 Induction plates. I do 5 gallon batches and in my testing of these plates, I can get the required water to boil fairly easily. I have the two 240v 20a circuits in the room now.

I believe that you can see the RDWAHAHB on the ladder. Also have the wire for the speed control switch for the Vortex in and am starting to run back to the panel….. Speaking of which...

I have a sub-panel with 50a available for 120v circuits. So, I think I'm ok for electricity.

As can be seen, I have started pulling wire. The sub is live but just for the temporary circuit with a light on it. I have an electrician friend who will be connecting these circuits up to the panel when I’m done. The wall you can see to the left of the panel happens to be where my bar is so that’s where the kegerator (for now… keezer eventually) will sit with taps going through the wall to the bar.

I have the exhaust fan mounted and ready for ducting. Not sure what I’m gonna do for a vent hood yet. Depends on funds, I guess. I have a friend who bangs tin so may get her to fab me a hood out of galvanized.

I know that the keen-sighted are asking, why did he stud over the drywall there? And why is the framing for that wall a foot shorter than the adjoining walls? The house has ICF foundation and that drywall is covering the ICF. Rather than cut the drywall and ICF to run wiring and plumbing (cause the sink is going to be on that wall), I decided that this was easier. It’s a foot shorter cause my plan is to suspend a ceiling and it’ll be below that low top plate.

I will plan to keep this updated as the build progresses. Still a bunch of work to do but… it’s started…

Cheers!

Chris

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)