tre9er

Well-Known Member

I've found that more magnets is always better -- you want a strong connection. But my 2" stir bar in a 2L starter is too hard for the fan to turn. A 1" stir bar in the same starter works fine.

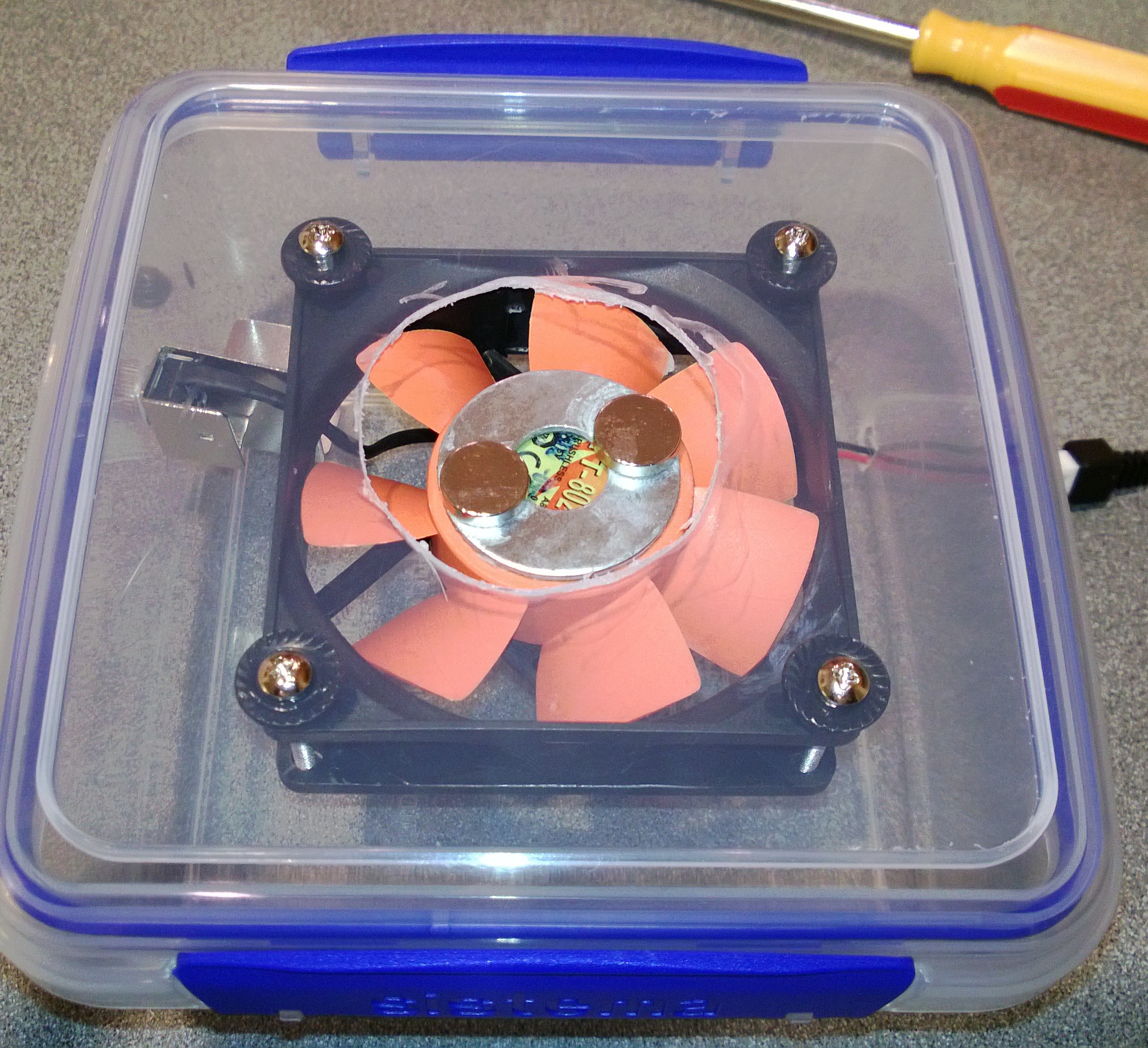

Well that stands to reason to a point, though. Stacking magnets brings them closer to the flask, too. Mine are darn-near flush with the bottom. These are strong-ass magnets, too. Hard to even separate by hand. I think being THAT close makes it difficult for a fan motor, used to spinning just a plastic blade, to spin the weight of the washer, magnets, and now the increased resistance from the magnetic force.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)