Hello everyone,

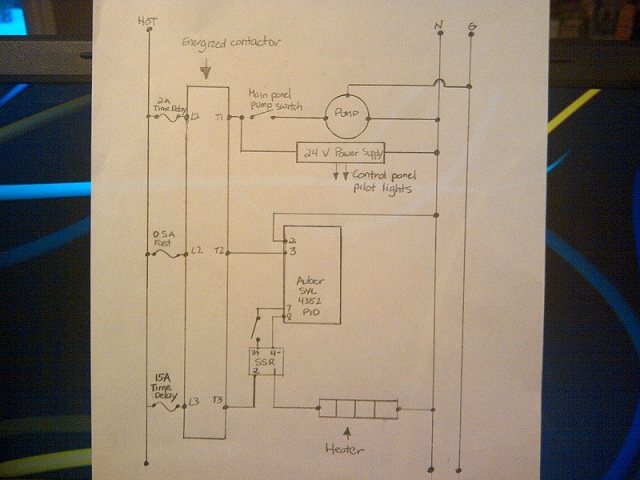

I have been brewing for about 1 1/2 years now and decided to up the ante and build a RIMS system. I started about a month ago and welded together the frame (which looks like a Brewmagic). I bought my kettles from Sabco and have been collecting the rest of the components.

Now that I have pretty much everything I need the work has been progressing nicely.

Here are a few pics

I have been brewing for about 1 1/2 years now and decided to up the ante and build a RIMS system. I started about a month ago and welded together the frame (which looks like a Brewmagic). I bought my kettles from Sabco and have been collecting the rest of the components.

Now that I have pretty much everything I need the work has been progressing nicely.

Here are a few pics

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)