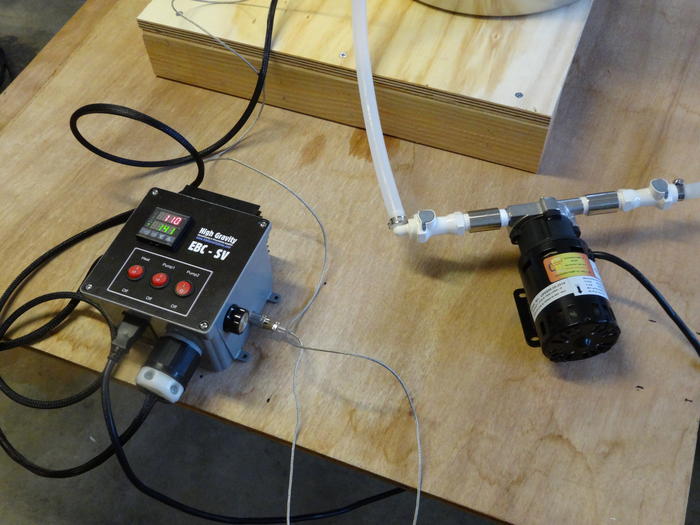

I just received my new High Gravity BIAB electric system. Works great!!

Observations

1. Take apart EVERY connection regardless if its pre-assembled and re-seal it with Teflon.

2. Run a test with water only with heat to ensure everything is sealed.

3. VERY quiet operation in fact it almost feels like I am cheating when using

4. Pick location for a pulley for grain basket

5. Elevate the pot at least 4 inches. It makes using a plate chiller very efficient with no pump needed.

6. Very easy to clean as I ran it at 140 for its first cleaning for an hour while recirculating.

7. Heating element is a pain in the ass to get sealed...Sometimes water leaks through the threads so Teflon the hell out of it and it will be fine.

8. Shipping is VERY fast and the overall quality is great

9. Not sure on efficiency yet however, I will brew a big Belgian using a recipe I have and double crush and add 2lbs additional base malt and see what happens.

Observations

1. Take apart EVERY connection regardless if its pre-assembled and re-seal it with Teflon.

2. Run a test with water only with heat to ensure everything is sealed.

3. VERY quiet operation in fact it almost feels like I am cheating when using

4. Pick location for a pulley for grain basket

5. Elevate the pot at least 4 inches. It makes using a plate chiller very efficient with no pump needed.

6. Very easy to clean as I ran it at 140 for its first cleaning for an hour while recirculating.

7. Heating element is a pain in the ass to get sealed...Sometimes water leaks through the threads so Teflon the hell out of it and it will be fine.

8. Shipping is VERY fast and the overall quality is great

9. Not sure on efficiency yet however, I will brew a big Belgian using a recipe I have and double crush and add 2lbs additional base malt and see what happens.