That is quite an impressive job you did! I think that is about the best one that I have ever seen. Love your work space and there is a ghost in the photo in thread # 10 LOL. Again great job! Cheers

No check valve, but yes, you'll note the regulator hanging off the supply tank (a couple pages back). I set it for 15 psi which surprisingly is plenty.

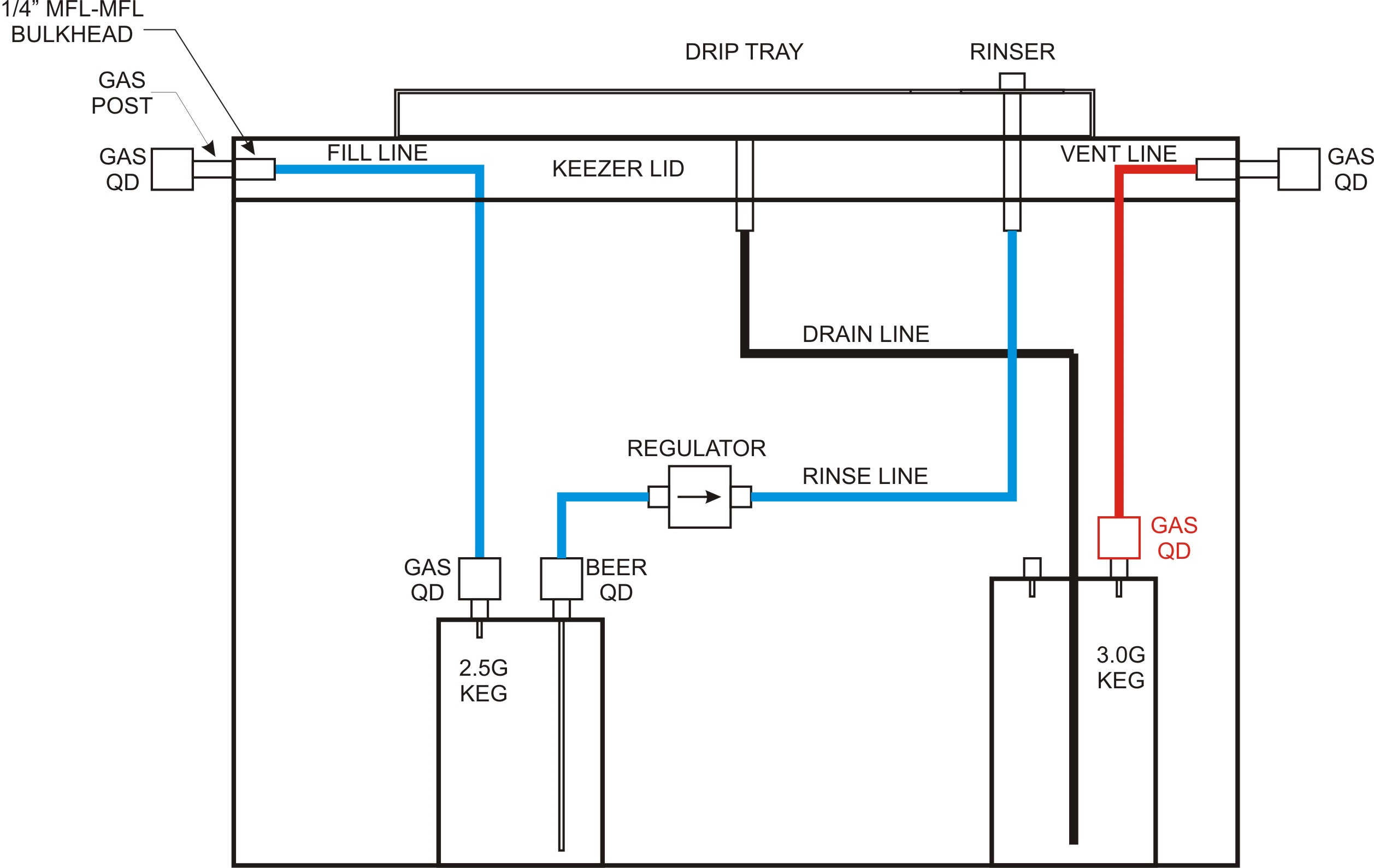

As this is a closed system (I fill the tank via a dedicated bulkhead port) I don't think there is need for a check valve anywhere as there's nowhere for the tank water to go but the rinser

btw, I have a Krome Dispense SS surface mount rinser from my old "K2" build. If you're going to build up your bar surface from a supporting substrate (like using tile over plywood) you could set it down and tile around it and it'd stand proud by ~1/4"...

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Very nice. Detailed and thorough. OK, when are we all coming over for homebrew?

So, I may have missed this because I’m not on the board very long - but what do you do or did you do for a living? This is just, I have no words besides beautiful.

It takes a lot to impress me, but here I am!

Amazing job!

Wow. Just wow. I'm a newbie to brewing and wine making, and even I can tell this is incredible. All your friends are going to want to party at your house now lol. Cool handle BTW.

OK - you are making me jealous on so many levels!

Beautiful build!

That is quite an impressive job you did! I think that is about the best one that I have ever seen. Love your work space and there is a ghost in the photo in thread # 10 LOL. Again great job! Cheers

As a computer engineer who works in military vehicle cable harness design and electronics integration, I'm fascinated by your controller and electronics setup. Are you able to provide details on your brewery controller?

I gathered you're running Raspberry Pints and BrewPi. Is it a custom Raspberry Pi enclosure?

Also, do you have more details about the various in-out connections on the rear of the lid? LP CO2, HP, CO2, etc.

All I can say is WOW!

Also curious about the different gas inputs and outputs on the lid and more detail on the rinser and drain set up please.

How hard is it to get the kegs in and out of there?

Wow, what an amazing job!

Thank you

So...in the "Before Times"...between sons, friends and neighbors I could count on a keg kicking every week to week-and-a-half through most of the year, and for a number of years I was hitting the Federal limit for two to keep up. But everything slowed waaay down with the pandemic - we literally have not had a single soul outside of my kids/DILs/grands over the house since March 6, 2020, and even those visits were cut maybe in half due to freak-outs and the like (fwiw, across the entire extended family, so far only my youngest grandson - the one in day care - ever tested positive, and he flew right through it like it was barely even a cold).

That said, I took it upon myself to make up for the slow down as much as possible and still managed to knock out 140 gallons in 2020

Cheers! (It's a tough job but someone had to do it)

Digital Equipment Corp and did memory system designs and processor architecture stuff during the Alpha chip era in the 80s,