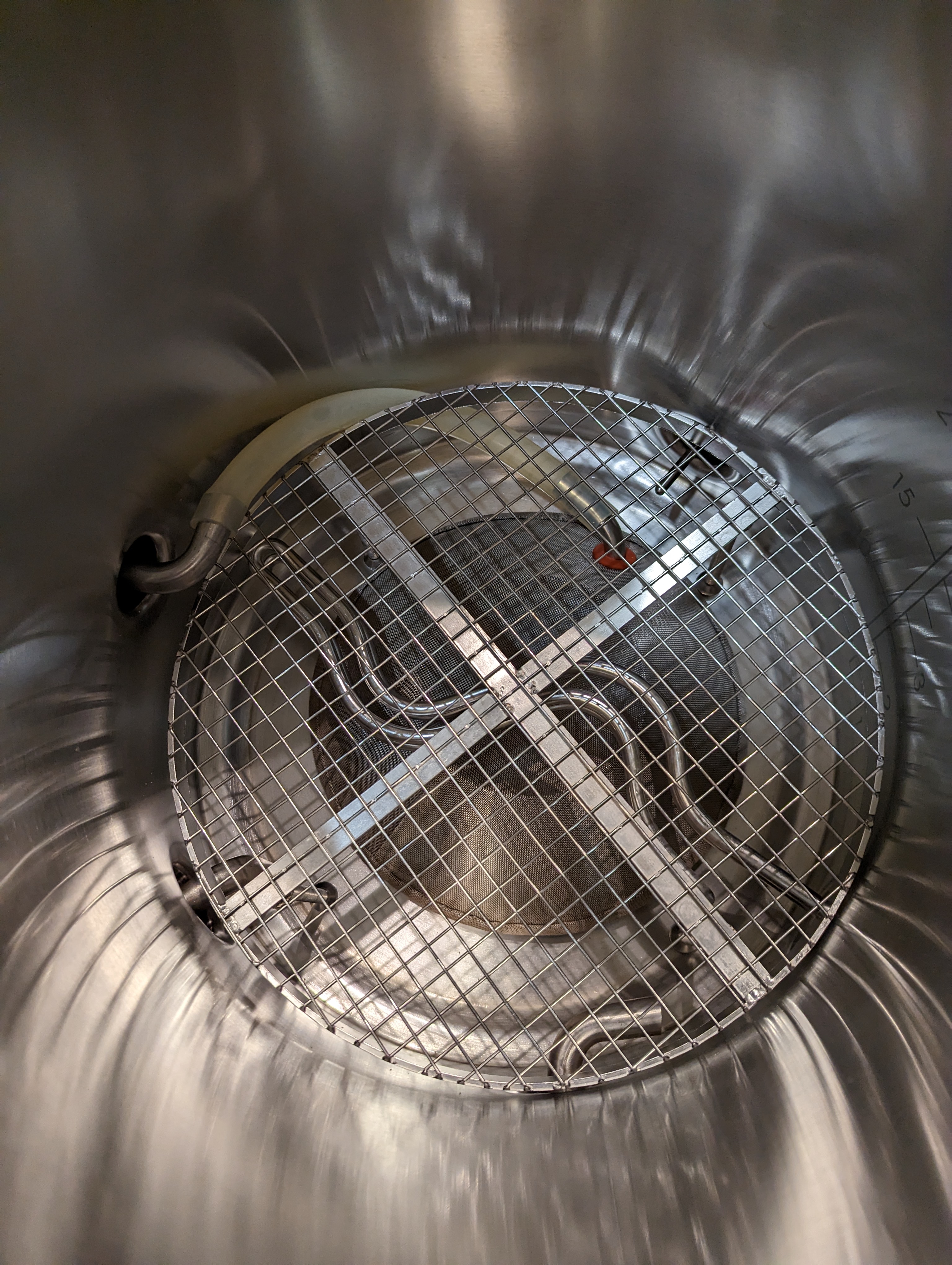

Well, I finally brewed for the 1st time since I bought the Hopstopper ~2 months ago. Unfortunately, I had 2 significant failures. I stated earlier that I electric brew with induction, but didn't mention that it is BIAB also. I should have been clued in when I heard boiling action when beginning to heat the wort after mashing when the mash temp was barely elevated. I figured there was some localize heating, but didn't think about scorching, having never experienced it. Needless to say, the Hopstopper on the bottom of the kettle results in significant scorching with induction, which is pretty obvious in retrospect. Therefore, it looks like I'll have to be installing the modifications you guys have made for gas brewing. The space on the sidewall of the kettle during mash will restrict the area for the bag, but probably no more than the "false bottom" needed to keep the mash weight in the bag from crushing the Hopstopper.

The beer was a WC IPA with 12oz of late addition loose hops for the HS to filter. I've decided to go forward with the beer in spite of the scorching. I couldn't detect anything in tasting the wort, but I'll taste again before dry hopping. So, the large amount of hops led to the 2nd failure. I had "calibrated" and marked the position of the ball valve for 1 GPM flow ~6 weeks ago, but was slightly confused about how to interpret my mark since it had been awhile. When I started the pump, the flow definitely seemed too high. Instead of just shutting the pump off and readjusting the valve, I adjusted it on the fly and very briefly increased instead of decreasing flow. I quickly adjusted, but the damage was done. It was pretty evident that I had pancaked the HS2. The flow eventually dropped to a trickle, at which time I decide to stop draining, insert a sanitized gloved hand into the wort and remove the HS2 and dip tube. I cleaned the HS2 and attempted to restore its shape before soaking the assembly in Starsan and reconnecting and resuming draining. 20 minutes later and the flow basically stopped again, with 5 of 10 gallons in the fermenter. I finally decide to bypass the HS2 for the remaining wort. Even with this, the amount of trub into the fermenter was maybe 1/2 or 1/3 what I previously have gotten. I'm looking forward to using it correctly in the future.

So this beer has scorching and a risk of infection. I hope that sharing my boneheaded brew day will help the rest of you avoid my mistakes. I will look into trying to add some short pieces of stainless tubing to act as "tent poles" inside the Hopstopper to prevent pancaking. This seems like something that could be added pretty easily to the design initially.

), then start the 1 gpm runoff to the carboys. So, not setting any real time aside for settling...

), then start the 1 gpm runoff to the carboys. So, not setting any real time aside for settling...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)