EvilTOJ

Well-Known Member

I've actually made concrete rollers as well, but it never worked because I could never center the axles exactly. I guess I feel better that it took you having a lathe (which I don't have) to get them exactly centered.

.... I could never center the axles exactly. exactly

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

i've been thinking of doing something with concrete rollers and i stumbled across this thread,just wondering,how is the surface of the rollers holding up?

I plan on doing something similar.

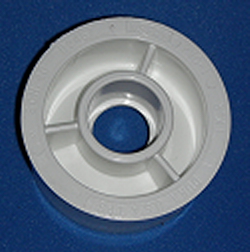

To form the rollers a 6 inch by 3 inch diameter pvc pipe will be fitted with a 3 inch to .5 inch reducer an each end (see pic below) and and have a .5 inch threaded rod centered in the two fittings. Once the form is assembled with the rod in place it will be filled with cement and left to cure. Once cured the pvc mold is cut away leaving a perfectly round roller with a perfectly centered shaft.

Since the PVC pipe is perfectly round and so are the fittings everything is centered.

What do you guys think???

Here is a pic of the reducer from flexpvc.com

Hhhhhhhuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuugggggggggggggggggggggggggeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeee

So impressed! I was going to use a different method, but this is THE BEST!

Am wondering, how did you get away from some diagonal lines carved into teh idler roller?

Slim49

TH,

from my research over years, I note that the "Stones" in any mill are scored or grooved.

I wonder if you were to take a 4.5" angle grinder & cut in diagonal grooves across teh face of your rollers. would it improve the crush & perhaps unload the motor as a happy extra?

Slim49