Thought I'd share after lifting several ideas I've found here and elsewhere on the interwebz:

A couple things of my own:

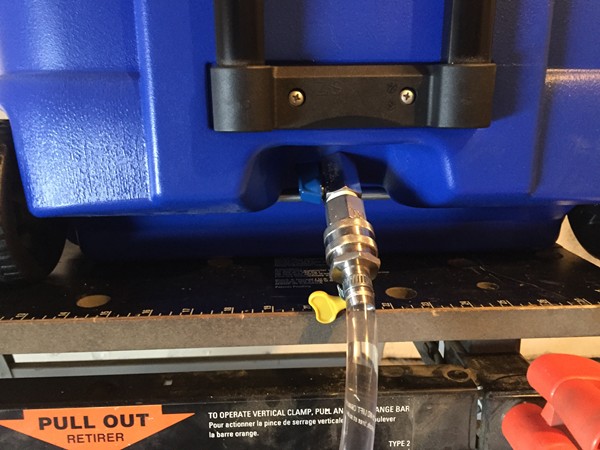

-Stainless QD's

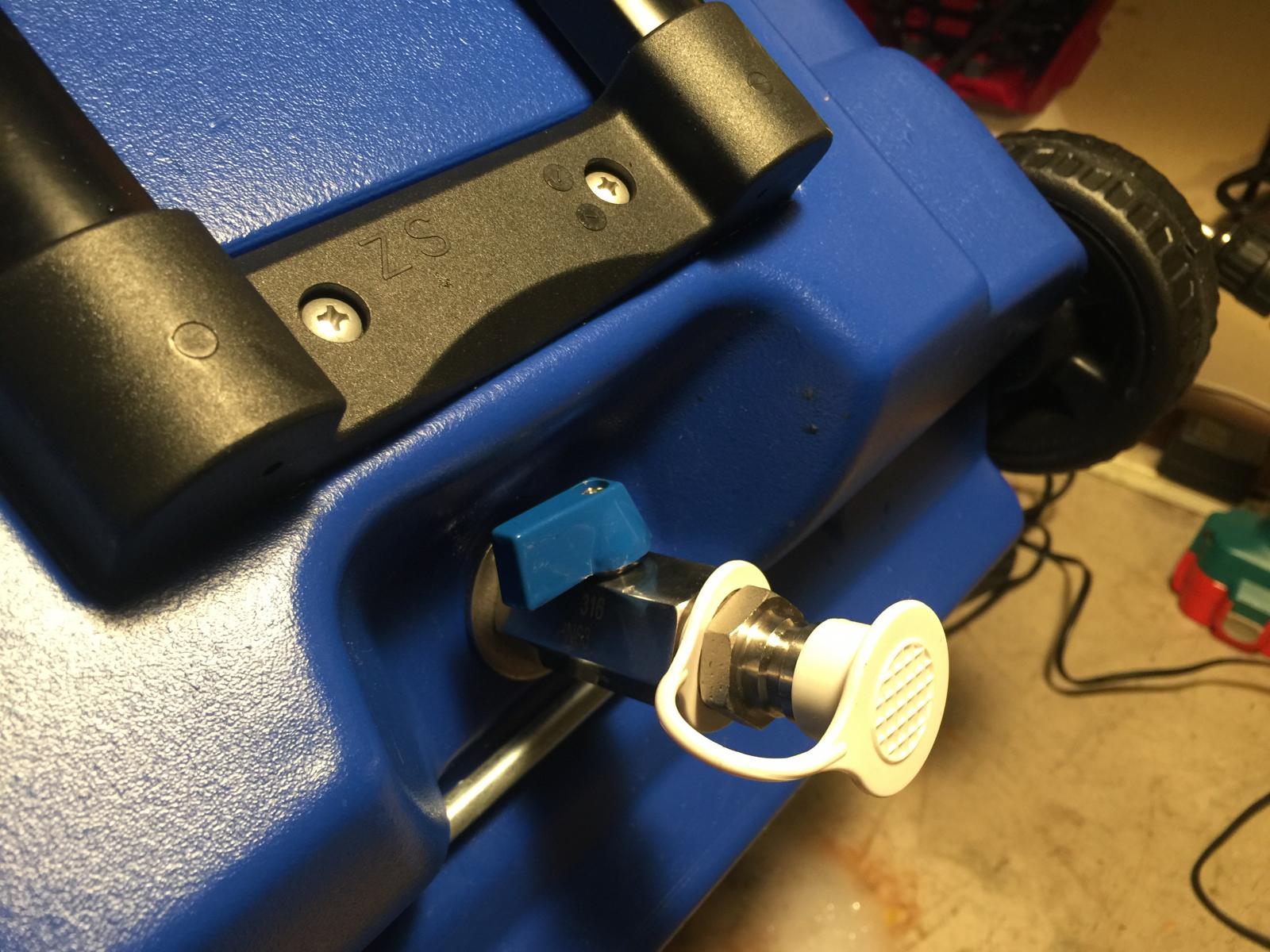

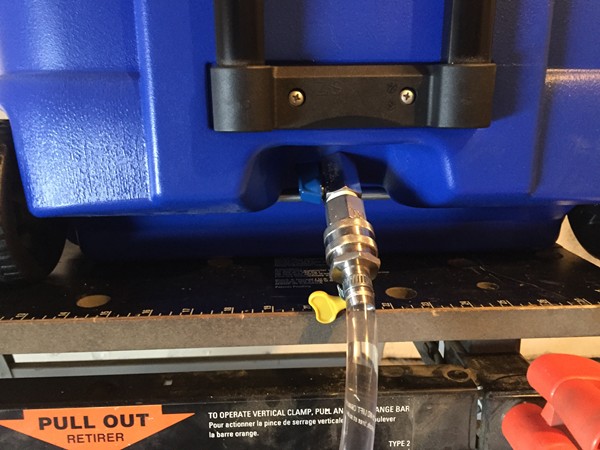

-Mini ball valve on mash tun

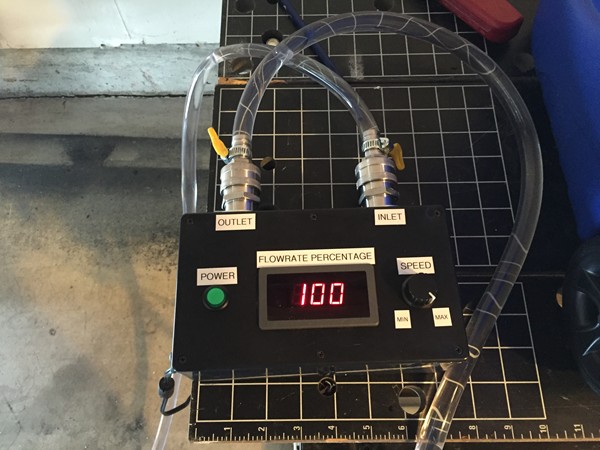

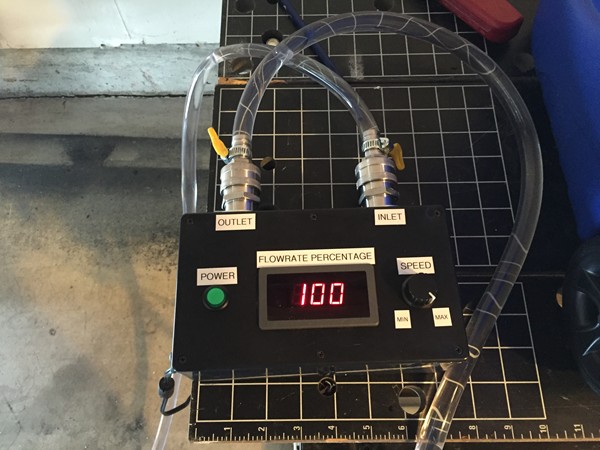

-Built the small xfer pump with a food grade hot water pump and added a variable speed control

Some good ideas found online I incorporated:

-Removable manifold

-Small slits on bottom of manifold

-Expanding-foam insulation inside lid

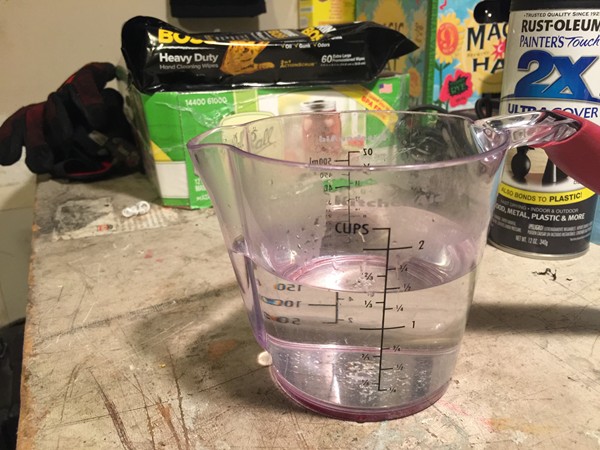

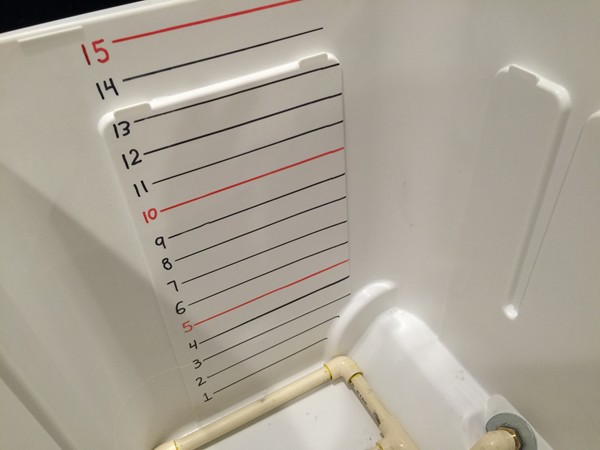

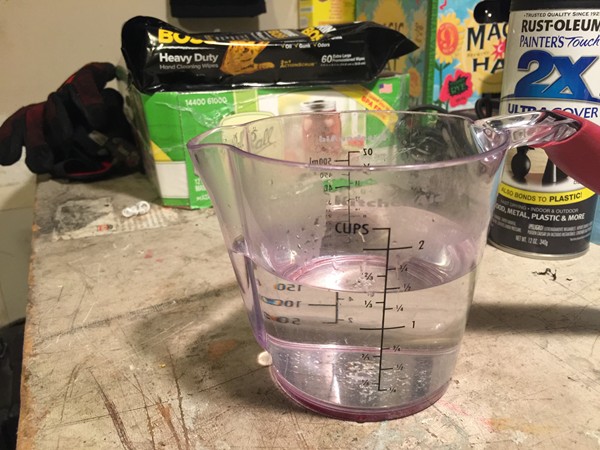

I tested today, and in my ~42 degree garage, I only lost about 3 degrees over the course of an hour, so it's insulated reasonably well. I also only lost about 350ml of liquid at the bottom of the tun.

Appreciate everyone who shared ideas...

-sc

A couple things of my own:

-Stainless QD's

-Mini ball valve on mash tun

-Built the small xfer pump with a food grade hot water pump and added a variable speed control

Some good ideas found online I incorporated:

-Removable manifold

-Small slits on bottom of manifold

-Expanding-foam insulation inside lid

I tested today, and in my ~42 degree garage, I only lost about 3 degrees over the course of an hour, so it's insulated reasonably well. I also only lost about 350ml of liquid at the bottom of the tun.

Appreciate everyone who shared ideas...

-sc

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)