thanks dude,

I have brewed in the shed a few times now and I love it!

BUT the last time I did (July 4th) it was over 90* here and inside the shed was even worse! Not sure I like that at all.

Had a big fan blowing heat out and that helped but still was so hot in shed..

My friend who was helping me brew that day is an electrician so we where talking all about wiring the shed.

He gave me some good pointers and offered to help in the future.

Since I am running power to the shed I am going to save and try to at least run 1 30amp plug for future electric brewing.

It would be so nice to work inside with the door closed and a AC running in the hot summer. LOL

And as you all said before, door closed in winter and free heat from kettles.

So that is all still in planning.

But here are a few pics from my last brew day.

lol this worked great!

pumped water through my 50' 1/2" immersion chiller then back into my rain barrel to be used to water garden later. I was surprized how much water was used in cooling process. it filled up tote to bottom steal bar.

In the future (next few weeks) this rain barrel will be all setup and working.

So in the summer at least I can use my solar / battery powered 12v 300gph pump to pump the rain barrel water to my chiller then back into bucket.

Just something fun I figured I could do with my rain watering setup in addition to watering garden.

We used my old wort chiller as a pre-chiller in the beer cooler we where using at the time.

cooled down on its own whirlpooling in 10 min or less.

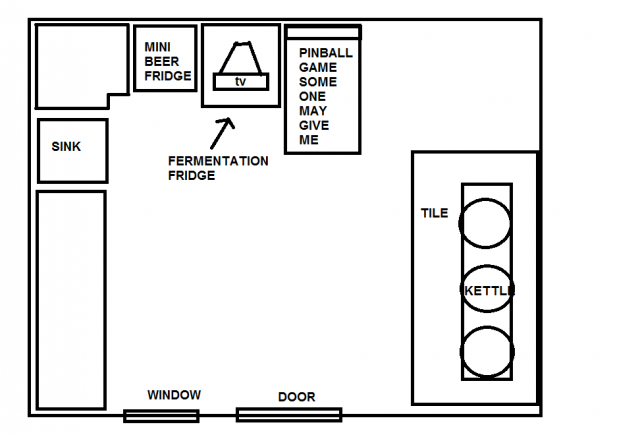

I have decided I want to get some tile and make a rectangle pad under the brew kettles. Kinda like a stove hearth.

That way for now I don't have to worry about the heat heating up floor.

Also if I spill on the laminate over time it will ruin it.

I would love to have the wall behind my kettles be that stainless steel mirror like restaurant stuff.

here is a pic of what it will look like when done..

a family member is pawning off a pinball machine on me I hear soon. I don't have room in my house so it may go in the brew shed.

Pic is not to scale just a quick MS paint drawing to show you my idea.

thanks all

post progress as I make it.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)