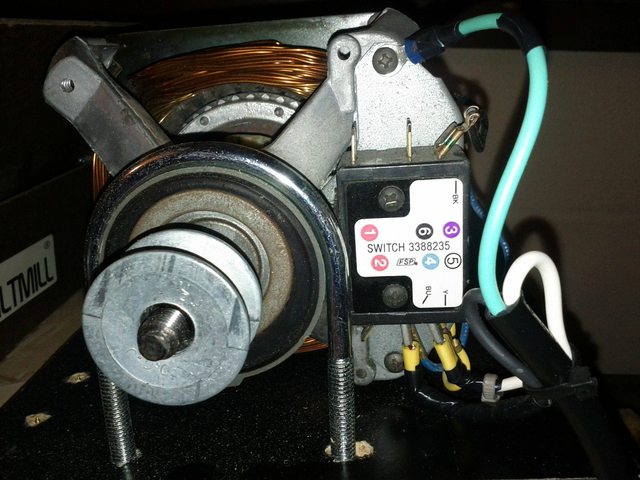

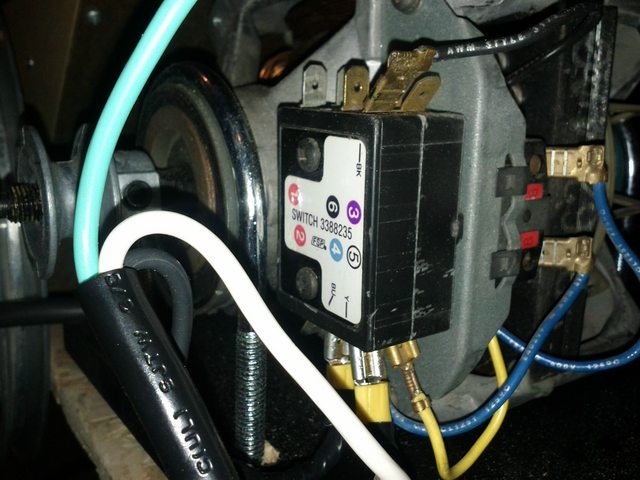

Used Dremel to create a flat on the motor's opposite driveshaft to correct rotation problem. Sheave was loose. Picked up 1/2" to 3/8" shim to correct diameter. Shim was too narrow to fit onto the shaft.

CW-rotation driveshaft turns out to be a different size than the CCW-rotation shaft was. Spent hours using Dremel to reduce driveshaft diameter by hand.

Got motor to successfully rotate mill. Then, put a stress crack into the 2'x2' plywood base due to a weak spot in the deck material, and engine torque. Also encountered belt slippage under load. Devised method to regulate engine belt tension. But, I put further cracks into the motor mount platform during experimentation/testing phase. ARGH.

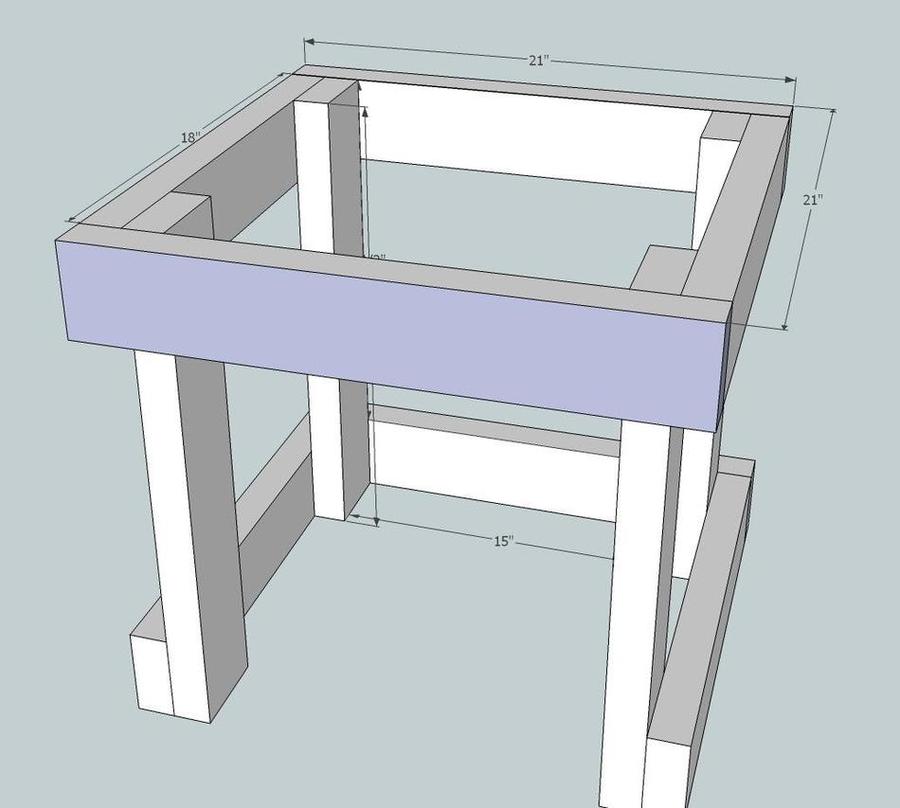

Went to Menards, picked up a 2'x4' of good, 3/4" thick hardboard. Then, I cut a new 2'x2' base, new 8.5"x10" motor mount, new 9"x12" hopper adapter mount. Planned to do the mount now, and the base later.

I traced and drilled the new motor mount. Remounted motor, troubleshot issues. Because I did all of the tracing freehand using the motor mount that had initially been designed for reversed orientation, I was off on a few measurements.

Got mill entirely reassembled and tested it with power again. The pulley alignment is worse than it was on the old mount.

And the weak spot in the 2'x2' is bad enough that the top deck is flexing up and down as the motor chugs along. It's too weak to put off fixing until later. So, the mill is stripped all the way back apart and has the top torn off of it. I'm re-tracing the new top deck and hope to have it finished tomorrow maybe. At least it'll look quite pretty once it's done.

But at this point, the motor/mount assembly, including tension regulation bolt, should all be 100% done-zo. And likewise, wiring is already solid. Just got to measure, cut, drill the top deck, Dremel out the barrel hinge grooves, sand down the grain chute opening, and then it should be operational!

After that, all that remains is double-checking my template on the hopper adapter, drilling cutting and sanding, followed by cutting the Large Hopper (plastic trash can), joining and sealing, and testing!

Once those are done, all that remains is putting together the pulley safety cover, both top-side and bottom-side.

And also cutting dust containment panels (1/4" hardboard) for the four sides, sanding down the front corner of the 2x4" to make easier bucket ingress and egress, and caulking all the seams.

YAY!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)