Huaco

Well-Known Member

Where did you get the motor and gear box? Looks GREAT!

Where did you get the motor and gear box? Looks GREAT!

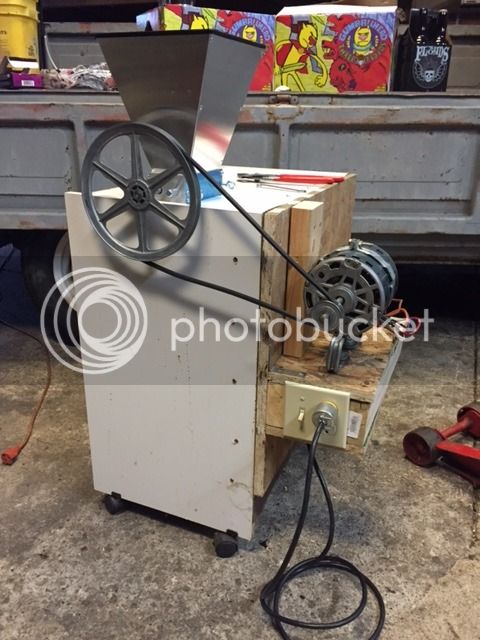

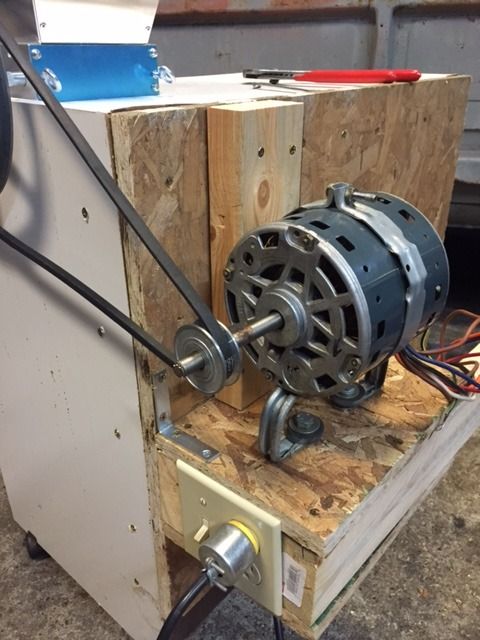

I have the monster mill MM2-2.0 and it needs more power and slower speed than most. With gear drive, the torque goes up when speed goes down. I'm sure that is obvious but it means I had to be selective with surplus motors. This mill needs 160-180 inch pounds if you want to crush anything at any gap. Since I only have a motor with 140inlb, it stalls with a lot rye or carapils if I try to crush very fine. I'm running 63 RPM but would go to about 100 or 120 if I could hand pick. Again, a 2" roller runs grain faster than the 1.25 or 1.5" rollers at the same rpm.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I've got a MM3-2.0 and I'm using a 1hp 1725rpm motor with an 10:1 reducer with output torque 515in lbs. At approx 172 rpm. I wired my setup with fwd and rev and can cold start with the hopper full.

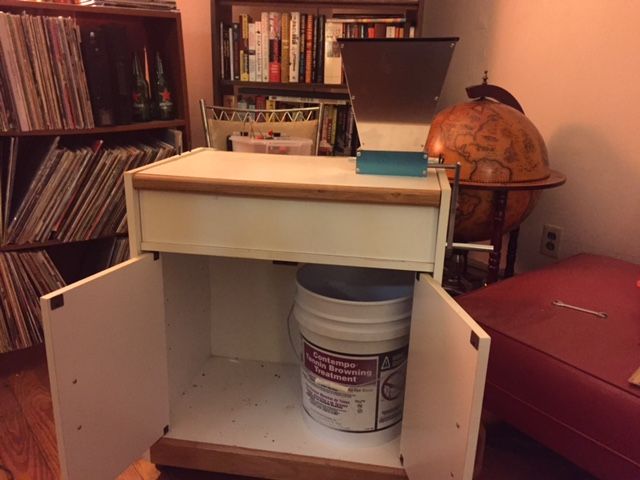

Monster mill mounted to stainless table for combo milling, weighing, and storage center.

View attachment 320939

View attachment 320940

View attachment 320937

View attachment 320938

https://www.homebrewtalk.com/showthread.php?t=373083&page=8

You win. Close the thread.

Monster mill mounted to stainless table for combo milling, weighing, and storage center.

View attachment 320939

View attachment 320940

View attachment 320937

View attachment 320938

https://www.homebrewtalk.com/showthread.php?t=373083&page=8

Monster mill mounted to stainless table for combo milling, weighing, and storage center.

View attachment 320939

View attachment 320940

View attachment 320937

View attachment 320938

https://www.homebrewtalk.com/showthread.php?t=373083&page=8

Here is my simple electric grain mill.

The table was an aborted bar stool bench project I did for my keezer.

The table was an aborted bar stool bench project I did for my keezer.You definitely win the most unique / interesting and probably "most compact" award!

Are those 1" rollers in that mill?? Give us the scoop on the motor you're using, too!

Adam

My mill is raised 2 3/4" and my motor is raised 1/4" for a grand total of 2 1/2". Pretty sure mine shipped out of Colorado.