You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Motorized Grain Mills: Time to show them off!

- Thread starter SAMPLER

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Here is mine. A little unsteady I'm afraid of an accident so I'm looking to get a cart of something for ease of use and ability to swap out the buckets when it gets full. 10gal batches often require more grain than will fit into one bucket..

TD

Oh, I cut the bottom off a plastic 5 gal water bottle and friction fit the neck through the hole on top of the hopper for feeding grain through.

I forget the revs per minute. I think it's around 300 rpm. Thought I read somewhere that was ideal speed. I get about 80% efficiency with this mill on my system.

TD

Oh, I cut the bottom off a plastic 5 gal water bottle and friction fit the neck through the hole on top of the hopper for feeding grain through.

I forget the revs per minute. I think it's around 300 rpm. Thought I read somewhere that was ideal speed. I get about 80% efficiency with this mill on my system.

What's the new track car??

TD

The new car is an E30 M3 chassis with an S54 in it. A friend of mine in Austin is doing the install currently but it is taking forever. The car should be a beast in theory when it's done. I run with my local Corvette club and they kick my ass routinely so this should help a bit...

total motor n00b here. Is a geared motor what I need if I don't want to use sheaves/pulleys? What do I look for in a geared motor? I'm also toying around the idea of using a harbor freight drill, but the pics in this post look too nice not to build one. I appreciate any help.

- Joined

- Mar 12, 2007

- Messages

- 6,841

- Reaction score

- 858

30 in-lbs minimumWhat do I look for in a geared motor?

150-300 RPM

Continuous Duty

m00se said:total motor n00b here. Is a geared motor what I need if I don't want to use sheaves/pulleys? What do I look for in a geared motor? I'm also toying around the idea of using a harbor freight drill, but the pics in this post look too nice not to build one. I appreciate any help.

When I was looking around, I thought that the gear motors available were significantly more expensive, even when you add the cost of the sheaves, which were not cheap either. The 1/2 HP appliance motors are relatively common and cheap, and are overkill for crushing grain. I understand the concern of using sheaves and a 1/2 HP motor turning the big sheave and the danger that poses.

I think the drill idea results in too much rpm on the mill, and probably impossible to dial in the rpm by hand on a reproducible basis. That being said, I did it for a while until I was able to finish my motorization and it worked. I don't really have any recollection of how good or bad my efficiency was back then, as I had other equipment problems that lead to poor efficiency, unrelated to the crush.

I bought all my parts through grainier I believe, (probably why they were $$). I couldn't seem to find the sheaves and related parts on McMaster or elsewhere.

Good luck.

TD

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

TrickyDick said:When I was looking around, I thought that the gear motors available were significantly more expensive, even when you add the cost of the sheaves, which were not cheap either. The 1/2 HP appliance motors are relatively common and cheap, and are overkill for crushing grain. I understand the concern of using sheaves and a 1/2 HP motor turning the big sheave and the danger that poses.

I think the drill idea results in too much rpm on the mill, and probably impossible to dial in the rpm by hand on a reproducible basis. That being said, I did it for a while until I was able to finish my motorization and it worked. I don't really have any recollection of how good or bad my efficiency was back then, as I had other equipment problems that lead to poor efficiency, unrelated to the crush.

I bought all my parts through grainier I believe, (probably why they were $$). I couldn't seem to find the sheaves and related parts on McMaster or elsewhere.

Good luck.

TD

Keep your eyes open on eBay... I picked up a Baldor 10:1 Speed Reducer for $75 (retails for $300), and coupled it (using the right Lovejoy couplers) between a Monster Mill and a 1/3 up Dalton motor that I also pillaged from eBay. It all works like a charm!

jeepinjeepin

Well-Known Member

I'm looking to eventually build a 10:1 gear drive overdrive unit to drive a tach for my mill. Why? Because I have the tach and who else has a tach on their grain mill?

Huaco

Well-Known Member

...and who else has a tach on their grain mill?

I like the way you think!

The new car is an E30 M3 chassis with an S54 in it.[...]

Ooooh! Retro!

Cheers!

jeepinjeepin said:I'm looking to eventually build a 10:1 gear drive overdrive unit to drive a tach for my mill. Why? Because I have the tach and who else has a tach on their grain mill?

Uh oh... I can see it now... A Kal-inspired control panel for the grain mill... Tachometer, temp probes in the grain bed and hopper, amp and volt meter, humidity... Where's my drawing pad???

3/4" plywood should be more than sufficient. Just use common sense when putting it together. Use wide bases and box it off the make it stiff in all directions.

Just in case someone has some woodworking skills (looks like most of you do) and wants to build a sheave (pulley) for some reason, here's a good link:

http://woodgears.ca/bandsaw/wheels.html

The first part is pretty quick about building a pulley, then the rest is spent on building bandsaw wheels. /jd

jeepinjeepin

Well-Known Member

Namako said:Uh oh... I can see it now... A Kal-inspired control panel for the grain mill... Tachometer, temp probes in the grain bed and hopper, amp and volt meter, humidity... Where's my drawing pad???

This ain't any plain old car tach. It's a diesel test tach and it's pimp.

Hang Glider

Beer Drinker

So...you'll get to the first two or three blips (x100). I wonder if there's a way to re-calibrate to x10 for a little more "show"

jeepinjeepin

Well-Known Member

Hang Glider said:So...you'll get to the first two or three blips (x100). I wonder if there's a way to re-calibrate to x10 for a little more "show"

Yeah, I'm not gonna mess with it if its only gonna show ~30rpm. The plan is to build a 10x overdrive so it shows ~300rpm.

lpdjshaw

Well-Known Member

Here's mine:

After some help from DayTripper and inspiration from ClarnoBrewer I just got finished motorizing my AWESOME Rebel Brewer Mill. This thing is built like a tank and now thats it's powered it has no problem crushing grain!

Thanks to all who have provided me with inspiration and guidance!!

I know this is a year old thread but this is rad and I would love to get more details on this build if you're still out there. How'd you take the handle off and wire it, how'd you mount it? Any info would be greatly appreciated!

blefferd

Well-Known Member

Here is my set up, not motorized yet but set up for a drill. I used an old shipping crate, some casters from my kegorator and about $20 worth of hardware. I am satisfied with it and plan on painting it soon! Eventually I want to put a direct drive gear motor on it, which will require some modification.

I am planning my mill right now, and I have a question about the driven pulley. (on the mill) I can't find a 3/8" bore pulley any larger than 4" OD anywhere. But I see a lot of people in this thread with huge pulleys on their mills. Where are you guys getting them? Grainger has 9" OD (what I need) with 1/2" bore, is there some kind of shaft sleeve I can get to step it up?

You can shim down a larger ID bore to a 3/8" shaft easily.

Here ya go. They have a variety of 3/8' ones on this page.

http://www.mcmaster.com/#standard-sleeve-bearings/=mv3f9t

http://www.mcmaster.com/#standard-sleeve-bearings/=mv3f9t

Finally got around to getting a cart for the malt mill. Inexpensive steel cart from Amazon. Used the same wooden base I had it all mounted to. Now I can drop a bucket on the shelf below and swap in a new bucket when it gets full. Fairly sturdy on the cart. I have another shelf I might modify to fit around the hopper as act as a shelf and further stabilize the hopper. A final step will be to shim or bolt the wooden baseboard to the wire shelf to keep it from moving. So far hasn't been an issue.

TD

TD

BaldApe

Well-Known Member

I used sleeve bearings. I was lucky to find the right inside diameter and outside diameter, and improvised the rest.

drunkenmonk

Well-Known Member

Motorized Monster Mill MM3-20 with 1 HP gear motor.

https://www.homebrewtalk.com/f51/motorized-monster-mill-build-373083/

https://www.homebrewtalk.com/f51/motorized-monster-mill-build-373083/

Brezentski

Member

- Joined

- Jul 16, 2012

- Messages

- 7

- Reaction score

- 0

Finally got my mill done this past Father's Day!

lpdjshaw

Well-Known Member

Very nice! Motor and gear reducer details for those of us who are technically challenged?

Brezentski

Member

- Joined

- Jul 16, 2012

- Messages

- 7

- Reaction score

- 0

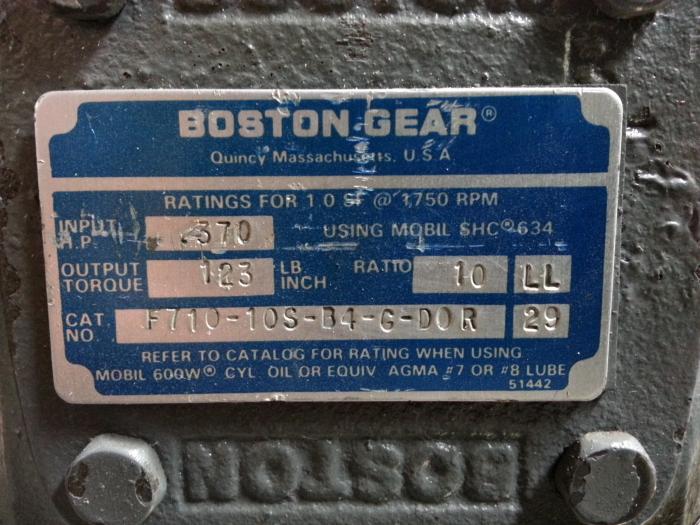

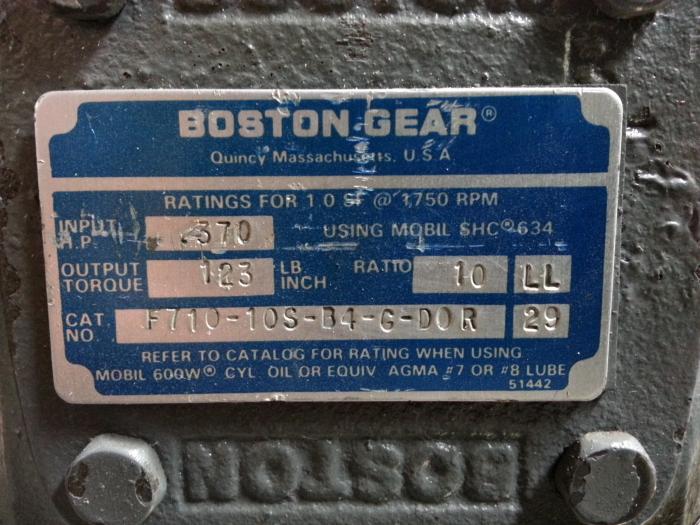

The Motor is 1/3 hp, turns 1725 rpms and the gear reduction is 10:1. Here are some pics.

bluedog_Brewing

Well-Known Member

I'm pretty sure that steppers motor require electronic commutation just like a brushless DC motor. If the motor has more than 2 or 3 wires, it usually requires an external controller to send pulses of power to each of the separate windings in the correct order and timing to run at a giving speed.

In other words, you cant apply a constant voltage and get a constant speed.

In other words, you cant apply a constant voltage and get a constant speed.

So... they get a signal from a computer (cnc controller) that tells it how many steps to take and how fast those steps need to be? Hmm... I bet there are some Sparky's out there that could make it work. I however, am not one.

jeepinjeepin

Well-Known Member

bluedog_Brewing said:I'm pretty sure that steppers motor require electronic commutation just like a brushless DC motor. If the motor has more than 2 or 3 wires, it usually requires an external controller to send pulses of power to each of the separate windings in the correct order and timing to run at a giving speed.

In other words, you cant apply a constant voltage and get a constant speed.

Correct. Someone explained it to me on here, maybe earlier in this thread. They need switched polarity on pairs on wires to move in steps.

Similar threads

- Replies

- 0

- Views

- 338

- Replies

- 7

- Views

- 849

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)