1brewerswife

New Member

Ok, trying to figure out how to motorize hubby's Valley Mill, I am electrically challenged, so reading all of the other posts blows my mind. I have a couple options at my disposal:

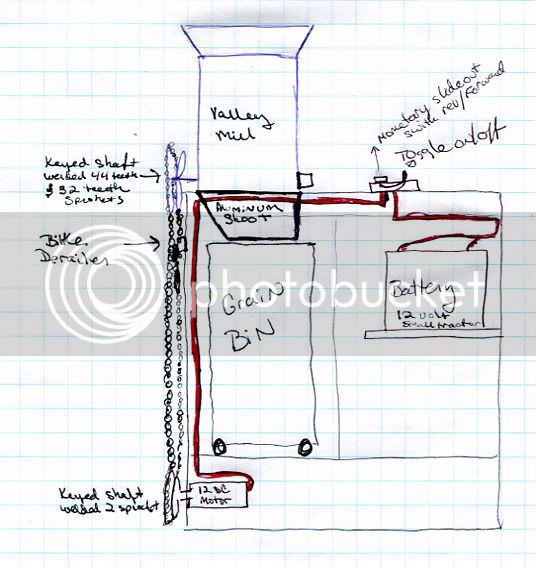

His valley mill has a 300 rpm MAX, I will be mounting it to a large cabinet that will also include grain storage (he will jump for joy on that alone). I will also be forming the shoot thru it to minimize dust to the pail. Here is what I have,

Two motors don't know what could possibly work-

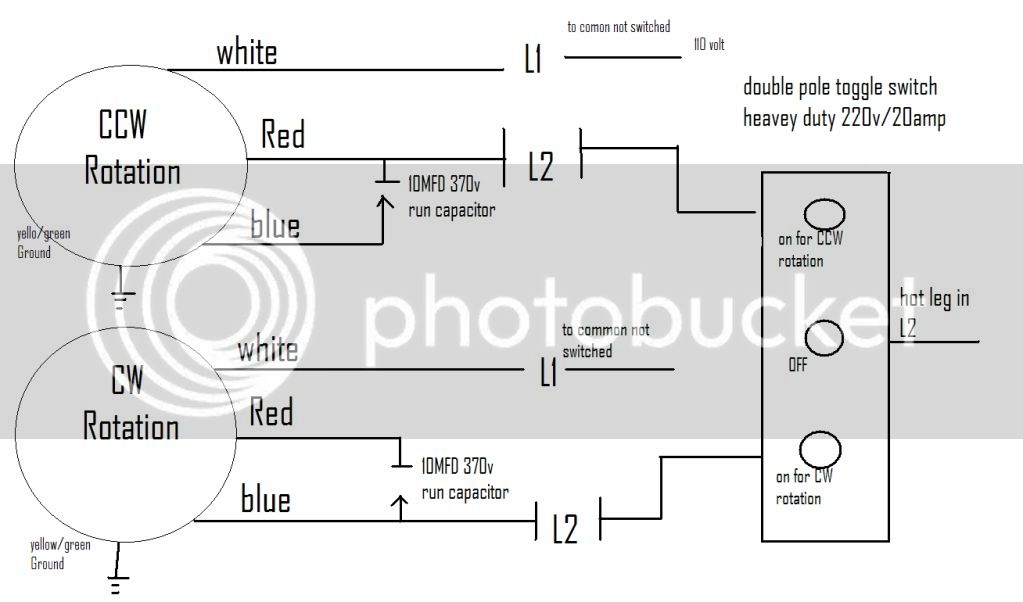

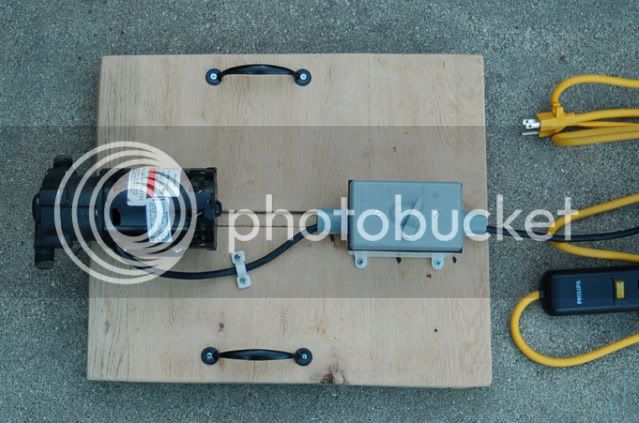

-Heavy duty trailer lift motor with LOTS of torque, 18 to 1 Ratio, Max 30 amp, 12 VDC, so would have to either find someone to convert into AC or just hook to battery with switch for reverse and on/off.

-Lathe motor - 4 speed with V-belts, spindle runs 60 HZ, Motor 350W, 1400rpm, AC120v, 60HZ swing, mounting into a great headstock (already enclosed) but it is a cheap lathe and the speeds are changed by hand moving belts on the two pulley's in headstock.

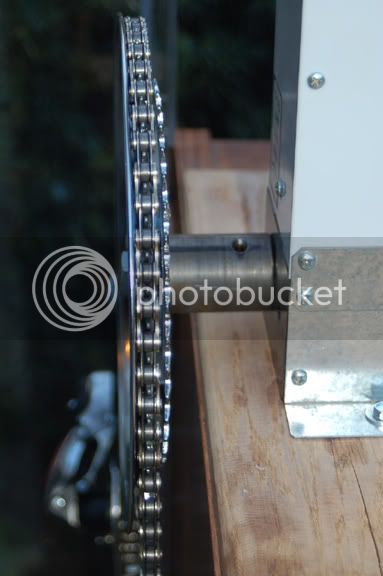

So after researching looking at pics, brainstorming with passersby on the street.....Now lost too much info...had seen a post, of course can't find now where someone took old bike apart and used the chain and gears to attach to a motor...tryed that on an old bike, but all was welded to mounts so won't work. I do have a local company that has lots of different gears, chains, vbelts etc, but would either of these motors work to even attempt this? I don't know what kind of torque the lathe motor would have, but the trailer lift motor really does, just really slow, that's why I was thinking of the bike sprockets and chain to keep torque just speed it up a little bit....hubby's bday is in 1 week....quick suggestions would be appreciated as any mathmatical or electrical calculations are nearly impossible for me. I don't know what all the rpms/HZ/Amp things mean, just writing what's on the equipment....baby talk needed. HA

too much info...had seen a post, of course can't find now where someone took old bike apart and used the chain and gears to attach to a motor...tryed that on an old bike, but all was welded to mounts so won't work. I do have a local company that has lots of different gears, chains, vbelts etc, but would either of these motors work to even attempt this? I don't know what kind of torque the lathe motor would have, but the trailer lift motor really does, just really slow, that's why I was thinking of the bike sprockets and chain to keep torque just speed it up a little bit....hubby's bday is in 1 week....quick suggestions would be appreciated as any mathmatical or electrical calculations are nearly impossible for me. I don't know what all the rpms/HZ/Amp things mean, just writing what's on the equipment....baby talk needed. HA

His valley mill has a 300 rpm MAX, I will be mounting it to a large cabinet that will also include grain storage (he will jump for joy on that alone). I will also be forming the shoot thru it to minimize dust to the pail. Here is what I have,

Two motors don't know what could possibly work-

-Heavy duty trailer lift motor with LOTS of torque, 18 to 1 Ratio, Max 30 amp, 12 VDC, so would have to either find someone to convert into AC or just hook to battery with switch for reverse and on/off.

-Lathe motor - 4 speed with V-belts, spindle runs 60 HZ, Motor 350W, 1400rpm, AC120v, 60HZ swing, mounting into a great headstock (already enclosed) but it is a cheap lathe and the speeds are changed by hand moving belts on the two pulley's in headstock.

So after researching looking at pics, brainstorming with passersby on the street.....Now lost

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)