I'm still a nube, I'm only 4 years into the hobby, I try to brew 2 -3 times a month, my latest step "up" is to grind my own grain.

So last Saturday, I took delivery of a Monster MM 3 G mill, originally , I had planned on using an electric drill ,milling over a bucket, upon reflecting, I got to thinking how arkeic this is and the potential for disaster real.

I decided to build a dedicated cabinet with a gear reduction motor.

after looking for motors on McMaster

Carr, Grainger, MSC and first electric motor, I settled on a 250 watt ,170 rpm variable speed gear motor on Amazon for $125, made in China, but so is the one Monster offers for almost $400.

The cabinet is 2x4 construction, 30: tall, 20" deep, 40" wide, fabricated with water proof glue and #20 biscuits and left over scrap lumber from my boat build .

The top is 2x6 pine "butcher block" construction.

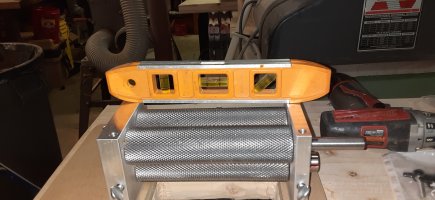

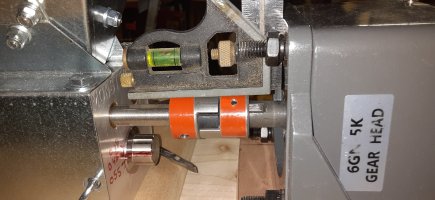

The mill was mounted on the factory platform,then bolted to the top then leveled fore and aft, shimmed as needed, the motor mounted in a similar manner, coupler on the mill is .50" bore, the motor requires 15mm bore, they share a common spider.all purchased from McMaster Carr

I set the gap to .040," and marked the setting with a sharpie, a note on this, when adjusting the gap, the adjuster on the drive side is turned CLOCKWISE, to close the gap,the gap is adjusted on the opposite end by turning COUNTER CLOCKWISE,these adjusters are on an eccentric cam, if adjusted the wrong way, the larg gap will be bigger at one end than the other and will not feed properly ,adjustments are made on the driven roller..

Speed was measured with a hand held tachometer, ( and noted, %70 is 200 rpm, no.load) the picture is poor, it's for illustration only, I wasnt aiming at the reflective strip when I took the picture

I still need to finish the door,storage shelves on the right side and paint.

The grain chute was fabricated from a forced hot air duct and length of ventilation hose, the "funnel " is sealed with 1/2" × 1/4" weather strip foam and screwd down with # 10 ×1/2" pan gmhead screws.

The cabinet will be ventilated via a 3" x3," axial fan with a 24x12x1 merv 8 filter,hopefully I finish tomorrow so I can grind grain and brew Saturday. ( the paint may wait )

So last Saturday, I took delivery of a Monster MM 3 G mill, originally , I had planned on using an electric drill ,milling over a bucket, upon reflecting, I got to thinking how arkeic this is and the potential for disaster real.

I decided to build a dedicated cabinet with a gear reduction motor.

after looking for motors on McMaster

Carr, Grainger, MSC and first electric motor, I settled on a 250 watt ,170 rpm variable speed gear motor on Amazon for $125, made in China, but so is the one Monster offers for almost $400.

The cabinet is 2x4 construction, 30: tall, 20" deep, 40" wide, fabricated with water proof glue and #20 biscuits and left over scrap lumber from my boat build .

The top is 2x6 pine "butcher block" construction.

The mill was mounted on the factory platform,then bolted to the top then leveled fore and aft, shimmed as needed, the motor mounted in a similar manner, coupler on the mill is .50" bore, the motor requires 15mm bore, they share a common spider.all purchased from McMaster Carr

I set the gap to .040," and marked the setting with a sharpie, a note on this, when adjusting the gap, the adjuster on the drive side is turned CLOCKWISE, to close the gap,the gap is adjusted on the opposite end by turning COUNTER CLOCKWISE,these adjusters are on an eccentric cam, if adjusted the wrong way, the larg gap will be bigger at one end than the other and will not feed properly ,adjustments are made on the driven roller..

Speed was measured with a hand held tachometer, ( and noted, %70 is 200 rpm, no.load) the picture is poor, it's for illustration only, I wasnt aiming at the reflective strip when I took the picture

I still need to finish the door,storage shelves on the right side and paint.

The grain chute was fabricated from a forced hot air duct and length of ventilation hose, the "funnel " is sealed with 1/2" × 1/4" weather strip foam and screwd down with # 10 ×1/2" pan gmhead screws.

The cabinet will be ventilated via a 3" x3," axial fan with a 24x12x1 merv 8 filter,hopefully I finish tomorrow so I can grind grain and brew Saturday. ( the paint may wait )

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)