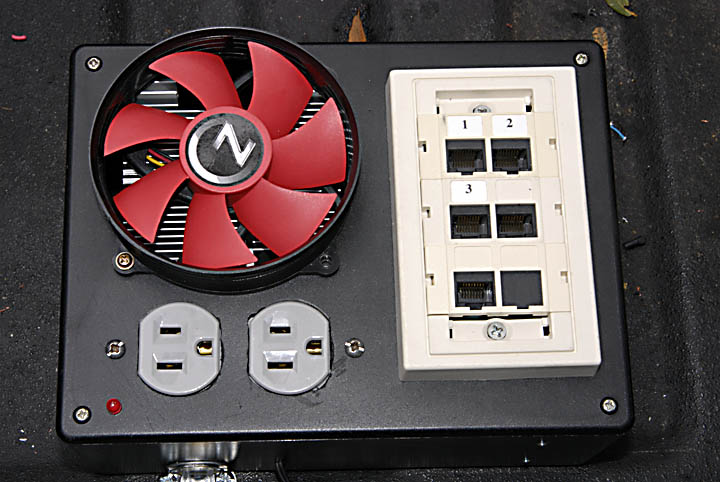

RJ-12 6x6 - that's what the USB plug uses, so I kept it consistent throughout. My wiring follows the Dallas Semiconductor pinout, so off the shelf components should be plug and play.

The system is now slightly more accurate, giving me decent results up to around 180ºF. The sensors still fall short as temps approach boiling.

The system is now slightly more accurate, giving me decent results up to around 180ºF. The sensors still fall short as temps approach boiling.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)