sashurlow

Well-Known Member

Hey all,

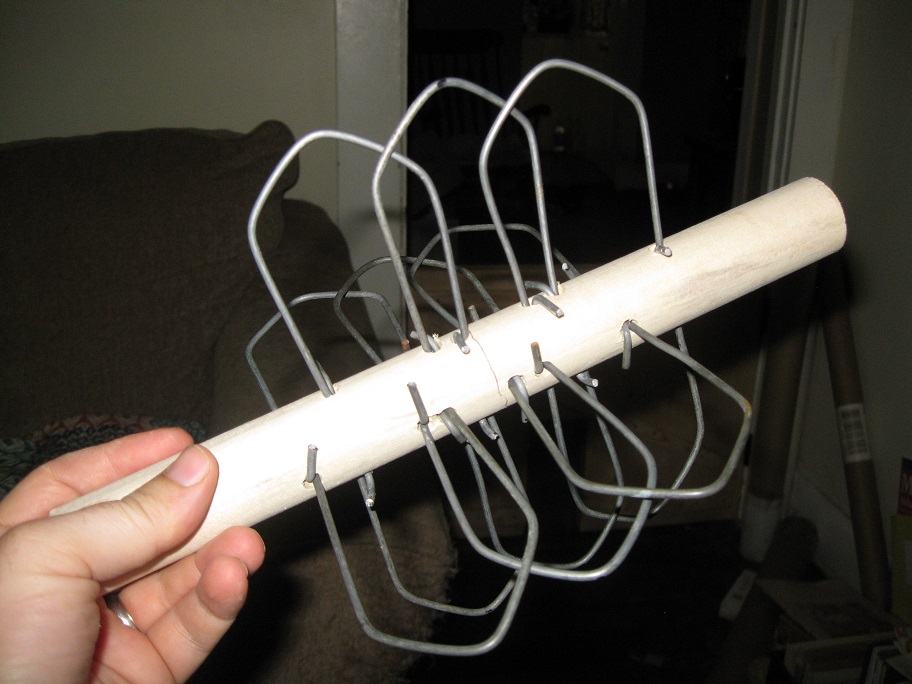

I just read a post about a hops picking machine and noticed that all the posts are for a small farm. GVH Dan mentioned prototyping one based off of a hand drill. Has anyone attempted to make something small, cheap and simple for the hobby grower? Last year I was dreading picking so much that I wasted most my harvest, and I only have 8 plants.

Based on what I have seen, mostly Dan's work, it would be pretty simple to make one out of plywood that is 6-8 inches wide. What are the secrets to picking fingers?

I just read a post about a hops picking machine and noticed that all the posts are for a small farm. GVH Dan mentioned prototyping one based off of a hand drill. Has anyone attempted to make something small, cheap and simple for the hobby grower? Last year I was dreading picking so much that I wasted most my harvest, and I only have 8 plants.

Based on what I have seen, mostly Dan's work, it would be pretty simple to make one out of plywood that is 6-8 inches wide. What are the secrets to picking fingers?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)