You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mash Tun Pictures

- Thread starter BonzoAPD

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Here's an old one. The false bottom is the same, but I've replaced the return (sparge) arm with a Mash Return kit from Bobby M over at BrewHardware.com (love it!). I use a RIMS setup and it works great. Before the RIMS setup, I used a 10 gallon rubbermaid cooler with the braid. Don't really have anything bad to say about it either, but I wanted a better way of maintaining the mash temps, so I later went with the RIMS. I also wrap it with water heater insulation during the mash.

http://brewhardware.com/accessories/114-mashtube

http://brewhardware.com/accessories/114-mashtube

I use a rectangular 48 quart cooler with a stainless steel braid. I cover the braid with a voile cloth sock (or boiled panty hose) to help filter the grain. I have never had a stuck sparge and I get clear runnings for the wort right from the start.

hillbillyjones

Well-Known Member

I use the 10 gallon orange rubbermaid beverage cooler from Home Depot. I got the stainless valve and parts from bargainfittings.com. I got a "bazooka" screen from them too. They call it a kettle screen. Id go with their " mash braid". The kettle screen is fine but a little too long and its stiff so its harder to get flat on the bottom of the cooler.

Ive only got 4 batches done and i like the setup. I do batch sparge and get 2 degree temp drop over an hour.

Why a fabric filter over the screen?

Ive only got 4 batches done and i like the setup. I do batch sparge and get 2 degree temp drop over an hour.

Why a fabric filter over the screen?

My ss braid did not filter out some of the finer grain particles during the vorlauf stage where I had to draw 6 quarts to get clear runnings of the wort. I use material left over frm making brew in a bag sacks. It filters the grain with the braid supporting mash weight just fine.

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

I use a basic, round cooler for mashtun, with a spigot and screen. Photos here http://www.singingboysbrewing.com/about.html

Can you post pictures of your mash tuns? I am in the process of planning mine and would love to see some more ideas.

I won't use plastic for a mash tun anymore. Stainless only for me.

Saved the expense of a false bottom which never seem to work that great, the braided strainer works great in the mash tun and is easy to clean. No stuck mashes.

http://www.homebrewstuff.com/15-gallon-kettle-w-valve-thermometer.html

http://www.homebrewstuff.com/30-hop-strainer-with-kettle-adapter.html

I got the 5 gallon cooler from work for free because the valve leaked, originally bought a false bottom that was a bit too big so ended up keeping the fittings off of it, and making a nice false bottom from an aluminum pizza pan. If you do a search you can find threads on HBT about how to do all this. Anyway it works great, fly sparging with it as I'm typing this actually, oh and yes I named it "Spanky".

WPStrassburg

Well-Known Member

GoodDogShelby

Well-Known Member

Here's mine. A 10 gallon industrial Igloo with a false bottom. I added a loc-line recirc return line with a cam lock fitting.

biertourist

Well-Known Member

I just realized I never uploaded pics of mine to the interwebs (i'll have to get on that tonight...).

View of False bottom

Generic top view of mashtun

Here's a picture of my hand drawn design of the bottom drain; the very top and very bottom images are my sketches of the 1 1/2" tri clamp ferrule option and the middle (option 2) drawing was when I was considering welding in a camlock fitting as a bottom drain (I'm glad I went with the tri clamp; for the record).

I'm using a 13.2 gallon double walled, insulated stainless mashtun. It's made by a German/French company who sells them through their Ebay Germany store; they refuse to ship directly to the US, though so you need a european intermediary to ship through. (I lived in Ireland so I got lucky.)

The picture isn't mine but one that is very much similar to mine. I had a bottom draining 1 1/2" triclamp fitting welded in, unlike the weldless fitting in the picture.

The false bottom was simply a sheet of perforated 304 stainless 0.06" thick with 0.09375" diameter holes and a 0.15625 close stagger (16x16") -we then cut it into a circle with a plasma cutter and ground it down on a bench grinder to get it to fit. I then just used stainless bolts and nuts to stand it off of the bottom slightly less than 1/2".

It results in a 1:1 height to width ratio for 10 gallon mashes (no stuck mashes for me even while constantly recirculating at a pretty good speed) and a 1:2 height to width ratio for 5 gallon mashes. (Slightly cloudy wort but REALLY fast and stick-free mashes.)

It definitely smoked a lot while welding it as the heat started burning the insulation inside; my welder didn't really know what he was doing and getting a hole big enough into this thing was a HUGE PITA as it wouldn't fit on a drill press...

It holds temp like nobody's business.

I designed it for brain-dead english style single infusion mashes and with the idea that I'd want to eventually move to HERMS. The insulation means that all the heat I get from my HERMS coil goes to quickly ramping up my temp (very little lost heat) and the high width to height ratio means that I don't have to worry about getting a stuck mash; being able to recirculate at a faster rate means that the liquid comes out of the HERMS coil at a lower temp and doesn't damage my enzymes as much while they're at their hottest either.

VERY happy with my design and equipment; but very unhappy with my welder.

Adam

View of False bottom

Generic top view of mashtun

Here's a picture of my hand drawn design of the bottom drain; the very top and very bottom images are my sketches of the 1 1/2" tri clamp ferrule option and the middle (option 2) drawing was when I was considering welding in a camlock fitting as a bottom drain (I'm glad I went with the tri clamp; for the record).

I'm using a 13.2 gallon double walled, insulated stainless mashtun. It's made by a German/French company who sells them through their Ebay Germany store; they refuse to ship directly to the US, though so you need a european intermediary to ship through. (I lived in Ireland so I got lucky.)

The picture isn't mine but one that is very much similar to mine. I had a bottom draining 1 1/2" triclamp fitting welded in, unlike the weldless fitting in the picture.

The false bottom was simply a sheet of perforated 304 stainless 0.06" thick with 0.09375" diameter holes and a 0.15625 close stagger (16x16") -we then cut it into a circle with a plasma cutter and ground it down on a bench grinder to get it to fit. I then just used stainless bolts and nuts to stand it off of the bottom slightly less than 1/2".

It results in a 1:1 height to width ratio for 10 gallon mashes (no stuck mashes for me even while constantly recirculating at a pretty good speed) and a 1:2 height to width ratio for 5 gallon mashes. (Slightly cloudy wort but REALLY fast and stick-free mashes.)

It definitely smoked a lot while welding it as the heat started burning the insulation inside; my welder didn't really know what he was doing and getting a hole big enough into this thing was a HUGE PITA as it wouldn't fit on a drill press...

It holds temp like nobody's business.

I designed it for brain-dead english style single infusion mashes and with the idea that I'd want to eventually move to HERMS. The insulation means that all the heat I get from my HERMS coil goes to quickly ramping up my temp (very little lost heat) and the high width to height ratio means that I don't have to worry about getting a stuck mash; being able to recirculate at a faster rate means that the liquid comes out of the HERMS coil at a lower temp and doesn't damage my enzymes as much while they're at their hottest either.

VERY happy with my design and equipment; but very unhappy with my welder.

Adam

biertourist

Well-Known Member

I should also state that these "thermo box" mashtuns, as the UK and Ireland guys call them, are so ridiculously reasonably priced that you wouldn't even believe it.

The hard part is in getting them shipped to the US and cutting them and installing anything in them.

They sell much bigger ones than the 50L one that I bought and they're all VERY reasonably priced. A lot of the JimsBeerKit.co.uk guys build entire 3 vessel electric breweries out of them. -Because they have 240v power at the wall with built in gfci-like breakers they make the most simple, cheap, and energy-efficient electric breweries available. (Install a tea kettle electric element into the HLT and one into the boil kettle and plug them in directly to the wall with a computer power cord.) -You've got a direct-heated electric brewery that's fully insulated and still exposes beautiful stainless to the outside. You can set it on any sort of stand as the outside doesn't even get hot to the touch after an hour boil. (No SSR and control panel necessary; for the boil kettle you can install 2 elements and just unplug the 2nd one once you get up to a boil so you get to boil faster.)

Their weakness is that they're VERY difficult to weld so most everyone goes with weldless fittings which on these can leak into the inner insulation layer and you're in the same place as a cooler box mashtun conversion. (funky infection in the inner insulation layer). Each layer is pretty thin stainless so that makes welding even more difficult. (Don't let anyone even ATTEMPT it without a heat sink.)

IMHO, they're VERY hard to beat if your ok with a weldless option and are handy and have plenty of tools; AND you're willing to deal with customs and importing them. (My only mistake was going with a sketchy "welder".)

Personally I wouldn't use one as a boil kettle but for an HLT and a mashtun they're great.

Adam

The hard part is in getting them shipped to the US and cutting them and installing anything in them.

They sell much bigger ones than the 50L one that I bought and they're all VERY reasonably priced. A lot of the JimsBeerKit.co.uk guys build entire 3 vessel electric breweries out of them. -Because they have 240v power at the wall with built in gfci-like breakers they make the most simple, cheap, and energy-efficient electric breweries available. (Install a tea kettle electric element into the HLT and one into the boil kettle and plug them in directly to the wall with a computer power cord.) -You've got a direct-heated electric brewery that's fully insulated and still exposes beautiful stainless to the outside. You can set it on any sort of stand as the outside doesn't even get hot to the touch after an hour boil. (No SSR and control panel necessary; for the boil kettle you can install 2 elements and just unplug the 2nd one once you get up to a boil so you get to boil faster.)

Their weakness is that they're VERY difficult to weld so most everyone goes with weldless fittings which on these can leak into the inner insulation layer and you're in the same place as a cooler box mashtun conversion. (funky infection in the inner insulation layer). Each layer is pretty thin stainless so that makes welding even more difficult. (Don't let anyone even ATTEMPT it without a heat sink.)

IMHO, they're VERY hard to beat if your ok with a weldless option and are handy and have plenty of tools; AND you're willing to deal with customs and importing them. (My only mistake was going with a sketchy "welder".)

Personally I wouldn't use one as a boil kettle but for an HLT and a mashtun they're great.

Adam

Brewski1975

Well-Known Member

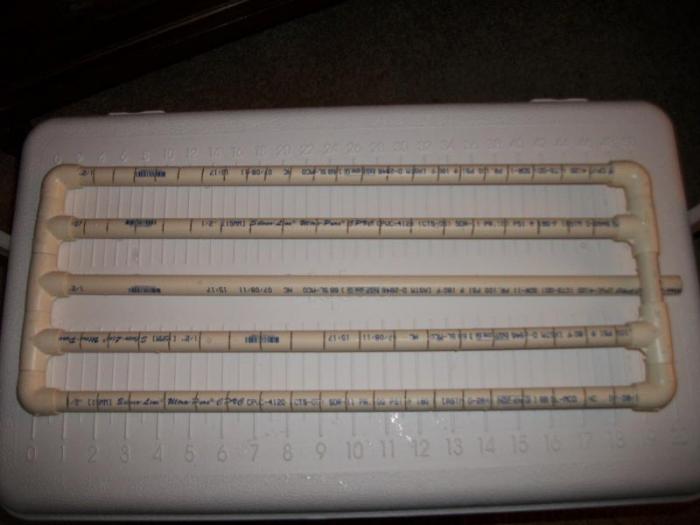

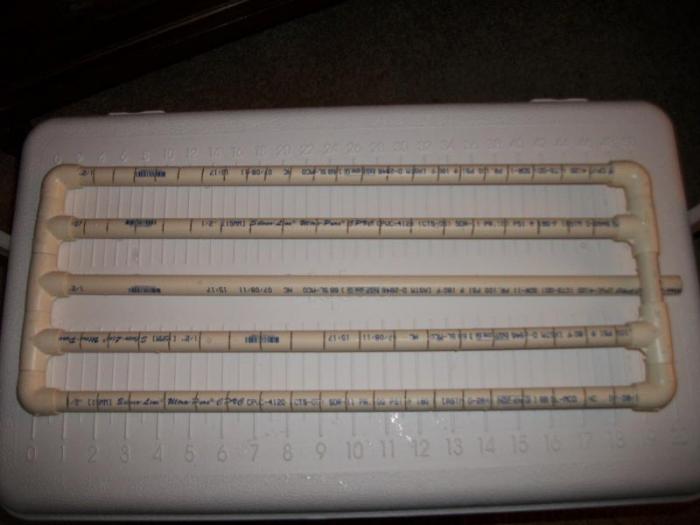

I use a 48 qt mash tun using a cpvc manifold. After fine tuning everything I average about 80% efficiency

tnlandsailor

Well-Known Member

The rectangular coolers are a really nice option for mash tuns. They tend to be the cheapest of the coolers and they are a very nice size. Even the smallest of the standard size is 48 quarts which is significantly larger than the 10 gallon round ones. This helps a lot when trying to get higher gravities or brewing larger batches. They are also easy to fit with slotted manifolds.

Here is a write up I did on my mash tun construction

Another nice thing about rectangular coolers is that you can find interesting sizes if you keep your eyes open, even when you aren't really shopping for a new mash tun. I got my current 60 quart model at Sears at an end of the season sale. The extra few gallons in this one makes 12 gallon batches very easy to deal with. I also picked up a 72 quart cooler at Costco earlier this year. While this is probably bigger than most brewers would need, it opens up a lot of options for higher gravity large batches. It just depends on the type of brewing that you will be doing.

Here is a write up I did on my mash tun construction

Another nice thing about rectangular coolers is that you can find interesting sizes if you keep your eyes open, even when you aren't really shopping for a new mash tun. I got my current 60 quart model at Sears at an end of the season sale. The extra few gallons in this one makes 12 gallon batches very easy to deal with. I also picked up a 72 quart cooler at Costco earlier this year. While this is probably bigger than most brewers would need, it opens up a lot of options for higher gravity large batches. It just depends on the type of brewing that you will be doing.

Bill_in_VA

Well-Known Member

Here are some pics from the construction of mine, made from 54 qt handmedown igloo. Hope they help.

Initially I ran it slotted side up, but I've settled on slots down being better.

And a crappy cell pic of a mash....

Initially I ran it slotted side up, but I've settled on slots down being better.

And a crappy cell pic of a mash....

wilserbrewer

BIAB Expert Tailor

I used a 48 qt cooler for a while...very simple ghetto conversion, worked excellent! Less is more sometimes IMHO...cheers!

I dubbed it the "10 minute mash tun" based on how long the conversion takes...

https://www.homebrewtalk.com/f11/ten-minute-cooler-mash-tun-conversion-125108/

I dubbed it the "10 minute mash tun" based on how long the conversion takes...

https://www.homebrewtalk.com/f11/ten-minute-cooler-mash-tun-conversion-125108/

Similar threads

Latest posts

-

-

-

-

-

-

I just poured 42 bottles of HB Dunkelweizen down the drain

- Latest: madscientist451

-

-

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)