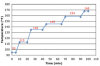

I received an article in my email from Craft Beer & Brewing called "The Battle of the BrewBots." I'm not personally that interested in automated brewing because I like being involved in all the steps ... hell I'd do my own malting if I could! BUT, I ran across this sentence, describing the BEERMKR machine: "Automatically brings your mash up to temperature in an extended step mash. This hits all of the enzyme activation temperatures along the way and produces 80% efficient mashes on average." I thought, well now that's different. So, hive mind: is there any advantage to this? Like, should I just heat my mash from room temp. up to mash temp and not worry about calculating strike temp?

The Beermkr machine is a machine which automatizes all the production. You put the grains in, and it makes mashing, boiling, and fermentation.

Regarding extended step mash though, it makes more or less what every automatic kettle (also known as "all in one" kettle, AIO, "brew in a pipe", BIAP etc.) can do: you can program the mash steps, the duration of each step, and the heat for the ramp to each next step.

I don't know about the Beermkr machine, but an AIO kettle would usually just employ a pump for wort recirculation.

In theory, you can program all the multi-step mashing, step by step.

The machine will beep and pause after the first step, to give you time to do the "dough in". Then you press a button to tell the machine to continue.

The machine will perform automatically all the steps at the various temperatures, and the ramp-up at the set wattage.

Then it will stop before the boiling step, to give you time to do the mash out and the sparging if you want. Then you press a button and the machine goes automatically to the boiling phase, ringing a bell for each (programmed) hop addition.

This is something that all AIO systems can do, from the expensive ones like the Braumeister to the inexpensive ones like mine.

Same people modify their kettle putting a smart PID controller in place of the stock controller.

The efficiency will not be better by programming the controller rather than by executing all the steps and the ramps manually, of course.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)