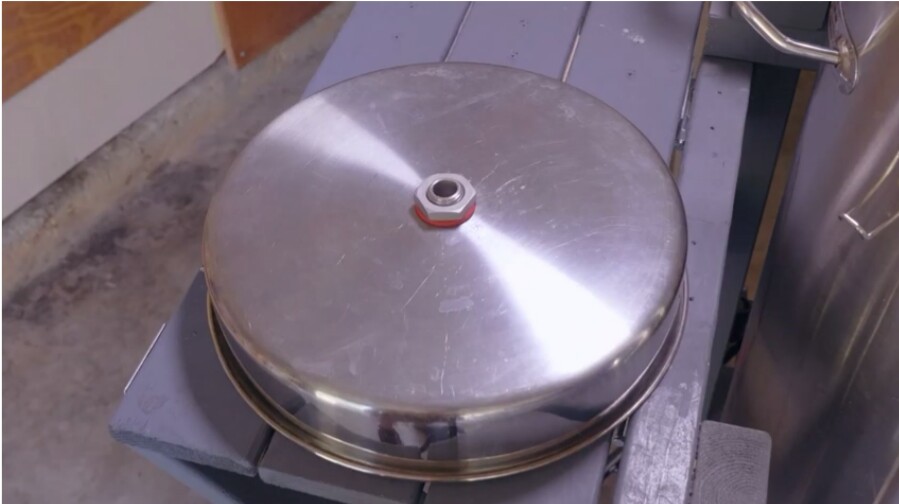

I think this one would be good.

https://www.webstaurantstore.com/vi...-qt-saute-pan-20-qt-stock-pot/473SSCOVR5.htmlOnce the lip is reworked you'd have just under 12" giving you 1/2" or so clearance which is pretty good for a mashcap. I know this brand and rebending the lip up is easy enough to do with just an adjustable wrench and about 1 hour of your time.

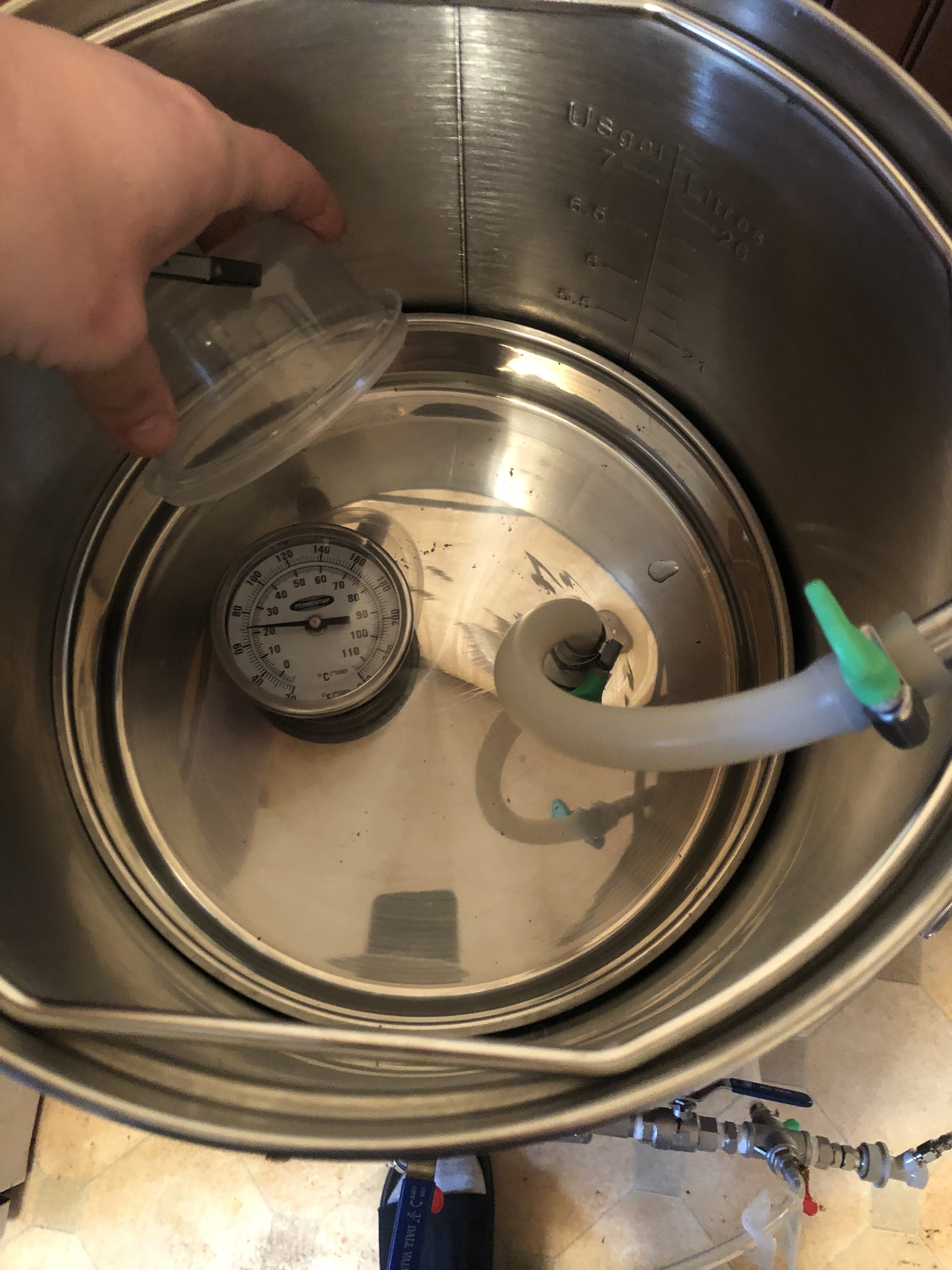

Here is a picture of the two caps of this brand I reworked. Both turned out nicely.

View attachment 682080

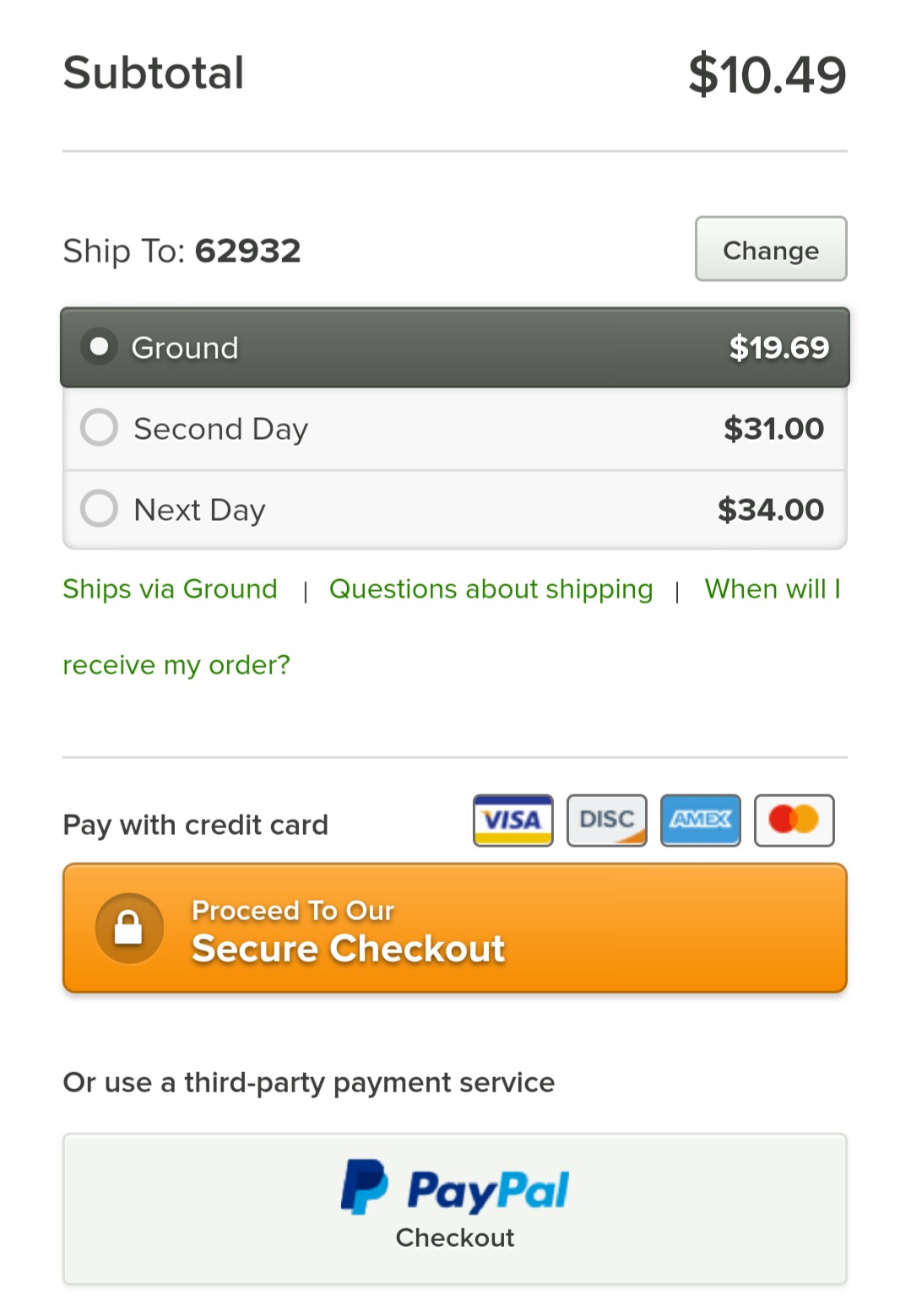

Good God man... They want nearly $20.00 to ship me $10.50 lid. Shipping skyrockets from there. I don't mind paying reasonable shipping costs. But I don't like it when a company profits from shipping also. It leaves a bad taste in my mouth. Like a over hopped beer.

There are a few home brew shops, like this also. That low ball their prices, then when you go to the cart and calculate shipping, you about fall out of your chair.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)