You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mash cap and re-circulation

- Thread starter JDXX1971

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Lots of restaurant supply stores with kettle lids and deep dish pizza pans etc. What is your cooler inside diameter?

13" or 33cm would be a tight fit. Thinking maybe something like 32 1/2cm or 12 3/4" maybe a little smaller, if it needed to float

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

Yeah, well, depends on how OC you are about fit. I've looked on and off for a couple of years for some SS baking or even pizza pan or the like that'd fit inside my 17-5/8" ID Blichmann 20g kettle without leaving a wide gap. I'm seriously thinking of having something fabricated at this point...

So far in our experience the Blichmann kettles are the hardest to find a good fit. They are just odd sized compared to commercial cookware.

This one here might fit.

https://www.webstaurantstore.com/vi...ment-lid-for-60-qt-stock-pot/473SSCOVR10.htmlI have two of the 14" ones and I know from doing it that the outer lip can be bent back to vertical reducing the OD by about an inch. Could be tight though.

Also this might work..

https://www.webstaurantstore.com/vollrath-3717c-17-3-4-centurion-domed-cover/9223717C.htmlHowever I have no actual experience rebending this brand cap and it also has a bead round the edge which complicates that job.

This one looks like it might work but maybe due to the shape could trap air.

https://www.webstaurantstore.com/vo...ss-steel-cover-with-loop-handle/92247779.htmlIt has no bead and so you should be able to rework that lip.

It's hard to know what the final size will be but some of these are cheap enough you could destroy one finding out and not be to much out of pocket.

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

13" or 33cm would be a tight fit. Thinking maybe something like 32 1/2cm or 12 3/4" maybe a little smaller, if it needed to float

I think this one would be good.

https://www.webstaurantstore.com/vi...-qt-saute-pan-20-qt-stock-pot/473SSCOVR5.htmlOnce the lip is reworked you'd have just under 12" giving you 1/2" or so clearance which is pretty good for a mashcap. I know this brand and rebending the lip up is easy enough to do with just an adjustable wrench and about 1 hour of your time.

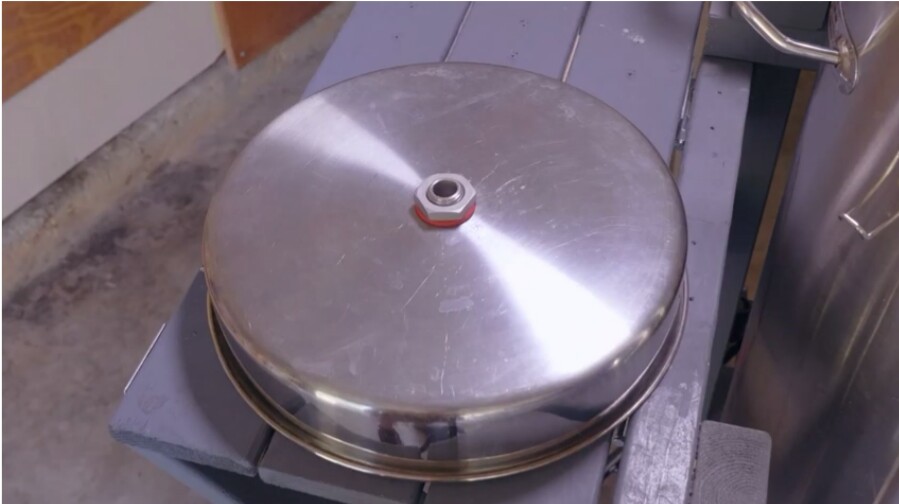

Here is a picture of the two caps of this brand I reworked. Both turned out nicely.

I had not considered trying to trim a stainless steel lid to fit.

Sounds hard core - thinking about my reciprocating saw chattering its way around trying to hold the diameter true

[edit] Now see the trick is in the bending, not cutting. Still, looking for something more turnkey if possible.

Speaking of caps...are there are any good examples incorporating an integrated recirculation return that doesn't plough up the grain bed?

Cheers!

Sounds hard core - thinking about my reciprocating saw chattering its way around trying to hold the diameter true

[edit] Now see the trick is in the bending, not cutting. Still, looking for something more turnkey if possible.

Speaking of caps...are there are any good examples incorporating an integrated recirculation return that doesn't plough up the grain bed?

Cheers!

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

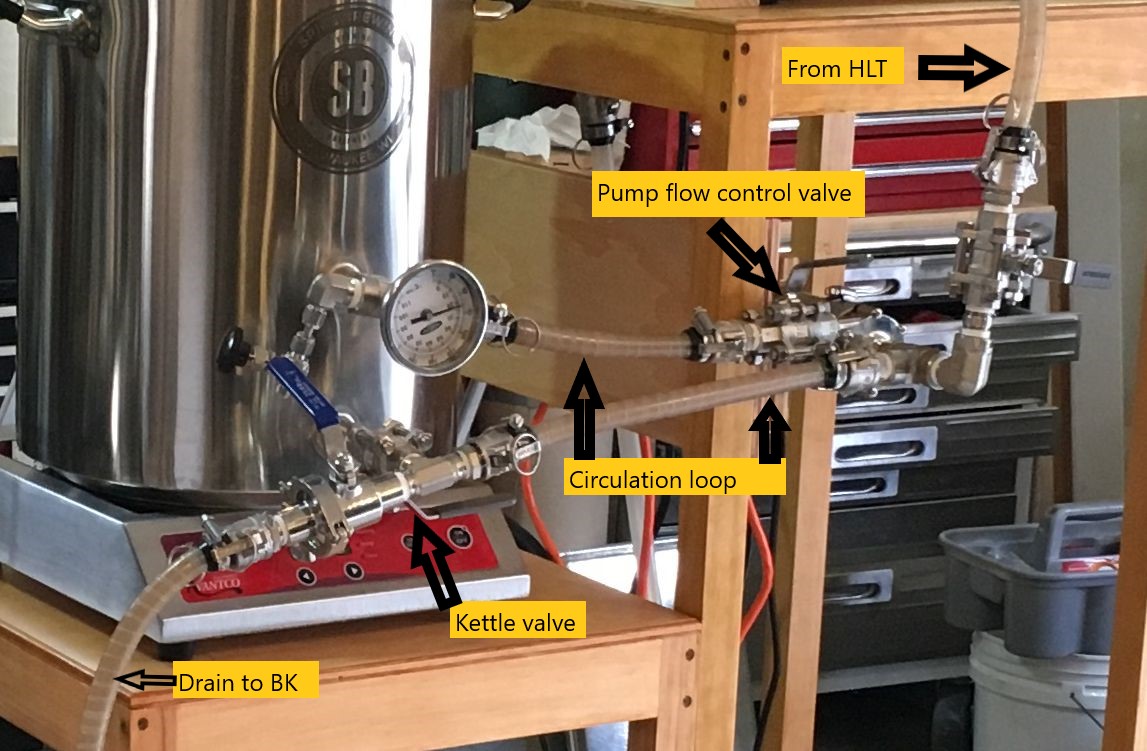

Yep I had the upper port spare which was threaded on both sides (Spike V3) so I just have a nipple going to the center then a 90 going up. I measured the height of my typical grain bed and measured so the coupler you see threaded on there is about 1.5" above the grain bed. The reason I use that 1/2" SS NPT to 3" TC is that I'm using it as a wide flange to rest my mashcap on. This way it is in place when I do the underlet and just floats up on the water level as it comes up. This is the way the cap looks before the underlet and cap float.Thanks @Bilsch!

I think I'll use your method... I have a spare port in the side!

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

Speaking of caps...are there are any good examples incorporating an integrated recirculation return that doesn't plough up the grain bed?

Lots of guys have drilled a hole in the cap and port the return through then use some kind of diffuser. The problem is that now you have added more weight to the mashcap and can easilly swamp it if the return hose isn't supported properly. Also long runs of silicone hose lose heat and increase your oxygen pickup through the hose. Best to keep recirc circuits short.

Dustin_J

Well-Known Member

Lots of guys have drilled a hole in the cap and port the return through then use some kind of diffuser. The problem is that now you have added more weight to the mashcap and can easilly swamp it if the return hose isn't supported properly. Also long runs of silicone hose lose heat and increase your oxygen pickup through the hose. Best to keep recirc circuits short.

View attachment 682084

How is that PTFE film tape on your hoses holding up - any issues at all?

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

How is that PTFE film tape on your hoses holding up - any issues at all?

Good so far going on about 1.5 year with the first application. Might need to be redone in another year or so.. we shall see.

I think this one would be good.

https://www.webstaurantstore.com/vi...-qt-saute-pan-20-qt-stock-pot/473SSCOVR5.htmlOnce the lip is reworked you'd have just under 12" giving you 1/2" or so clearance which is pretty good for a mashcap. I know this brand and rebending the lip up is easy enough to do with just an adjustable wrench and about 1 hour of your time.

Here is a picture of the two caps of this brand I reworked. Both turned out nicely.

View attachment 682080

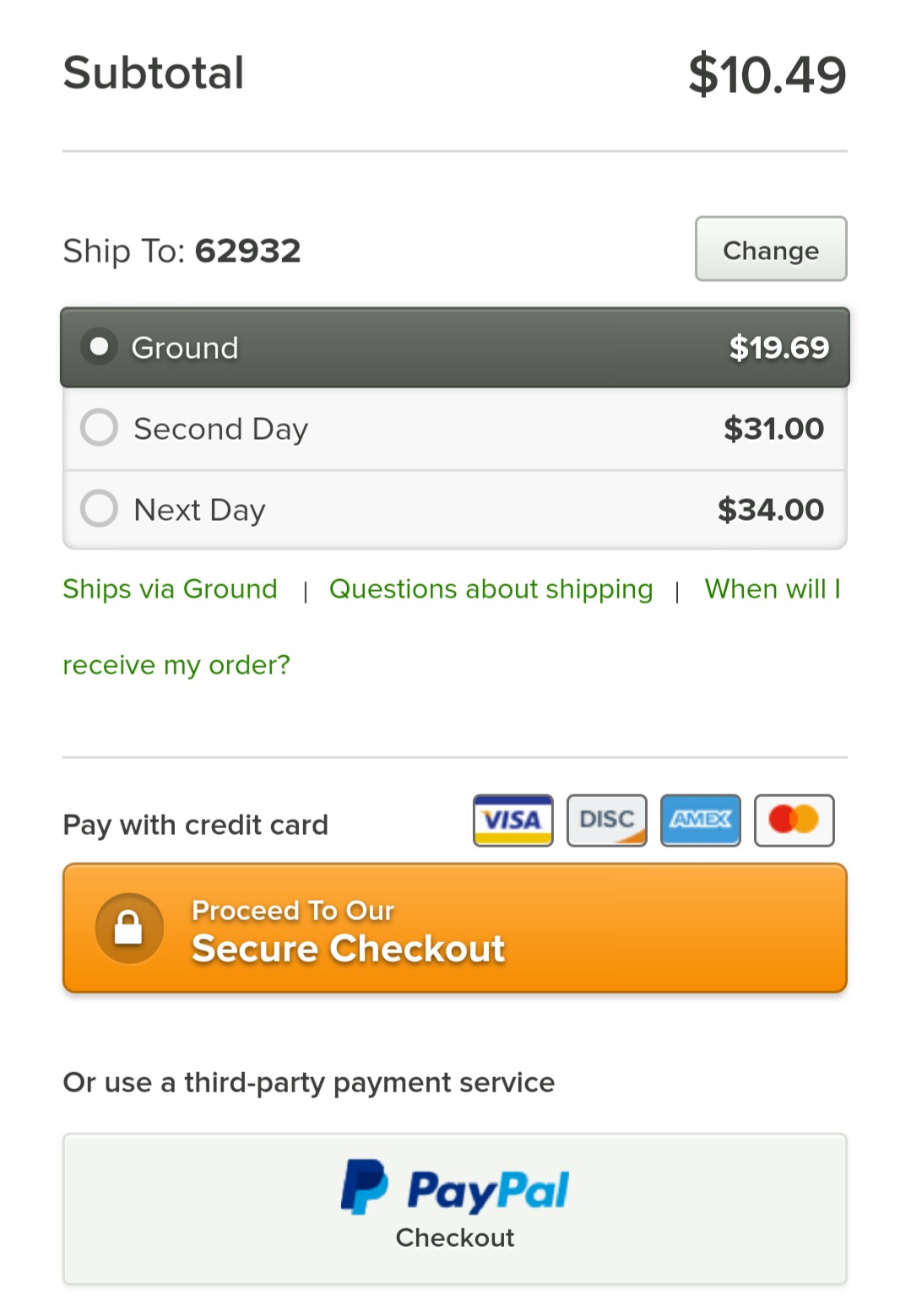

Good God man... They want nearly $20.00 to ship me $10.50 lid. Shipping skyrockets from there. I don't mind paying reasonable shipping costs. But I don't like it when a company profits from shipping also. It leaves a bad taste in my mouth. Like a over hopped beer.

There are a few home brew shops, like this also. That low ball their prices, then when you go to the cart and calculate shipping, you about fall out of your chair.

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

Good God man... They want nearly $20.00 to ship me $10.50 lid. Shipping skyrockets from there. I don't mind paying reasonable shipping costs. But I don't like it when a company profits from shipping also. It leaves a bad taste in my mouth. Like a over hopped beer.

Or you could think of it as a $25 lid with $5 shipping. But seriously at least this way you already know it's going to be bendable and will work for the purpose intended. Any other option.. you are taking a chance.

Last edited:

Or you could think of it as a $25 lid with $5 shipping. But seriously at least this way you already know it's going to be bendable and will work for the purpose intended. Any other option.. you are taking a chance.

I have a couple of questions/verifications if you don't mind. In order to properly manipulate said lid into a mash cap.

the mash cap, must have a flat bottom, to minimize the mash to O2.

It must be able to float freely without getting bound up on the sides of the MLT

The mash cap sides should be high enough to not allow swamping

Add LODO strike and sparge from the bottom of the MLT, with minimal splashing or exposure to O2

How do you handle lautering

or recirculation with a mash cap? Is it ok to drill a hole for a barb? I would think so as long as its not to heavy to swamp the lid.

I found this video fairly informative wrt a recirculation return line solution. May not be the best but it's a benchmark.

I'd be using my autosparge output, but pretty much same otherwise...

Cheers!

I'd be using my autosparge output, but pretty much same otherwise...

Cheers!

I found this video fairly informative wrt a recirculation return line solution. May not be the best but it's a benchmark.

I'd be using my autosparge output, but pretty much same otherwise...

Cheers!

Thanks for the video

These pictures from the video is what I plan on doing after I grind the welded handle off the lid. Try and make the barb sit dead center. I'll probably fabricate some type of stainless steel defuser so I don't tunnel into the grain bed when lautering/recirculating.

The idea in the video of the up-turned arm is pretty solid. I expect it will be a challenge to do much better, but I'd love to see other solutions just the same

Cheers!

Cheers!

The idea in the video of the up-turned arm is pretty solid. I expect it will be a challenge to do much better, but I'd love to see other solutions just the same

Cheers!

I fabricated a stainless steel sparge arm/defuser for my Rubbermaid cooler MLT. It believe I'll just do the same kind of thing for the bottom of the mash cap. I think it will work ok. Just need something to prevent tunneling into the grain bed.

Have you seen the 20 gallon water cooler? I want one to convert into MLT. I like my 10 gallon Rubbermaid MLT, it's very efficient I loose no more than 1/2 a degree mashing even over 90 minutes.

https://www.panchosbrewinglab.com/shop/Pancho’s-Keg-Kooler™-20-Gallon-Water-Cooler-p139190214

https://www.panchosbrewinglab.com/shop/Pancho’s-Keg-Kooler™-20-Gallon-Water-Cooler-p139190214

I saw one of those a number of years ago, thought some folks would go gaga over it, but it didn't seem to make as big an impact as I would have expected, given how many people complained about doing high gravity batches in a 10 gallon Rubbermaid (myself included  )

)

I don't know about the price being more than triple a 10g cooler though. Ouchie. Maybe that's the hold-back.

Your idea of an "anti-tunneling plate" for lack of a better description looks like it'd work, though I'd prefer it closer to the bottom of the cap, and perhaps wider. I had been thinking of a similar idea but hadn't fleshed it out that far, so thanks for that

Cheers!

I don't know about the price being more than triple a 10g cooler though. Ouchie. Maybe that's the hold-back.

Your idea of an "anti-tunneling plate" for lack of a better description looks like it'd work, though I'd prefer it closer to the bottom of the cap, and perhaps wider. I had been thinking of a similar idea but hadn't fleshed it out that far, so thanks for that

Cheers!

I saw one of those a number of years ago, thought some folks would go gaga over it, but it didn't seem to make as big an impact as I would have expected, given how many people complained about doing high gravity batches in a 10 gallon Rubbermaid (myself included)

I don't know about the price being more than triple a 10g cooler though. Ouchie. Maybe that's the hold-back...

Cheers!

Yep they are expensive (very proud of that cooler for sure). For that price I could just spring a stainless MLT or maybe a keg and turn my son loose on it. He would be more than happy to weld a few ports on it for me. Then I could step mash, using one of my LP burners.

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

I have a couple of questions/verifications if you don't mind. In order to properly manipulate said lid into a mash cap.

the mash cap, must have a flat bottom, to minimize the mash to O2.

The mash cap sides should be high enough to not allow swamping

Add LODO strike and sparge from the bottom of the MLT, with minimal splashing or exposure to O2

How do you handle lautering

or recirculation with a mash cap? Is it ok to drill a hole for a barb? I would think so as long as its not to heavy to swamp the lid.

I see you already got your answers for the drilling, return etc. I did cut the handle off off one of my lids and left it on the other, they both float but one is a bit lighter. Neither are drilled but it's a malleable grade of stainless and will drill just fine. A couple things about bending the lip.. use an adjustable wrench and just adjust it right down to the thickness of the lip. This will keep the lip from cupping. Then bend the lip a little then move over 1 wrench width and bend a little again. Do this little bending thing round and round the cap and just keep going a small amount at a time. What you are actually doing here, more than just bending the metal, is allowing/forcing it to shrink back together. This takes time and patience. The first cap I did it took a couple hours. The second one only 40 minutes because I knew how much bend at a time I could get away with. But for your maiden voyage.. slow and steady wins the race.

I see you already got your answers for the drilling, return etc. I did cut the handle off off one of my lids and left it on the other, they both float but one is a bit lighter. Neither are drilled but it's a malleable grade of stainless and will drill just fine. A couple things about bending the lip.. use an adjustable wrench and just adjust it right down to the thickness of the lip. This will keep the lip from cupping. Then bend the lip a little then move over 1 wrench width and bend a little again. Do this little bending thing round and round the cap and just keep going a small amount at a time. What you are actually doing here, more than just bending the metal, is allowing/forcing it to shrink back together. This takes time and patience. The first cap I did it took a couple hours. The second one only 40 minutes because I knew how much bend at a time I could get away with. But for your maiden voyage.. slow and steady wins the race.

Thanks for the pointers Blisch, I ordered the lid and yep, they also hit me for tax -:lol

I'll have to run a test it might float just fine without and bending. If not, I will bend the lip up.

If you don't have any hole in your mash cap, you must have two ports near the bottom of your mash tun to be able to recirculate? If you don't mind could you point me to a picture of your MLT?

I have a small amount of final leg work to do before executing my mash cap design...

Got a SS pizza pan that fits with 1/8" on each side. It's not super deep dish tho, so whatever I do needs to be light...

I'm thinking if I can drill a hole very cleanly, then I can just insert the silicone tube bare and it should seal...if that doesn't work a grommet may help.

Last resort-weldless bulkhead.

Plan is on the underside to do male barb to npt cap with holes drilled in sides...

I have all the parts...

Last step is pour water to see how much the pizza pan holds--then convert that to a weight...any hardware I use cannot weigh more than that (also including the pan).

We shall see!

Got a SS pizza pan that fits with 1/8" on each side. It's not super deep dish tho, so whatever I do needs to be light...

I'm thinking if I can drill a hole very cleanly, then I can just insert the silicone tube bare and it should seal...if that doesn't work a grommet may help.

Last resort-weldless bulkhead.

Plan is on the underside to do male barb to npt cap with holes drilled in sides...

I have all the parts...

Last step is pour water to see how much the pizza pan holds--then convert that to a weight...any hardware I use cannot weigh more than that (also including the pan).

We shall see!

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

[QUOTE="Jeff..., post: 8891247, member: 285537"

I'll have to run a test it might float just fine without and bending. If not, I will bend the lip up.

If you don't have any hole in your mash cap, you must have two ports near the bottom of your mash tun to be able to recirculate? If you don't mind could you point me to a picture of your MLT?

[/QUOTE]

You will have to debend the lip as the cap floats just at the line where the bend is.

Sure.. just go back in this thread to post #27, thats what the return under the mash cap looks like. It shoots up in the center and impinges on the bottom of the cap.

In post #36.. there is my debent mashcap in place.

And finally in post #37 is a diagram of the plumbing and pump for the circulation.

I'll have to run a test it might float just fine without and bending. If not, I will bend the lip up.

If you don't have any hole in your mash cap, you must have two ports near the bottom of your mash tun to be able to recirculate? If you don't mind could you point me to a picture of your MLT?

[/QUOTE]

You will have to debend the lip as the cap floats just at the line where the bend is.

Sure.. just go back in this thread to post #27, thats what the return under the mash cap looks like. It shoots up in the center and impinges on the bottom of the cap.

In post #36.. there is my debent mashcap in place.

And finally in post #37 is a diagram of the plumbing and pump for the circulation.

[QUOTE="Jeff..., post: 8891247, member: 285537"

I'll have to run a test it might float just fine without and bending. If not, I will bend the lip up.

If you don't have any hole in your mash cap, you must have two ports near the bottom of your mash tun to be able to recirculate? If you don't mind could you point me to a picture of your MLT?

You will have to debend the lip as the cap floats just at the line where the bend is.

Sure.. just go back in this thread to post #27, thats what the return under the mash cap looks like. It shoots up in the center and impinges on the bottom of the cap.

In post #36.. there is my debent mashcap in place.

And finally in post #37 is a diagram of the plumbing and pump for the circulation.

[/QUOTE]

I received the lid. I was hoping it would have a flat bottom but it is slightly concave. I may be able to make it flat once I cut the handle off of it. It fits well and I do believe it will float as is. After I make the mods, I'll test it and turn up the lip if needed. It is a nice thick gauge stainless lid though.

You will have to debend the lip as the cap floats just at the line where the bend is.

Sure.. just go back in this thread to post #27, thats what the return under the mash cap looks like. It shoots up in the center and impinges on the bottom of the cap.

In post #36.. there is my debent mashcap in place.

And finally in post #37 is a diagram of the plumbing and pump for the circulation.

I received the lid. I was hoping it would have a flat bottom but it is slightly concave. I may be able to make it flat once I cut the handle off of it. It fits well and I do believe it will float as is. After I make the mods, I'll test it and turn up the lip if needed. It is a nice thick gauge stainless lid though.

[/QUOTE]

Thanks for all the tips Bilsch everything is much appreciated

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

I received the lid. I was hoping it would have a flat bottom but it is slightly concave. I may be able to make it flat once I cut the handle off of it. It fits well and I do believe it will float as is. After I make the mods, I'll test it and turn up the lip if needed. It is a nice thick gauge stainless lid though.

Personally I'd leave the handle and the concave the way it is unless you are drilling a return port through it. I have two and the one with the handle works better.

This weekend I finally got around to trying to assemble a mash cap using this Kraftware 12” tray I bought on Amazon in 2018 - only $20 back then. Six drill bits later trying to make a pilot hole for my Greenlee punch, I gave up. Too bad because otherwise seemed perfect for my 10 gallon cooler MT. Next will try the pizza pan I bought before the aforementioned chunk of armour.

Get a couple of cobalt bits, use any oil you have on hand, use a ton of pressure and go slow - like a turn or two per second.

If the oil smokes, stop and let the bit cool.

If your eventual hole diameter is big enough to let you start at another point and still encircle the failure, do that as well, as you've likely hardened the original spot quite thoroughly...

Cheers!

If the oil smokes, stop and let the bit cool.

If your eventual hole diameter is big enough to let you start at another point and still encircle the failure, do that as well, as you've likely hardened the original spot quite thoroughly...

Cheers!

Thanks, but that’s exactly what I was doing. Unlike my kettle which cut like butter, this was pre-hardened. Snapped both cobalt and standard HSS bits - cobalt bits add up in a hurry. Problem was I was trying to start with 1/16” bits and those couldn’t hold up to the pressure being exerted with a handheld drill. Was able to make progress with a 1/8” bit and worked up to a stepper bit. Just about have a 3/8” hole for the punch stud. Hopefully won’t damage the punch. Will find out tonight.

Similar threads

- Replies

- 7

- Views

- 893

- Replies

- 24

- Views

- 2K

Latest posts

-

-

-

-

-

-

-

I just poured 42 bottles of HB Dunkelweizen down the drain

- Latest: Hoochin'Fool

-