I have completed my first two brew sessions, identical batches, and I came up low on my OG both times. I am trying to figure out if it's something in my process causing this low efficiency. Any input would be appreciated.

This is a 5 gallon all-grain kit I had the brew store split in half and crush for me so I could do two 2.5 gallon batches. I did this BIAB.

2.5 gallon batch size BIAB

5.5 lb. grain bill

Strike water 160

Mash at 155 for 60 minutes

Boil 90 minutes

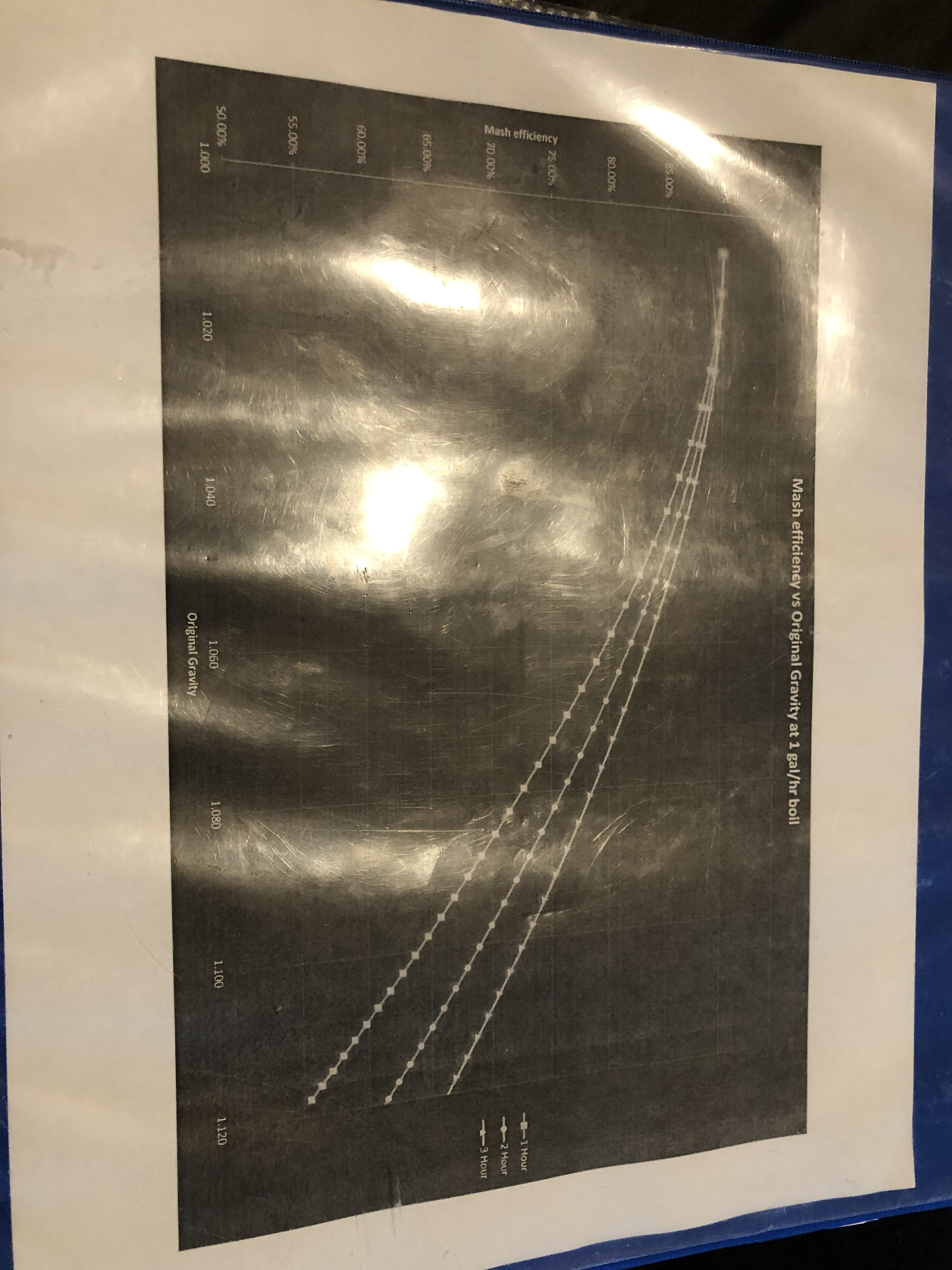

Target OG 1.054

The first batch I calculated the water amount with John Palmer's book for a 5 gallon batch and divided it in half, giving me 3.85 gallons starting. I was unable to control the temp well and had a very violent boil. I came up short 1 gallon and topped it up in the fermenter. My gravity reading was 1.040. Another forum member suggested maybe the water and wort didn't mix well throwing off my reading.

The second batch I used an online calculator for the water amount and started with 4.55 gallons. I modified my burner so I could control the boil this time. I also squeezed the bag to get as much wort as possible. I came out 1/2 gallon over. My OG was 1.046.

My boil off was obviously higher the first time. After I correct for that I think the water amount I used on the first batch was closer to the mark. Brewsmith says 4 gallons. Is it the water amount that is throwing me off on my gravity or another problem? Maybe the grain needs to be crushed differently? What am I missing?

Thanks everyone!

This is a 5 gallon all-grain kit I had the brew store split in half and crush for me so I could do two 2.5 gallon batches. I did this BIAB.

2.5 gallon batch size BIAB

5.5 lb. grain bill

Strike water 160

Mash at 155 for 60 minutes

Boil 90 minutes

Target OG 1.054

The first batch I calculated the water amount with John Palmer's book for a 5 gallon batch and divided it in half, giving me 3.85 gallons starting. I was unable to control the temp well and had a very violent boil. I came up short 1 gallon and topped it up in the fermenter. My gravity reading was 1.040. Another forum member suggested maybe the water and wort didn't mix well throwing off my reading.

The second batch I used an online calculator for the water amount and started with 4.55 gallons. I modified my burner so I could control the boil this time. I also squeezed the bag to get as much wort as possible. I came out 1/2 gallon over. My OG was 1.046.

My boil off was obviously higher the first time. After I correct for that I think the water amount I used on the first batch was closer to the mark. Brewsmith says 4 gallons. Is it the water amount that is throwing me off on my gravity or another problem? Maybe the grain needs to be crushed differently? What am I missing?

Thanks everyone!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)