- Joined

- Feb 16, 2012

- Messages

- 3,355

- Reaction score

- 4,220

- Location

- Either in the brewery or on the road

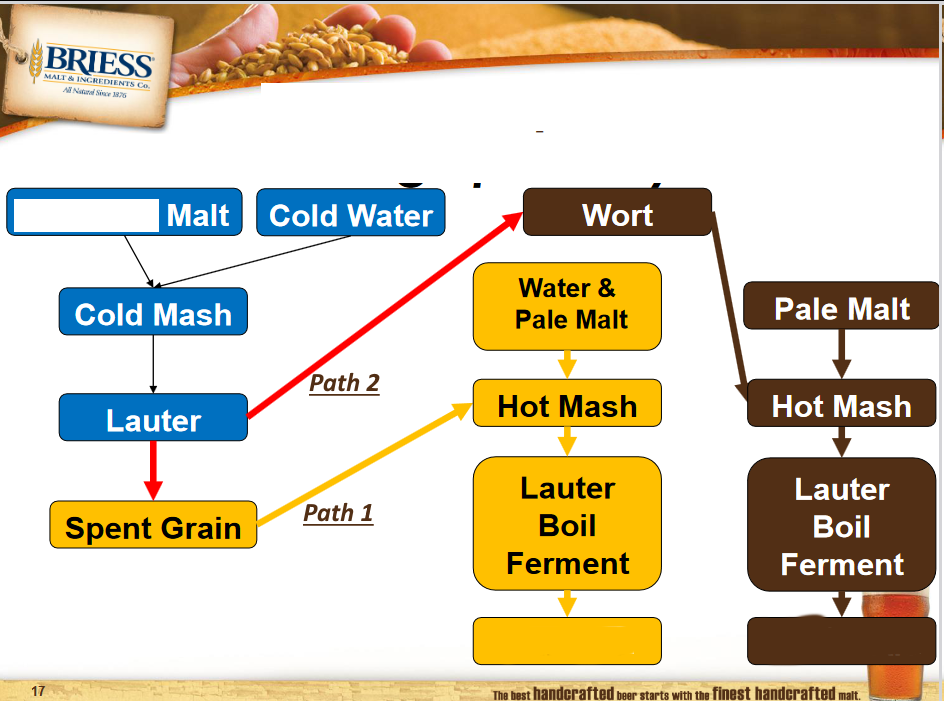

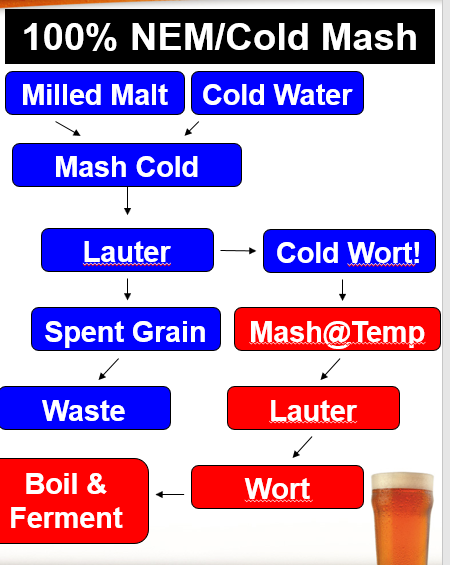

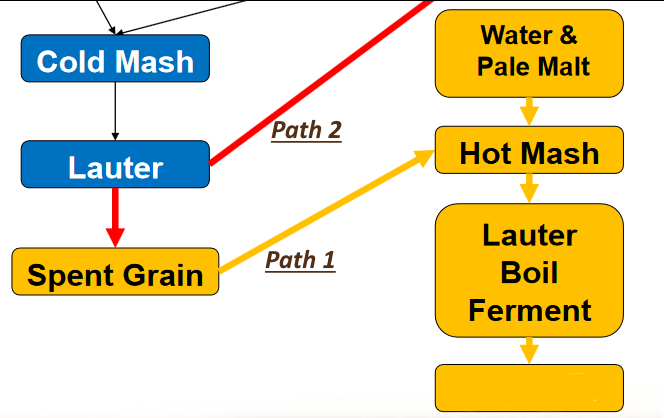

For several months I’ve been spending the idle hours pondering the potentials and pitfalls of brewing a Low-Enzymatic Mash beer. The process has been out there on the fringe of brewing for a couple of years with some interesting lab and brewery type research, including Briess, that has some good info on their website. For those not familiar with LEM, or if you glanced at it once and brushed it off with a quick, “Oh, that’s “nice,” dismissal, the process involves a hydrolyzing cold mash (more like steeping) at 40F for 4-12 hours in order to extract 90%+ of all the color, flavor, and ‘mouthfeel’ components while leaving behind 75% of the convertible starches.

The grains are removed leaving behind the wort with nearly all the color and flavor components intact, along with a trub-like settled layer of unconverted starches at the bottom. That means that a normal 1.050 OG grain bill from a regular congress mash will result in an actual OG of somewhere around 1.020 and a final ABV 0.5%-1.5% beer that has the taste, color and body of a normally mashed grist. The wort is siphoned off the trub into the boil vessel for a hot mash.

Enough enzymes are recovered in the process to convert the sugars left behind during a subsequent traditional 154F heating mash. After conversion is complete, the temperature is increased to boiling, and a standard brew process is conducted with hops additions, chilling, and knock-out for fermentation. The finished beer has most of the components of a normally produced beer, but with less than a quarter of the ethanol. The conundrum (and opportunity) is how best to recycle the ‘partially’ spent grains for a second party-gyle beer. It seems like adding flaked rice along with white wheat and mashing with the original grist in a second normal congress mash would have more than enough diastatic power to fully convert the mash, especially if the starch dregs from the cold mash were tossed into the mix. At least it should be sufficient to brew a small beer or table beer.

The literature I’ve come across gives a lot of empirical data about color, flavor components, dextrins and the like, but very little about enzymes that remain in the settled trub and spent grains. Has anyone tried this method, particularly the secondary batch? I’d like to hear any experiences or hints for success. Or failures that might convince me to not waste my time.

The grains are removed leaving behind the wort with nearly all the color and flavor components intact, along with a trub-like settled layer of unconverted starches at the bottom. That means that a normal 1.050 OG grain bill from a regular congress mash will result in an actual OG of somewhere around 1.020 and a final ABV 0.5%-1.5% beer that has the taste, color and body of a normally mashed grist. The wort is siphoned off the trub into the boil vessel for a hot mash.

Enough enzymes are recovered in the process to convert the sugars left behind during a subsequent traditional 154F heating mash. After conversion is complete, the temperature is increased to boiling, and a standard brew process is conducted with hops additions, chilling, and knock-out for fermentation. The finished beer has most of the components of a normally produced beer, but with less than a quarter of the ethanol. The conundrum (and opportunity) is how best to recycle the ‘partially’ spent grains for a second party-gyle beer. It seems like adding flaked rice along with white wheat and mashing with the original grist in a second normal congress mash would have more than enough diastatic power to fully convert the mash, especially if the starch dregs from the cold mash were tossed into the mix. At least it should be sufficient to brew a small beer or table beer.

The literature I’ve come across gives a lot of empirical data about color, flavor components, dextrins and the like, but very little about enzymes that remain in the settled trub and spent grains. Has anyone tried this method, particularly the secondary batch? I’d like to hear any experiences or hints for success. Or failures that might convince me to not waste my time.