Alright, so this weekend was "the time". Saturday, to be precise. Our wonderful, 36°C Saturday.

I started out the morning with some friends over to finish off some beers I had so I could use the bottles. Why? Well, because I needed bottles. Because the previous beer (Munton's IPA Bitter) was still in the fermenter, for a respectable while at this stage. Want to see how that one turned out (so far)? Check

here. Anyway, we finished off a few bottles and a mini keg during a "beer breakfast". You can have champagne during breakfast, so why not beer?

Anyway.

Now they're gone, and I get to work. I borrowed a big-ass urn from a forum member (

@Langchop) to see how this AG/BIAB thing will go. Great oke, so big props and a sincere thanks to him!

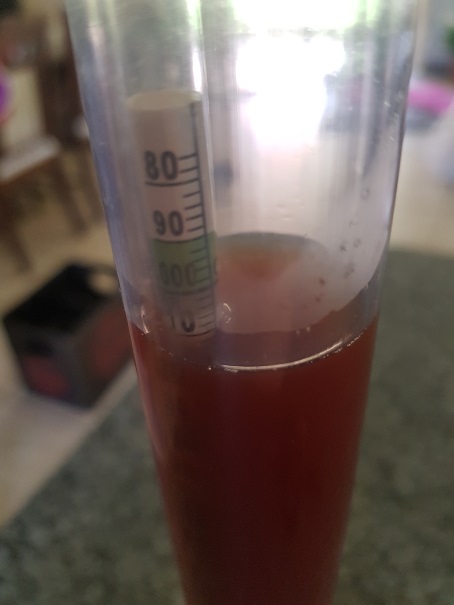

Back to brewing! I put a bunch of water in the urn. 15l, it looks like. Respectable amount. I'm aiming for a strike water temp of around 71°C so I turn the urn's thermostat to JUSt under 70°C. I leave it for about 45 minutes, look up to see it's on "keep warm", so it hit temperature. Take my probe thermometer, dump it in the water. 88°C. Aww yay.

Overshot the temp by far. So I take off the lid off the urn, turn it off and wait. For almost an hour. During this time I get started on bottling the beer currently occupying my fermenter. Sanitize the bottles, wash out the mini keg, etc. Halfway into bottling I check on the temps and they're at 69°C. Close. Turn up the thermostat a little bit, set the probe thermometer in the urn and set the alert alarm for when it hit 70°C, which it does in a matter of seconds. Turn the thermostat so that it's at the current temp and hold it there.

Next step - sink the brew bag. It's a lekker big bag so it goes over the entire rim with ease. It's deep, so it goes lekker deep into the water. Probe of the thermometer is still in the kettle, just above the element on the protective grid. I reckon it's a good spot to check for temps, since the wort above will be slightly cooler. So I set the thermometer to 72° so it'll warn me when temps go a tad high, I added the grains and stirred. Water temperature dipped to 69°C again, but I turned up the heat to get it to 70°C again. Set the timer for an hour, and continued on the bottling. I stirred twice during the time of the mash as well, just FYI, and the temps stuck at 70°C for the duration.

Right, so mash is done. I lift up the bag and the first thing I see is...holy crap it's heavy! 1kg of grains take up A LOT of water! Anyway, I lift up the bag and now I realize how frigging dark the wort is. I completely overshot the colour I was aiming for, but more on that later. So I squeeze the bag a bit, burn my hands like mad, and realize this ain't gonna work. I need to find something to place this bag in. Bag in hand I kinda hobble over to the cabinet where the pots are, and wort is dripping all over the kitchen floor. Seriously glad wife's not seeing this. Get a pot, dump the bag and now I'm taking a look at this situation.

Got a pot with a hella hot bag in it, and I don't know how to get the water out. I know about sparging, so I turn on the kettle. Halfway into pouring the hot water over the grains I realize I'm just making my problem worse - I'm going to burn even more. So I stop. Squeeze the bag as much as I could and pour that wort into the urn. I then sparge with cold water, because it needs to cool down. At that cooler temp I manage to get the grains pretty dry by squeezing the bag and add that wort to the urn.

Great. I'm at about 14l in the urn remaining, so not a lot of loss. Now for the boil. Probe thermometer is back into the urn and I turn up the heat. A lot. Set the probe to 98°C because we mos boil cooler than at the coast.

Yeah no.

Thing screams like mad a 98°C but no boiling. So I turn it to 100°C. Same story. The wort only starts to boil when the temperature hit 102°C.

No worries. I add my 60-minute hop addition. I'm not entirely sure what the weights were (I wrote it down at home, so I'll have to check), but I think it was 10g Admiral and 6g U1/108. I decided on this combo as the Admiral has good bittering qualities and the U1/108 apparently has good tropical flavours when it's boiled for a long time. So I boil them for a long time. Set a timer for 45 minutes and wait.

At 45 minutes I add my 15-minute hop addition. I add more U1/108 for flavour, and I think here I added 8g. Could be 6g, but I'm not sure. Anyway. It's boiling.

After 15 minutes I turn off the kettle, and then my issue hit. Now I need to cool this **** down. I read all kinds of bad things about wort that stays too hot for too long, so I'm worrying now. With the urn turned off I'm expecting the temperature to drop slowly, but it doesn't. Langchop took this double-wall urn and insulated the gap between the walls, meaning this thing keeps heat. It keep heat WELL.

Plan B. I kinda expected this, so during the previous week I've been running and ice machine to make some ice for me should I need it. Clean water, no worries.

Well I need it. I start adding ice. And more ice. And more ice. And more. Suddenly I'm out of ice. Thermometer still reads 64°C. So what now? OK, cold water from the fridge (also clean, don't worry). Doesn't do much. 63°C.

I'm out of ice and out of cold water, so I do the only thing I can do - let it sit and cool down on it's own, while I hope and pray there's no trouble with the wort. I start a fan and let it blow on the urn as well. No difference.

Now at this stage I need to point out that my plan was to pour cooled wort directly onto the yeast cake in my fermenter. Obviously this isn't going to work, so I go to work on the yeast cake. I swirl it up and pour it out into two clean glass bottles. I lid them and set them aside to separate. I need to harvest the yeast and get rid of as much of the previously fermented beer, no?

So I just rinse out the fermenter to get rid of the old krausen ring and decide to pitch the still warm wort into the fermenter. I do so. It's a mess, it splashes everywhere out of the tap of the urn. Eh. I'll clean up later. During this time I remember I have some lactose in the pantry and figure I'll just toss it in there as well. What's there to lose? I weigh it out - 140g - and add.

With the wort into the fermenter and see I'm 6l short to my aimed volume. Add clean, cold water. Temperature in low 50's now. Still waaaay to hot to pitch yeast. I place the fermenter in my cooler box and pack it with ice packs. Cold, wet towel draped over the top to aid cooling. It's not working lekker. After an hour the stick-on thermometer still glows on the 40°C mark. I'm out of ice, I'm out of ice packs and I got nothing left. I stick a bottle of frozen milk in there. Slooooowly the temperature starts to come down.

By now it's bedtime. It's 22:00 and the wort is still warm. The stick-on thermometer reads 32°C. The yeast has been washed and it's clean. I just have no other choice, it's bedtime and I can't let the wort sit like this. The fermenter has not been sanitized and something WILL happen. So I pitch the yeast. The entire cake. I had the yeast at room temp, at least, and the outside temperature of 36°C means the yeast is at least close to the wort temperature. Not ideal, but eh. Can't keep worrying over this. I sink the airlock, wet the towel again, add the last bit of ice that the ice machine has been making during this time on top of the towel so it can trickle cold water down the side of the fermenter and go to bed.

At around 2:30 I wake up. I get up to check on the wort, because I'm worried. Torch in hand I turn off the alarm, unlock the security gate and head to the kitchen. Whole house smells like chocolate wort. I'm happy, wife not so much. Anyway, get to the fermenter and check the temps. YES! It's coming down, the milk bottle is working, along with the ice. It's at 24° and coming down. Not too bad. Luckily the M42 yeast is a very clean yeast, so I can only hope it didn't stress too much.

Anyway, Sunday morning I took a look again and found the fermenter at 20°C. That's my target temp, so I'm happy. I keep adding ice and ice packs to keep it there, check through the lid and see some foaming on top. Only a little bit, but there's activity - YAY.

During the course of Sunday I leave it alone, and last night I took a look inside. There's a krausen ring. Not big, not thick, at all, but that's to be expected. There's a definite CO2 smell, but nothing else. No off smells yet, which is GREAT. Close it up and let it sit.

This morning I checked on it. The smell from the fermenter is great. There's CO2, but there's also sweet chocolate notes and some great hop aromas coming off. I took a tiny little taste test and, to be honest, I think it's OK. I expected a much more watery brew, but it actually had pretty good aroma and flavour. Body is a bit on the down-low, but that's to be expected. It has a sweet-ish caramel-chocolate taste, and it reminds me of a stout. Wasn't what I was aiming for, but it did give me some good ideas.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)