Thundercougarfalconbird

Well-Known Member

- Joined

- Dec 16, 2010

- Messages

- 760

- Reaction score

- 25

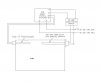

I'm slowly planning adding an element to my kettle to use as a HLT/BK

I want it to have some way to control the temperature for strike/sparge water, but also want to be able to crank it up for a boil. What kind of controller do I need?(I can't find a good guide for my needs. The electric Brewery is far to complex and a built in heat stick is too simple)

I want it to have some way to control the temperature for strike/sparge water, but also want to be able to crank it up for a boil. What kind of controller do I need?(I can't find a good guide for my needs. The electric Brewery is far to complex and a built in heat stick is too simple)

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)