I'm going to give this thread a bump. this does not deserve to be on second page, rather should be in the sticky section.

P-J, you're a hero. Your knowledge is absolutely priceless!

I was wondering if I can run some things by you, P-J, and others on here. I'm slowly putting together a kit to automate my BIAB brewing. My current setup is a 10 gallon pot that sits over two electric stove top elements. I can get 8 gal of wort boiling no problem, but I'm thinking of putting an electric element to control mash temp better and get to boil quicker.

here's what I have so far:

1x 5500w camco element which I'm planning to use with 120v. 1375w should be plenty to maintain mash temp and be safe for 15amp outlet (right?)

1x SYL-2352 PID

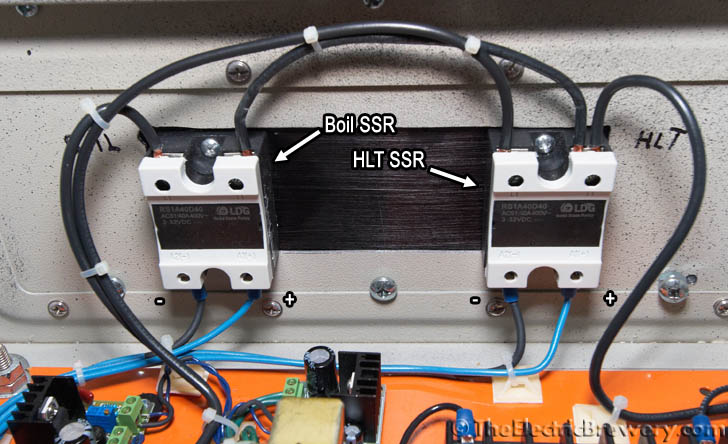

1x 40amp SSR

1x K type thermocouple

1x 12v high temp 108gal mini pump which I use to recalculate the wort during mash. (

http://www.amazon.com/dp/B007XZAJ3I/?tag=skimlinks_replacement-20)

The whole setup does not have to be anything fancy, no real need for on/off switches other then pump switch(12v), unless there are good (safety) reasons for it. I would like to have an e-stop button tho.

I'm looking for the best way to hook all of this up together.

Thanks in advance!