TNugent

Well-Known Member

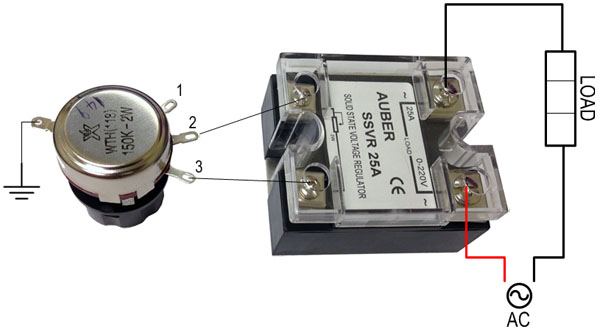

If needed, I can adjust the diagram to include an interlock or any other changes that you might need or want.

Just saying. I think this old man can wrap my head around your plan.

(LOL)

P-J

If you are bored stop by my three pronged outlet thread and look at my last entry to see if you could throw some input my way.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)