I like the idea of using a knob to control the boil vs. a PID's manual-mode much like HighGravity's EBC SV with Infinite Power Control.

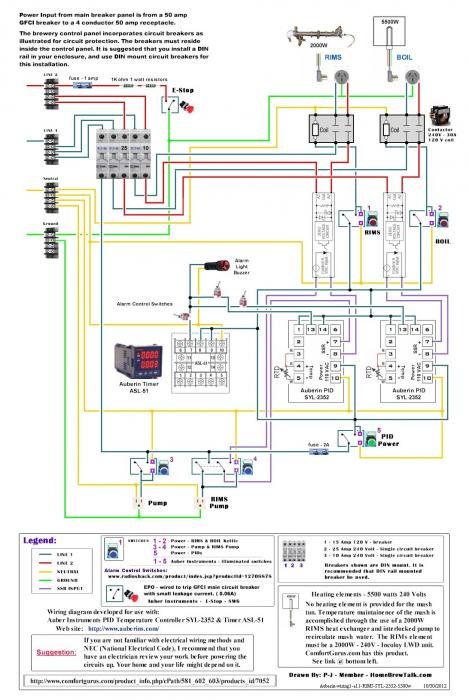

I'm looking for guidance on using a SSVR in P-J's "Single Element BIAB 30A PID" circuit?

I think I'd need to use a PID with Relay output (2342?) and I'd need to move the SSVR between the contactor and element.

Would this allow the PID to drive the contactor for temperature controlled mashing?

I believe I'd also need a 3-way switch that would allow the contactor to be energized by either the PID (for mashing), Manual (for boil), or Off.

The SSVR knob would be set to 100% for the mash and adjusted accordingly to control the boil.

Thanks in advance

I'm looking for guidance on using a SSVR in P-J's "Single Element BIAB 30A PID" circuit?

I think I'd need to use a PID with Relay output (2342?) and I'd need to move the SSVR between the contactor and element.

Would this allow the PID to drive the contactor for temperature controlled mashing?

I believe I'd also need a 3-way switch that would allow the contactor to be energized by either the PID (for mashing), Manual (for boil), or Off.

The SSVR knob would be set to 100% for the mash and adjusted accordingly to control the boil.

Thanks in advance

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)