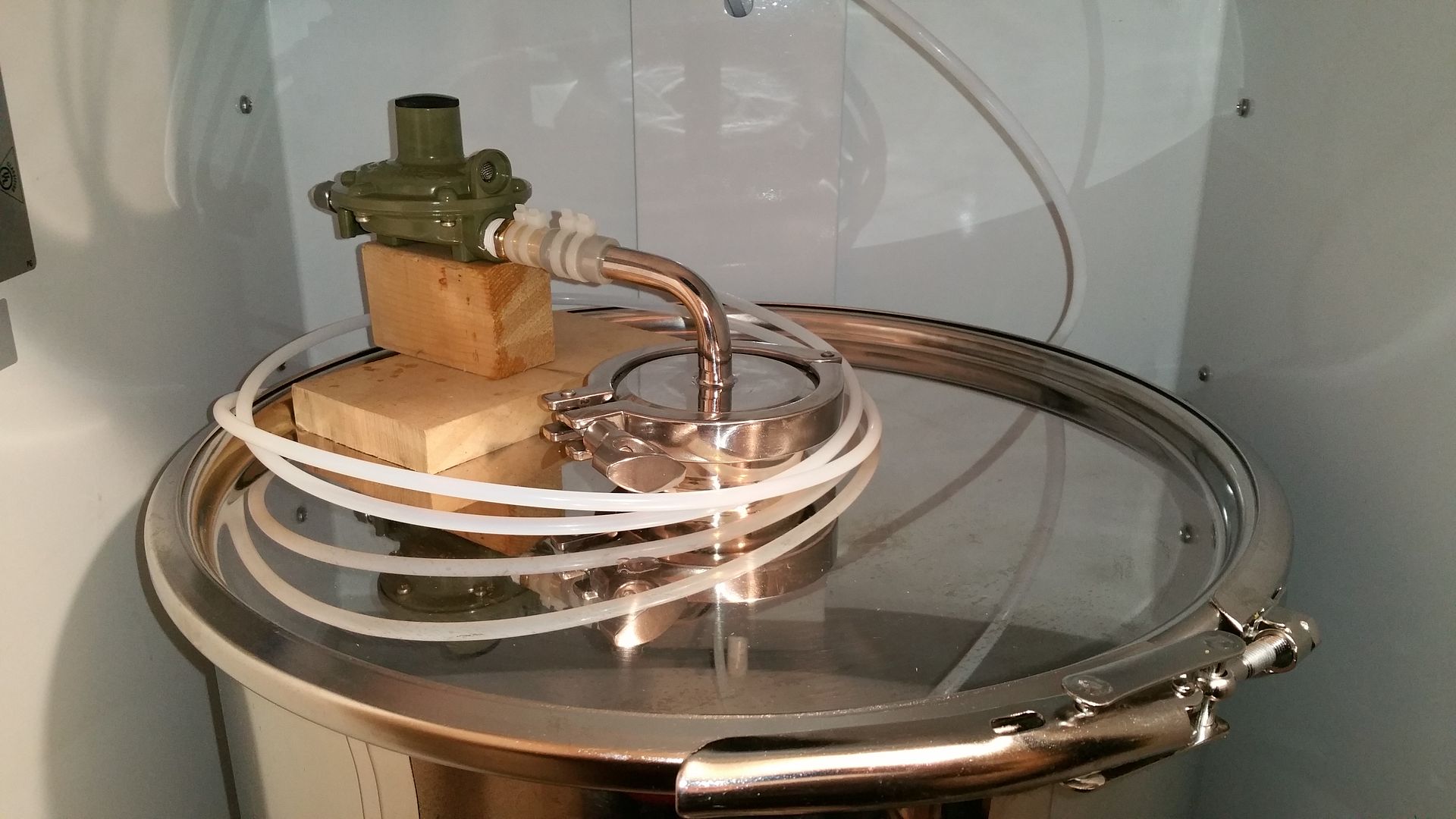

Super clean as always. What's the 1/4" valve on the ouput for? Sample port?

No, you will not be able to get a sample out of that unless the pump is not running. If it's running, it will actually suck air. That valve lets me insert a thermometer into the recirculating wort stream while it's recircing, without any disruption, to check the temp (not that I need to as the PID should be handling that task. It's just to double check that the mash is going as planned). It's a 1/4" ball valve with 1/2" male NPT thread welded to one end (so I can screw it into any fitting on my system) and a 1/4" compression fitting welded to the other end. I use silicone 0-rings in the compression fitting for easy thermometer insertion and removal. What's cool about it is that I don't need to dedicate a thermometer to the MT outlet because I can remove it whenever I want. It lets me take temperature measurements of the MT outlet and any other stuff during the brew day with my best thermometer.

What's going on with your system? I can't wait to see some progress pics. Your stuff is super clean!