My wife has given me the OK to look into getting another keg and ditching bottles altogether. My current process is to make a batch to keg, then wait a few weeks and make a batch to bottle. That way, there is always something in the home brew available (if they are good of course). I would have to keep the second keg at room temp probably in my closet that has not gotten above 73 degrees ambient since I have been paying attention. In the research that I have done (search of this site mostly) it seems that a full Corny keg with the head space purged of any O2 can be stored at room temp for up to six months? I don't think I will need it that long, but would that be a good guess? My beers have been of the hoppy variety, mostly IPA's and delving into the Pale Ale and even Blonde Ale arena. So, with that said, would I be safe to store a full Corny keg of say and IPA for a month or two at room temps? If not, I will keep the bottles as I have collected enough bottles to make 3 5 gallon batches. They do take up a bit of space, and honestly I don't mind. But heck, if she gives me to go ahead why not. My end goal is to have either a bigger fridge that will serve 3 or a keezer, so this is a small step towards that goal. Any input is greatly appreciated. And yes, I have used the search button so this is just more for confirmation of what I think I already know. RR

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Keg storage

- Thread starter redrocker652002

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I would add that to my priority list. You can buy old(er) and well working fridges (or freezers) rather cheap locally (family and friends, neighbors, CL, MP, etc.).My end goal is to have either a bigger fridge that will serve 3 or a keezer,

A common "top-freezer fridge" can hold 5-6 kegs in the bottom fridge section, if you build a plywood or plastic floor above the hump. You can mount faucets through the side (you can drill through the sides pretty much at will) or through the door. The (top) freezer section can be used for hops storage.

You can even store bottles and cans on a shelf above the kegs, and some in the space underneath the kegs.

That is the end game, but for now, storage of a bigger fridge is not possible. My garage doubles as my wife's craft room and my son's work shop, so for now a single kegerator tucked in the kitchen is what I have. Plus, adding lines, taps and all that is another cost that I cannot incur right now. So, my option is to keep bottling every other like I am doing now, or try and store a second keg that I can swap out when my other runs dry.I would add that to my priority list. You can buy old(er) and well working fridges (or freezers) rather cheap locally (family and friends, neighbors, CL, MP, etc.).

A common "top-freezer fridge" can hold 5-6 kegs in the bottom fridge section, if you build a plywood or plastic floor above the hump. You can mount faucets through the side (you can drill through the sides pretty much at will) or through the door. The (top) freezer section can be used for hops storage.

You can even store bottles and cans on a shelf above the kegs, and some in the space underneath the kegs.

This brings me to another question. If I am simply swapping kegs and the lines never really go dry, do I have to clean them out? I am guessing I will, so the dry keg will get cleaned and sanitized after use so I can pump some cleaner thru the lines and tap. Sound about right?

NSMikeD

Well-Known Member

I brew 2.5 gal batches and like to have one on tap and at least one on deck. These fit nicely in a min fridge. I modded a mini fridge to a kegerator that I inherited when my son returned from school and the second one is my fermentation/storage cabinet with a temp controller, which I got used for under $100.

When I change kegs I rinse well with warm/hot water and run some clean water thru the keg lines. I can use tap cleaner but haven't needed to yet. I store the empty kegs with a lid slightly on to keep dust and debris out and ensure they stay dry. I don't see a need to sanitize after a good cleaning before storing. When I am ready to keg I use star san. I remove the poppets and clean then every few batches.

The 2.5 gal batches uses less space, enables me to have a beer on tap and one on deck, and I get to try out different recipes more frequently.

When I change kegs I rinse well with warm/hot water and run some clean water thru the keg lines. I can use tap cleaner but haven't needed to yet. I store the empty kegs with a lid slightly on to keep dust and debris out and ensure they stay dry. I don't see a need to sanitize after a good cleaning before storing. When I am ready to keg I use star san. I remove the poppets and clean then every few batches.

The 2.5 gal batches uses less space, enables me to have a beer on tap and one on deck, and I get to try out different recipes more frequently.

Thanks for the reply. I am thinking the same thing about cleaning, but might modify my process a bit if I ever go this route.I brew 2.5 gal batches and like to have one on tap and at least one on deck. These fit nicely in a min fridge. I modded a mini fridge to a kegerator that I inherited when my son returned from school and the second one is my fermentation/storage cabinet with a temp controller, which I got used for under $100.

When I change kegs I rinse well with warm/hot water and run some clean water thru the keg lines. I can use tap cleaner but haven't needed to yet. I store the empty kegs with a lid slightly on to keep dust and debris out and ensure they stay dry. I don't see a need to sanitize after a good cleaning before storing. When I am ready to keg I use star san. I remove the poppets and clean then every few batches.

The 2.5 gal batches uses less space, enables me to have a beer on tap and one on deck, and I get to try out different recipes more frequently.

Unfortunately, I already have a 5 gallon keg, and like I said, room is a problem. I cannot get another fridge or even mini fridge in whatever space I may have, so I am thinking of just having another keg on deck as you say. LOL. As I said before, my end game is to get a used fridge with a freezer on tope and that would set me up to have 3 or 4 taps running with different styles. And use the freezer for glasses, and supplies. That will not happen until we move, the kids move out or I can get enough space in my current situation.

NSMikeD

Well-Known Member

Thanks for the reply. I am thinking the same thing about cleaning, but might modify my process a bit if I ever go this route.

Unfortunately, I already have a 5 gallon keg, and like I said, room is a problem. I cannot get another fridge or even mini fridge in whatever space I may have, so I am thinking of just having another keg on deck as you say. LOL. As I said before, my end game is to get a used fridge with a freezer on tope and that would set me up to have 3 or 4 taps running with different styles. And use the freezer for glasses, and supplies. That will not happen until we move, the kids move out or I can get enough space in my current situation.

I assume you don't have the ability to control fermentation temps other than slight variation from room temperature. So likely you'll be fermenting, aging and storing in the same environment. In your plans give thought to temp control on your fermentation. Essential with lagers and a game changer on ales. My mini fridge doubles a fermentation chamber, cold crashing and aging. Once in the keg I keep a cartridge CO2 on it since I cant fit a 5lb bottle inside it.

With your current set up, you'll need to plan a day or two of no beer for cold crashing to clear up the beer.

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

Think of your new (extra) keg as a large single “bottle”. Batch prime like you’re going to bottle and fill the keg. Set it aside and wait just like you would for the bottles. It will be carbonated and ready to serve when you’re ready for it.

Thank you for the response. I am still playing around with my temp control. I have it pretty close I think with my closet, a mini heater and if needed a fan with some ice near it to blow cold air. I am going to clean and sanitize my Inkbird and use the temp probe in the wort and see how that works. I want to try and see more how to store a full keg so I am ready when it is ready. We will see. Right now, it is more just having bottles and a keg to keep me going. RRI assume you don't have the ability to control fermentation temps other than slight variation from room temperature. So likely you'll be fermenting, aging and storing in the same environment. In your plans give thought to temp control on your fermentation. Essential with lagers and a game changer on ales. My mini fridge doubles a fermentation chamber, cold crashing and aging. Once in the keg I keep a cartridge CO2 on it since I cant fit a 5lb bottle inside it.

With your current set up, you'll need to plan a day or two of no beer for cold crashing to clear up the beer.

DuncB

Well-Known Member

I would be cautious about drilling through the side of a fridge at will. Newer fridges have cooling lines in the sides of them.

Older fridges with a metal grille condenser on the back I'd say you can drill through at will.

Older fridges with a metal grille condenser on the back I'd say you can drill through at will.

To reiterate what others are saying, yes, you can treat the keg like a big bottle and store it for a time at room temperature. If you’re doing this with very hoppy beers, here’s a reason to be more particular when it comes to getting O2 out — keeping a keg cold lets you be sloppier about oxygen ingress, but for long storage at room temperature you need to bring your A game. Keg conditioning will help with this, but you also want a closed transfer, and maybe some sulfites.

I’m usually lackadaisical about cleaning tap lines when swapping kegs. I feel guilty about it, though. If you don’t mind being a bad person, you can clean much less often. It hasn’t bitten me yet, and I go through a great many kegs.This brings me to another question. If I am simply swapping kegs and the lines never really go dry, do I have to clean them out? I am guessing I will, so the dry keg will get cleaned and sanitized after use so I can pump some cleaner thru the lines and tap. Sound about right?

Brushwood Brewing

Cast your bread upon the waters

- Joined

- May 5, 2022

- Messages

- 208

- Reaction score

- 344

To reiterate what others are saying, yes, you can treat the keg like a big bottle and store it for a time at room temperature.

Assuming beer degrades in a keg similarly to in bottles at room temperature, I've found my bottled IPA was noticably worse off after 6 months at room temperature storage. Based on my limited experience, I'd say aim for <4 months.

If it gets cold where you live you can use the weather to your advantage and store the extra keg in the garage or shed or whatever you have during the colder months. Obviously don’t do that in the summer months.

So, if I am reading correctly, if I add the priming sugar mixture to the keg, at the rate needed for a 5 gallon batch, seal the keg and open the PRV, let it sit in my closet at say 68 to 70 degrees that will be ok to keep the keg for a few weeks until I finish the other one? Or do I keep the PRV closed so that the sugar will start the carbonating process and add the CO2 when I put it in the kegerator. Just trying to dumb it down to my level. LOL.

Keep the PRV closed. otherwise you are letting in O2. The priming sugar will carb the beer while you are waiting to "tap" the keg.So, if I am reading correctly, if I add the priming sugar mixture to the keg, at the rate needed for a 5 gallon batch, seal the keg and open the PRV, let it sit in my closet at say 68 to 70 degrees that will be ok to keep the keg for a few weeks until I finish the other one? Or do I keep the PRV closed so that the sugar will start the carbonating process and add the CO2 when I put it in the kegerator. Just trying to dumb it down to my level. LOL.

I prime kegs with corn sugar and set them in the kitchen for 2-3 weeks. It's a little cooler there on the hardwood floor then the rest of the house. If there is no room in my kegerator I move them to the basement or in the winter in an unheated garage until there is an opening.

I see you are in California so probably no basement there. I advise moving to a cool place after carbing is complete until you can refrigerate them. This is especially true for hoppy styles. And don't forget to purge the keg of oxygen after filling with your desired method and check into

closed transfer to keep out even more o2.

I see you are in California so probably no basement there. I advise moving to a cool place after carbing is complete until you can refrigerate them. This is especially true for hoppy styles. And don't forget to purge the keg of oxygen after filling with your desired method and check into

closed transfer to keep out even more o2.

Thanks fo all who replied. My method of transferring from my fermenter to the keg is to hook a line from the bucket to the out port of my keg. I purge the keg of O2 by filling up with CO2 a few times and opening the PRV. I then keep the PRV open as I gravity feed from the bucket into the keg using a ball lock fitting and line from the spigot to the out of the keg. I think this is a variation of a closed transfer, correct?I prime kegs with corn sugar and set them in the kitchen for 2-3 weeks. It's a little cooler there on the hardwood floor then the rest of the house. If there is no room in my kegerator I move them to the basement or in the winter in an unheated garage until there is an opening.

I see you are in California so probably no basement there. I advise moving to a cool place after carbing is complete until you can refrigerate them. This is especially true for hoppy styles. And don't forget to purge the keg of oxygen after filling with your desired method and check into

closed transfer to keep out even more o2.

That will work but is not ideal. When I don't use co2 from fermentation to purge I fill the keg with sanitizer, iodine type, shake it a bit and tilt it with the gas post on top. Then I hook up a gas QD with a short line and squirt some sanitizer in to fill up all the air space. Disconnect the gas QD and then push all the sanitizer out with botted co2 into buckets. These leaves a sanitized and purged keg to fill.Thanks fo all who replied. My method of transferring from my fermenter to the keg is to hook a line from the bucket to the out port of my keg. I purge the keg of O2 by filling up with CO2 a few times and opening the PRV. I then keep the PRV open as I gravity feed from the bucket into the keg using a ball lock fitting and line from the spigot to the out of the keg. I think this is a variation of a closed transfer, correct?

When filling I hook up a gas QD from the keg with a line back on top of the FV. This is a closed loop and the co2 from the keg goes back into the FV. If you don't want to use the gas line leave the PRV closed until the flow slows a lot or stops and then open the PRV to get it going again then close again and repeat. The more you make an effort to reduce oxygen the better and longer it will stay fresh.

Hope this isn't too hard or completed, I had pizza with a few beers tonight.

cheers

I should mention I leave a little pressure in the keg before filling and invert it over the sink with a gas QD on a trimmed down gas tube. This gets remaining sanitizer that's left in the bottom of below the pickup tube out, it blows out into the sink.

Like I said I've been sampling a 7.7% Saison tonight with my pizza so I might be a little long winded.

Like I said I've been sampling a 7.7% Saison tonight with my pizza so I might be a little long winded.

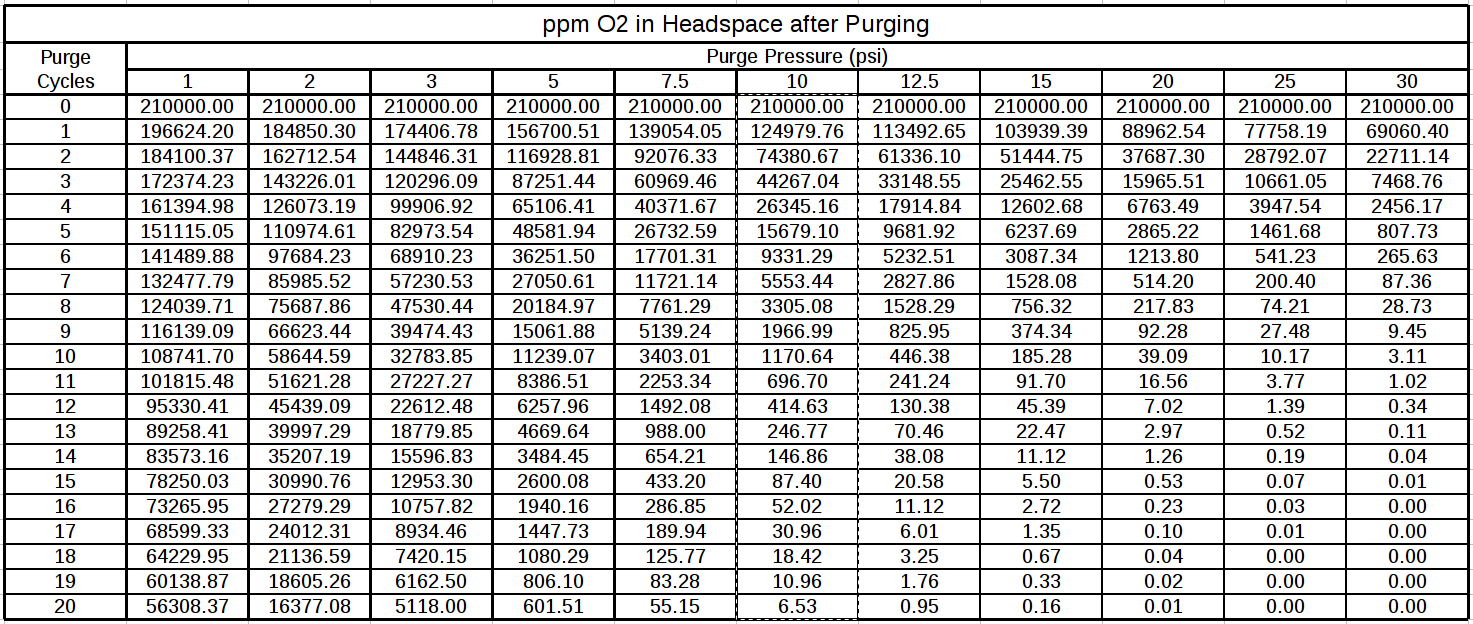

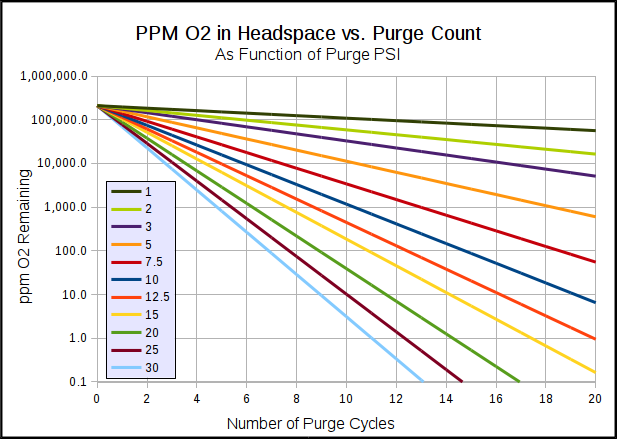

That's a very inefficient way to purge a keg, and not very effective unless you do a LOT of purges. If you pressurize at 15 psi and then vent, you only get about 1/2 of the O2 out. If you pressurize at 30 psi, then you get about 2/3 of the O2 out. Each succeeding pressurize/purge cycle gets the same fraction of the REMAINING O2 out. To get down to the single digit ppm or even less, you need many, many purges - see the table and chart below.Thanks fo all who replied. My method of transferring from my fermenter to the keg is to hook a line from the bucket to the out port of my keg. I purge the keg of O2 by filling up with CO2 a few times and opening the PRV. I then keep the PRV open as I gravity feed from the bucket into the keg using a ball lock fitting and line from the spigot to the out of the keg. I think this is a variation of a closed transfer, correct?

A more efficient way to purge is to fill the keg with sanitizer, and then push the sanitizer out with CO2 (save it in a bucket.) Even if you fill completely full, there is about 3 fl oz of air left in the lid due to the design of the PRV. For this reason, some people cut the gas "dip" tube, so that it doesn't extend below the bottom of the gas post fitting, and then tilt the keg when filling, such that the gas post is the highest point, so that no air is left in the headspace. You can also tilt the keg when emptying to get the last bit of sanitizer out.

The best way to purge a keg is to run all of the fermentation CO2 thru the keg. This is amazingly effective - single digit ppb (yes parts per BILLION) residual O2. You do need a fermenter that is air tight enough to hold a couple of psi pressure for this to work correctly.

Brew on

I honestly thought I was doing something good. You guys have me very confused now. I am not sure now what to do. I guess maybe I should just bottle? I see Youtube vids with the folks from Clawhammer and they just run a line thru the opening and just fill the keg that way. I don't really know what to do now. Damn, and here I thought I had it going pretty well. Oh well, guess not. So, run the sanitizer thru and leave the PRV alone? Then it will keep the CO2 in and keep the O2 out? I was going to keg tomorrow, now I have no idea what the heck I am going to do. RR

I suggest keeping it simple by filling the keg with sanitizer then tilting it with gas post facing up. Then try to fill the air space that is left with sanitizer. There is air left under the lid when you seal the keg like doug293cz stated. If you shake the full keg and hear sloshing, it still has air in it. If you shake it and don't hear sloshing the air was displaced. Then fill the keg from FV to out post on keg and leave the PRV closed. The flow will slow or stop at some point then open the PRV to start flowing again. Close the PRV and repeat the process. If that's too much to understand just leave the PRV open during and closing as soon as transfer is complete.

Just filling the keg with the lid off is going to expose the beer to oxygen the whole-time during transfer. You could do it this way to start out but drink it soon because it will start becoming stale soon after. Then study the methods I and doug293cz suggested. Keep the faith, methods get easier with time and practice. good luck

Just filling the keg with the lid off is going to expose the beer to oxygen the whole-time during transfer. You could do it this way to start out but drink it soon because it will start becoming stale soon after. Then study the methods I and doug293cz suggested. Keep the faith, methods get easier with time and practice. good luck

Thank you for the info. So, just to recap, fill the keg with sanitizer and tilt it so the gas line is facing up and "top it off" as best I can. If it sloshes, open the lid and keep pouring until I can get as much liquid in it as possible. Then, empty the keg by putting the gas to it and pumping it thru the tap with the CO2 hooked up and running it as dry as I can. There might still be a small amount of sanitizer in there, but I guess that is ok? After I do that, don't touch anything, put the line with a ball valve from the FV to the out post on the keg, open the line and let gravity do it's thing. If the flow stops, open the PRV until flow starts and close again. Repeat as needed until the 5 gallons of beer is in the keg. Does this sound right?I suggest keeping it simple by filling the keg with sanitizer then tilting it with gas post facing up. Then try to fill the air space that is left with sanitizer. There is air left under the lid when you seal the keg like doug293cz stated. If you shake the full keg and hear sloshing, it still has air in it. If you shake it and don't hear sloshing the air was displaced. Then fill the keg from FV to out post on keg and leave the PRV closed. The flow will slow or stop at some point then open the PRV to start flowing again. Close the PRV and repeat the process. If that's too much to understand just leave the PRV open during and closing as soon as transfer is complete.

Just filling the keg with the lid off is going to expose the beer to oxygen the whole-time during transfer. You could do it this way to start out but drink it soon because it will start becoming stale soon after. Then study the methods I and doug293cz suggested. Keep the faith, methods get easier with time and practice. good luck

My one question is, I have already sanitized the keg so can I just fill with water? I just realized mt CO2 tank is low, so I might have to go get another anyway, so this might be an afternoon trial, so I have time.

I am sorry for being so stupid about ths, but I want to try and get the best results I can, so if learning this method helps I am all for it.

Thanks again.

You could take a chance and fill it with water but if it was me, I'd refill with sanitizer. It is cheap compared to a batch of beer. When the keg is filled and tilted put on a gas QD with a short piece of hose. I use a syringe used with measuring acid to squirt more sanitizer into the short hose and fill the rest of air left under the lid. Remove the QD and shake to listen for sloshing, if heard add more sanitizer if not it's good.

After pushing out the san turn the keg upside down and move it around with gas QD on to get the last bit of san out over the sink or somewhere you won't get in trouble with the Mrs. Remove QD and you're ready to transfer.

I got tired of spelling out sanitizer each time! lol

good luck.

After pushing out the san turn the keg upside down and move it around with gas QD on to get the last bit of san out over the sink or somewhere you won't get in trouble with the Mrs. Remove QD and you're ready to transfer.

I got tired of spelling out sanitizer each time! lol

good luck.

If you open the keg to air, oxygen is going to get in. Better to leave a little bit of "San" in there -- it won't hurt anything. (A little bit won't. Too much and you have to start thinking about the oxygen dissolved in the San.)After pushing out the san turn the keg upside down and move it around with gas QD on to get the last bit of san out over the sink or somewhere you won't get in trouble with the Mrs.

I use iodine type for that reason. When I turn it to empty the last bit, I have left a little pressure in the keg, and it sprays out. I pop off the gas QD quickly after the sanitizer exits and still pressure left. You're right a little star san left won't hurt but I don't like leaving a little iodine sanitizer like I use.If you open the keg to air, oxygen is going to get in. Better to leave a little bit of "San" in there -- it won't hurt anything. (A little bit won't. Too much and you have to start thinking about the oxygen dissolved in the San.)

I didn't want to get too complicated for the guys first transfer.

Last edited:

OK, so after a decent nights sleep and a reread of the thread I think I got it now. I will try what you all say to do. Basically, I fill to the top with diluted sanitizer, run a small hose with a QD on the gas side. fill to the top, hook up the CO2 and run all the sanitizer out. Once empty, keep the pressure and put the small hose QD back on the gas side and turn the keg upside down and shake it to get as much sanitizer out as possible. Disconnect the small QD line, hook up my fermenting bucket to the Out line and transfer with the PRV closed. If the flow stops, and it will, open the PRV until the flows starts and close it up again. Keep doing this until I am done, then in the kegerator it goes to cold crash and carb up for my enjoyment. Am I close?

Looks good, if you use star san a little left in the keg won't hurt much like AlexKay said. So, if that's too much to start you could skip the extra sanitizer left as he says. I use the iodine type to reduce oxygen to start with, so I always invert the keg to get the last part out.

You might have to crack the stopper on top of the fermenter a little to make a vent to get it going too. Later you could add on a closed loop with a gas line from keg to stopper on the FV.

I do this and leave a little pressure in the keg to purge the lines with co2 before transfer and hooking them up. Start with what you can, and you can always add more complicated procedures next time.

You might have to crack the stopper on top of the fermenter a little to make a vent to get it going too. Later you could add on a closed loop with a gas line from keg to stopper on the FV.

I do this and leave a little pressure in the keg to purge the lines with co2 before transfer and hooking them up. Start with what you can, and you can always add more complicated procedures next time.

"There is more than one way to skin a cat" totally describes homebrewing. For me, the why of the process is the most important to understand. In this case, you want as little oxygen in the keg as possible. It's good to stretch yourself in a never-ending quest to improve your process but it can really be a bottomless rabbit hole. If you start feeling overwhelmed, just dial it back.

Several have recommended priming the keg like a bottle, which is my preferred method. I still try to minimize oxygen in the keg, but with this method the yeast will scrub the rest of the oxygen remaining. I usually use 125 grams of sugar to prime, which will get me in the ballpark, then fine-tune the carbonation after I tap it.

Several have recommended priming the keg like a bottle, which is my preferred method. I still try to minimize oxygen in the keg, but with this method the yeast will scrub the rest of the oxygen remaining. I usually use 125 grams of sugar to prime, which will get me in the ballpark, then fine-tune the carbonation after I tap it.

If it’s working for you great; don’t mess with it. I have read, (and been unable to relocate) that you can/(should?) reduce the priming sugar when carbing in a keg. This supposedly related to the reduced headspace in one keg as opposed to the +\- 50 bottles. The source I read suggested 2.5 oz by weight as sufficient, (71 grams). I don’t think it’s a big deal, but if you run into over-pressured kegs, or over-carbed beer, you might want to consider backing off a mite."There is more than one way to skin a cat" totally describes homebrewing. For me, the why of the process is the most important to understand. In this case, you want as little oxygen in the keg as possible. It's good to stretch yourself in a never-ending quest to improve your process but it can really be a bottomless rabbit hole. If you start feeling overwhelmed, just dial it back.

Several have recommended priming the keg like a bottle, which is my preferred method. I still try to minimize oxygen in the keg, but with this method the yeast will scrub the rest of the oxygen remaining. I usually use 125 grams of sugar to prime, which will get me in the ballpark, then fine-tune the carbonation after I tap it.

I have a keg I am trying at 2.5 oz. now. I put the sugar in a sanitized keg, purged with fermenter gas, and closed transferred the beer. I am setting it aside at 70° for 3 weeks to carbonate, then to the utility room outside for cool storage. If the temperature remains cool, I won’t even put it in the keezer. I have a stout on tap in that room now. Stouts are good at a little warmer temperature anyway.

This is total nonsense, but it is widely promoted and believed. There is very little difference in the keg headspace volume, and the combined headspace volume of ~50 bottles (I have measured. A keg and a bottle both have about 6% headspace) And, headspace volume doesn't have that much effect on carbonation anyway. I have not found anyone who can give a scientific explanation of why there would be a difference (and I don't think there is one, based on what I know about physical chemistry.)If it’s working for you great; don’t mess with it. I have read, (and been unable to relocate) that you can/(should?) reduce the priming sugar when carbing in a keg. This supposedly related to the reduced headspace in one keg as opposed to the +\- 50 bottles. The source I read suggested 2.5 oz by weight as sufficient, (71 grams). I don’t think it’s a big deal, but if you run into over-pressured kegs, or over-carbed beer, you might want to consider backing off a mite.

I have a keg I am trying at 2.5 oz. now. I put the sugar in a sanitized keg, purged with fermenter gas, and closed transferred the beer. I am setting it aside at 70° for 3 weeks to carbonate, then to the utility room outside for cool storage. If the temperature remains cool, I won’t even put it in the keezer. I have a stout on tap in that room now. Stouts are good at a little warmer temperature anyway.

Brew on

This is total nonsense, but it is widely promoted and believed. There is very little difference in the keg headspace volume, and the combined headspace volume of ~50 bottles (I have measured. A keg and a bottle both have about 6% headspace) And, headspace volume doesn't have that much effect on carbonation anyway. I have not found anyone who can give a scientific explanation of why there would be a difference (and I don't think there is one, based on what I know about physical chemistry.)

Brew on

Attachments

Update, I think I got it right. I had an extra QD and some hose, so I thought, hell, I can do this. I filled up the keg with starsan and water. I am lucky, my torpedo keg has a bit of a dome on it where the lid goes so it was easy to get it filled up. I ran it thru the tap and emptied it out. I never released the keg pressure, and added a line fine from the spigot to the out of the keg. I then added another QD from the in of the keg to the bung on the lid of the bucket. It was a tight fit, but that is what I was looking for to seal it. I then pumped a bit of CO2 from my tank, watched the lid bulge a bit, then put the QD on and opened the spigot on the bucket. I knew it was pressure filling because the hose I was using was very long and just gravity would not have pushed it into the keg. I am pretty stoked as it seemed to work well, and not much of the sediment got pushed into the keg. I then hooked up my line in the kegerator, put the CO2 to it and into the kegerator it went. The only other thing I am not sure of is if it was right to add the CO2 while the fridge gets down to temp, in a sense I guess I am cold crashing, but I can disconnect it if I need to. It is sitting at 15 psi and hopefully will take about 3 to 4 days to get up to carb level. If not, no worries, I can wait this time. I am looking forward to it as it smelled really good when I opened the bucket to clean everything.

Anyway, wanted to say thanks to all who had input and put up with my stupid questions. I am guessing if I decide to store a full keg for a few weeks, this is the process I use minus it going into the kegerator Again, thanks to all who had input and helped me get thru it. Rock on!!!!

Anyway, wanted to say thanks to all who had input and put up with my stupid questions. I am guessing if I decide to store a full keg for a few weeks, this is the process I use minus it going into the kegerator Again, thanks to all who had input and helped me get thru it. Rock on!!!!

I add Finished beer to a corny keg. Then I add priming sugar and hit it with CO2 to seal the keg, attach a spunding valve and let it sit in basement brewery. I have let some ”keg condition“ for weeks with no bad effects. When I eventually tap the keg it is carbonated to whatever level you select with your spunding valve. The in keg fermentation also eliminates or replaces any oxygen that may be present. A spunding valve is your friend and also saves CO2.So, if I am reading correctly, if I add the priming sugar mixture to the keg, at the rate needed for a 5 gallon batch, seal the keg and open the PRV, let it sit in my closet at say 68 to 70 degrees that will be ok to keep the keg for a few weeks until I finish the other one? Or do I keep the PRV closed so that the sugar will start the carbonating process and add the CO2 when I put it in the kegerator. Just trying to dumb it down to my level. LOL.

Thank you for that. I was not sure what a spunding valve was, but now I know. So, if I have read all of your posts correctly, I can sanitize, add priming sugar based on 5 gallons of beer, seal the keg with some CO2 and then add the Spunding Valve to the keg and that is enough to actually keep in my closet at temps between 65 to 70 for a few weeks?I add Finished beer to a corny keg. Then I add priming sugar and hit it with CO2 to seal the keg, attach a spunding valve and let it sit in basement brewery. I have let some ”keg condition“ for weeks with no bad effects. When I eventually tap the keg it is carbonated to whatever level you select with your spunding valve. The in keg fermentation also eliminates or replaces any oxygen that may be present. A spunding valve is your friend and also saves CO2.

Or, I can sanitize the keg, do the closed transfer that I did above, put some pressure to the keg and again store at 65 to 70 for a few weeks? This is all great info, and I want to do some research of fermenting in a keg as well, so maybe I can just get rid of my buckets altogether and go from kettle to keg and then to serving in one vessel. Thanks to all who replied, this was great info.

Just pressurizing doesn't work unless your keg is only 2/3-3/4 full of beer and you add all the needed CO2 for full carbonation, up front. That will result in a significant pressure (e.g., 60 psi when 3/4 full) to force carbonate that way.do the closed transfer that I did above, put some pressure to the keg and again store at 65 to 70 for a few weeks?

Alternatively, or if the keg is fuller, you can keep adding CO2 to the headspace over 1-2 weeks until you hit your intended volume of dissolved CO2.

When adding priming sugar the CO2 gets absorbed as it's slowly being generated, similar to in a capped or corked bottle.

Whichever way, it will take a few days to a week in cold storage for pressure and carbonation to stabilize.

The reason is that cold beer can absorb (dissolve) much more CO2 than warm/room, or even cellar temp beer.

Similar threads

- Replies

- 23

- Views

- 1K

Latest posts

-

-

-

-

-

-

-

-

For Sale SS Brewtech - 7 Gallon Unitank 1.0

- Latest: IslandLizard

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)