- Joined

- Dec 19, 2013

- Messages

- 316

- Reaction score

- 390

Oh good point. I’ll do that now.Perhaps add it into this thread.

https://www.homebrewtalk.com/threads/homebrew-talk-3d-print-thread.596124/page-6#post-10272580

Oh good point. I’ll do that now.Perhaps add it into this thread.

https://www.homebrewtalk.com/threads/homebrew-talk-3d-print-thread.596124/page-6#post-10272580

A ball lock keg has a total volume of about 5.3 gal or 678 fl oz. Due to the lid design, there is a volume of 3 fl oz that cannot be filled with liquid (for an unmodified keg.) When you then blow the liquid out of the keg with CO2, that 3 fl oz of air is dispersed throughout the entire keg volume. Thus the "starting" O2 concentration is:

210,000 ppm * 3 / 678 = 930 ppmSo, doing a liquid purge is almost equivalent to doing 5 purge cycles at 30 psi. Thus you still need 8 more 30 psi purge cycles to get down to the ~100 ppb O2 range.

Brew on

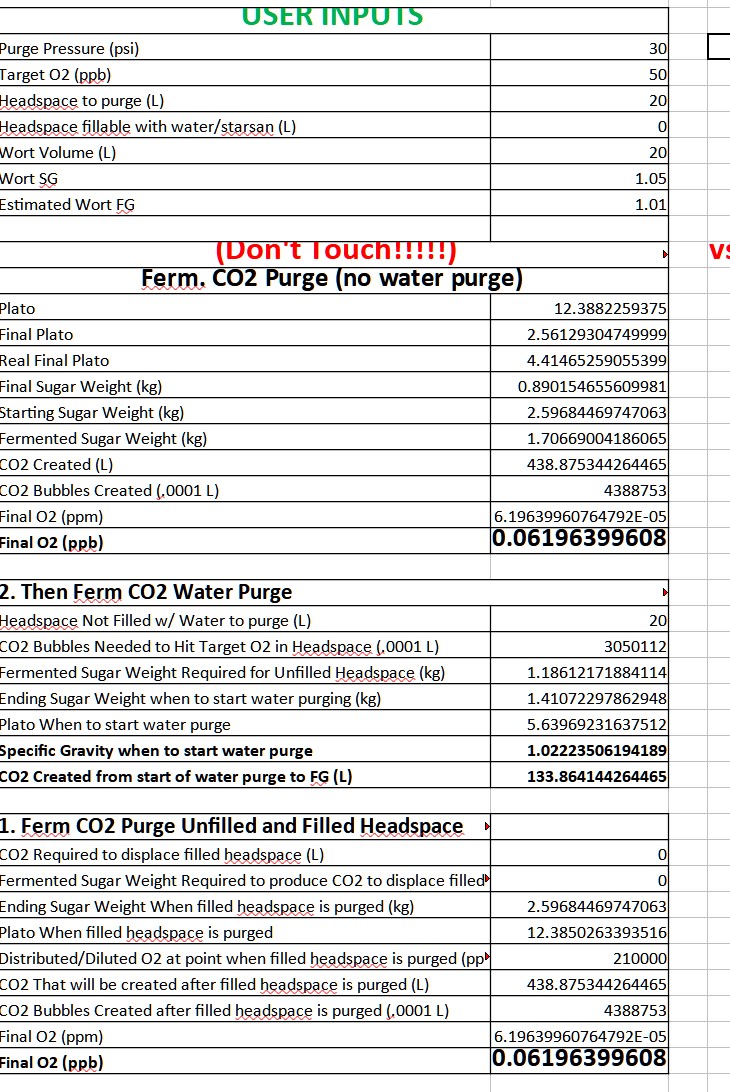

been nerding out on this for a while, figuring out how bad i've been leaving o2 around because i've been putting a spunding valve on my serving keg. the 2psi makes sure the lid stays sealed tight, which was a problem once before. however i believe that has the practical effect of massively increasing the "volume of co2" i need to do the purge. numbers are really bad.....Ok, a "5" gal corny has an actual volume of about 5.35 gal, so 2 of those plus 1.5 gal headspace in the fermenter totals 12.2 gal, or 46.2 liters. Assuming you have 20 liters of wort at 1.050 that finishes at 1.010, you would generate ~440 liters of CO2 during fermentation. After some multiple gas dilution cycles the final O2 concentration is about 15 ppb (0.015 ppm.) So, purging (2X) 5 gal kegs with a 5 gal ferment appears to give acceptable results.

Brew on

Not sure if you would actually end up with less air or not this way. The original statement assumed you filled a sealed keg thru the liquid post, with an open PRV valve, and an unconnected gas QD on the gas post. Might be possible to measure if there is a difference filling with the lid off and then closing up the keg, but you need a pretty accurate scale, about 0.1 oz resolution with a 52-53 lb total weight.was filling a keg with near boiling water to sanitize after a brett beer today, being careful about sealing it up, and i thought of this thread. i think this might be a pretty heavy overestimation.

if you fill the corny to the rim (assuming you also punch your poppets to get any diptubes filled with water) then there's no way for the full 3fl oz of air to get into the keg. due to the shape of the lid opening, you easily submerge at least half of the lid, probably closer to 2/3 of it if you're careful and deliberate. so its more like 1-ish fl oz of air trapped in there? the water (at the rim level) basically hits the lid right around where the prv stem is, which is roughly 2/3 of the lid area i'd wager.

so assuming that we're down to more like 310ppm when you start your liquid purge. by the math quoted above.

although looking at the purge chart, (didnt see the math to calculate specifically) it still seems like you'd need 8 purges at 30 to get to 50ppb....

Need a complete and concise description of what you are actually doing. I'm not seeing it from what you have posted already.running the numbers you cite above with the extra volume i'm getting like 15727 ppb of oxygen. which is horrible.

is that right, or did we goof somewhere?

First, it's *minimum* purity, and O2 isn't the only possible contaminant.so here's another question, and if the answer's here already by all means point it out- i didnt see it.

how do the purge charts account for co2 used to purge being impure ? here's an example. matheson, who supplies breweries and wineries locally, says they're equal or under 50ppm for food grade gas and 30ppm for beverage. thats 30000 to 50000ppb.

i assume it would need to be a fraction multiplied into the (14.7 + purge pressure) figure somehow......?

This^First, it's *minimum* purity, and O2 isn't the only possible contaminant.

and that^Second, your pressure gauge reading inaccuracy completely dwarfs a >= 0.01% error by several orders of magnitude.

True that. Given that the amount of CO2 in the headspace and beer is roughly equal per unit volume, the paranoid can calculate how much ~CO2 is drawn from the tank to carbonate ~50x the amount of the headspace.Also, if you're using commercial CO2 to carbonate and serve then the contaminating O2 in the CO2 tank is going to oxidize your beer even if you could somehow achieve a lower inital O2 concentration in the headspace.

I would love to see your math. You take 50 ppm o2 and shove it into a keg dozens of times and somehow it results in less than 50ppm? Very interesting. Please show your work.First, it's *minimum* purity, and O2 isn't the only possible contaminant.

Second, your pressure gauge reading inaccuracy completely dwarfs a >= 0.01% error by several orders of magnitude.

In other words, you *could* calculate that you need 5.0001 purge cycles instead of 5, but your pressure reading might be off and you actually need 4.5 or 5.5.

So, it doesn't affect the math to any meaningful degree.

Yes, it's minimum purity (maximum possible impurities.) I saw a paper a while back (and stupidly didn't keep a copy or link) that analyzed actual O2 levels in beverage grade CO2. The typical O2 content was about 50 ppB, IIRC. I suspect that suppliers don't routinely measure the actual impurity content, as the equipment and procedures are much more expensive than what is required to demonstrate "no more than 30 ppM."First, it's *minimum* purity, and O2 isn't the only possible contaminant.

Second, your pressure gauge reading inaccuracy completely dwarfs a >= 0.01% error by several orders of magnitude.

In other words, you *could* calculate that you need 5.0001 purge cycles instead of 5, but your pressure reading might be off and you actually need 4.5 or 5.5.

So, it doesn't affect the math to any meaningful degree.

And while we're riffing with the paranoid jam band, how much plain atmosphere do you have trapped between the gas disconnect and the post when you attach gas?

Nobody said anything about liquid. I’m talking about the gas purging charts. There’s no liquid involved.Also, you need to convert from ppm or ppb by volume in the gas to ppm or ppb by weight in the liquid solution, since that's what is ultimately going to damage your beer (or not). Gas is much more diffuse than liquid, so 50 ppm in a minimal headspace after purging is not going to give anywhere near 50 ppm dissolved in your beer.

The link I included for matheson is to their spec sheet for gas grades. It’s ppm. Post 218.Yes, it's minimum purity (maximum possible impurities.) I saw a paper a while back (and stupidly didn't keep a copy or link) that analyzed actual O2 levels in beverage grade CO2. The typical O2 content was about 50 ppB, IIRC. I suspect that suppliers don't routinely measure the actual impurity content, as the equipment and procedures are much more expensive than what is required to demonstrate "no more than 30 ppM."

Brew on :mug;

Also- look at matheson spec sheet. 50ppm for food grade. 30ppm for beverage. O2. Linked in post 218. The 0.1% of impurities is 1000ppm. Nobody said it was all o2.First, it's *minimum* purity, and O2 isn't the only possible contaminant.

Second, your pressure gauge reading inaccuracy completely dwarfs a >= 0.01% error by several orders of magnitude.

In other words, you *could* calculate that you need 5.0001 purge cycles instead of 5, but your pressure reading might be off and you actually need 4.5 or 5.5.

So, it doesn't affect the math to any meaningful degree.

OK, but why are you so worried about it? It's not an accurate represenntation of what is actually going to be impacting your beer.Nobody said anything about liquid. I’m talking about the gas purging charts. There’s no liquid involved.

As long as we're being this persnickety, the spec for their beverage grade is <= 30ppm; 50 ppm is the spec for the other grades.The link I included for matheson is to their spec sheet for gas grades. It’s ppm. Post 218.

No, the logical way to read it is that food grade is tested by a method with a limit of detection of 30 ppm and the other grades are tested by a method with a limit of detection of 50 ppm. At least that's what "<=" meant when I did product QA and QC for a living. If we had a test method that gave us a more precise result, we spec'd and reported the product that way.50ppm for food grade. 30ppm for beverage. O2. ...

... the idea that they would state 50ppm of o2 but give you gas with only 1ppm makes no sense. Why would they bother to even have those grades? The logical way to read it is that food grade is 30-50ppm. Beverage is X to 30ppm, where X is the max o2 level of the next higher grade.

You're right. I give up. Might as well just use a hand pump and a picnic tap from now on.Ask yourself this. How many vessels are filled in the supply chain before your tank is actually filled? Are they purging the co2 pump to tank connection 100% before each fill. I 1000% doubt it and if you look at the open ended rig used to fill your tank, a shipload of air is going in first and then the co2. I've watched it firsthand in horror.

Nice straw man.You're right. I give up. Might as well just use a hand pump and a picnic tap from now on.

Actually just a joke. I suppose by now I'd have learned that sarcasm doesn't work on the internet, but sometimes I just can't help myself. Guess I should have used one of them smiley thingies.Nice straw man.

I've read that ppm in the headspace translates to ppb in the beer. Maybe somebody with better math skills than me can show the work.If we're talking ppm or ppb it's an interesting point.

Do you then connect the gas upside down, or how do you prevent the "cup" in the disconnect from instantly being replaced by air? (or are you using some other disconnects besides ball lock?)Very little, I actually purge that. Tank on, ball valve on, press needle nose pliers into the disconnect for a few seconds. Burst that leftover air out (which is theoretically CO2 form the last time because I don't disconnect my lines, but it's PVC so I'm not counting on that for long).

I've never purged any other way. Clean keg, throw priming sugar in, hook up to the fermentation, wait some hours (or overnight) until the blowoff container smells like CO2, done. I also sometimes overprime a bit, so that I can spund some liters worth of gas to get rid of those pesky picograms of O2 that snuck into the keg during transfer. (or, some variation of the previous, depending on the beer, how long it will mature, and how long the anticipated consumption time is)I do need to try the fermentation purge.

The trick is in the definition of "ppx." For gases, it's the partial pressure of the gas (or parts per x by number of molecules, same thing.) So if the total CO2 pressure is 2 atm and you have 1 ppm O2, you have a partial pressure for O2 of 2e-6 atm. On the other hand, ppx in liquids is measured by mass, so 1 ppm O2 means 1 mg of O2 per kg of beer.I've read that ppm in he headspace translates to ppb in the beer. Maybe somebody with better math skills than me can show the work.