Octavius

Well-Known Member

- Joined

- Apr 13, 2009

- Messages

- 248

- Reaction score

- 3

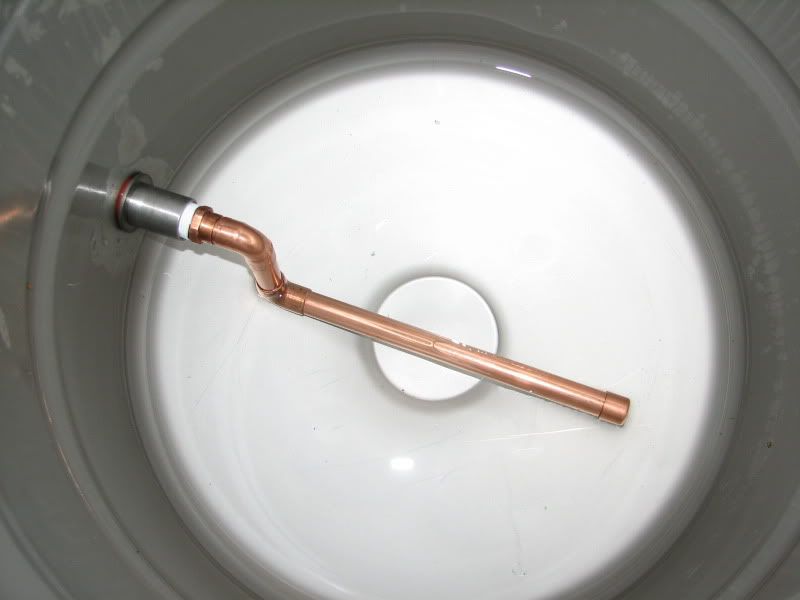

Of course there are slots on the underneath of the long tube.

None of this is soldered. I made it so the bottom elbow is pressing against the bottom of the keg - to stop it falling off.

I'm a bit bummed because, after draining and tilting the keg, there is still 5 pints left. Is this too much of a tithe to the Beer Gods?

I was kind of hoping there would be a syphoning effect but it stops at about the level of the bottom of the outlet.

It is not too late for me to make changes if anyone has a suggestion.

Cheers!